Taking device for water-quenching method for producing foam glass raw material

The technology of foam glass and water quenching method is applied in the field of glass manufacturing, which can solve the problems of high labor intensity of operators, difficult to control the amount of material, and high labor cost, and achieves the effect of eliminating potential safety hazards, realizing automatic continuous operation and easy maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

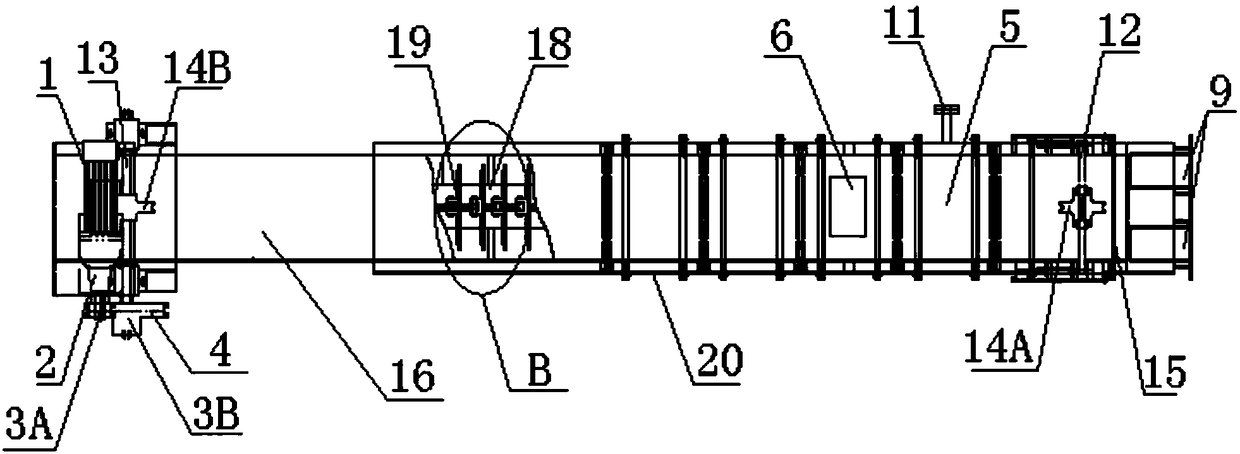

[0035] exist figure 1 In the shown embodiment, the tension adjustment mechanism 7 includes two hydraulic cylinders, the piston rods of the two hydraulic cylinders press against the bearing seats at both ends of the driven shaft (12), and the position of the driven shaft 12 can be fine-tuned through the hydraulic cylinders. The scraper chain 19 bypassing the driven shaft 12 is tensioned; in another embodiment, the tension adjustment mechanism 7 includes a tension roller arranged at the lower part of the scraper chain 19, and the upper surface of the tension roller presses the scraper chain 19. The tensioning roller can rotate with the scraper chain 19. Both ends of the tensioning roller are equipped with adjustable lifting mechanisms. By fine-tuning the position of the tensioning roller to adjust the degree of compression of the tensioning roller on the scraper chain 19, thereby Ensure that the scraper chain 19 remains in tension and does not break away.

[0036] Further, beca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com