Preparation method of 3D-graphene material using biomass resources as carbon source

A technology of biomass resources and graphene, which is applied in the field of preparation of 3D-graphene materials, can solve the problems of complex operation, no patent publications, and high production costs, and achieve good biocompatibility, low cost, and good conductivity rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

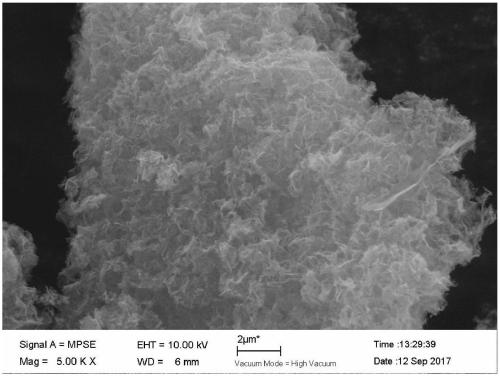

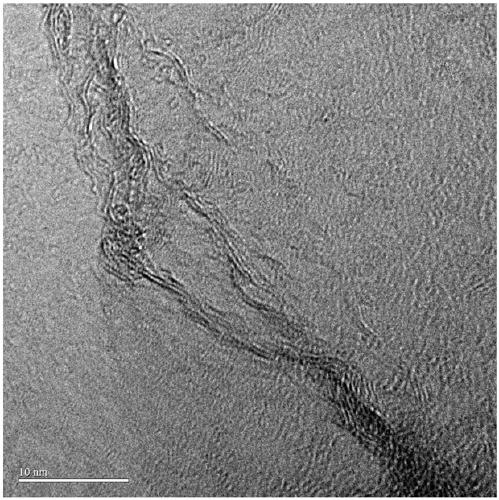

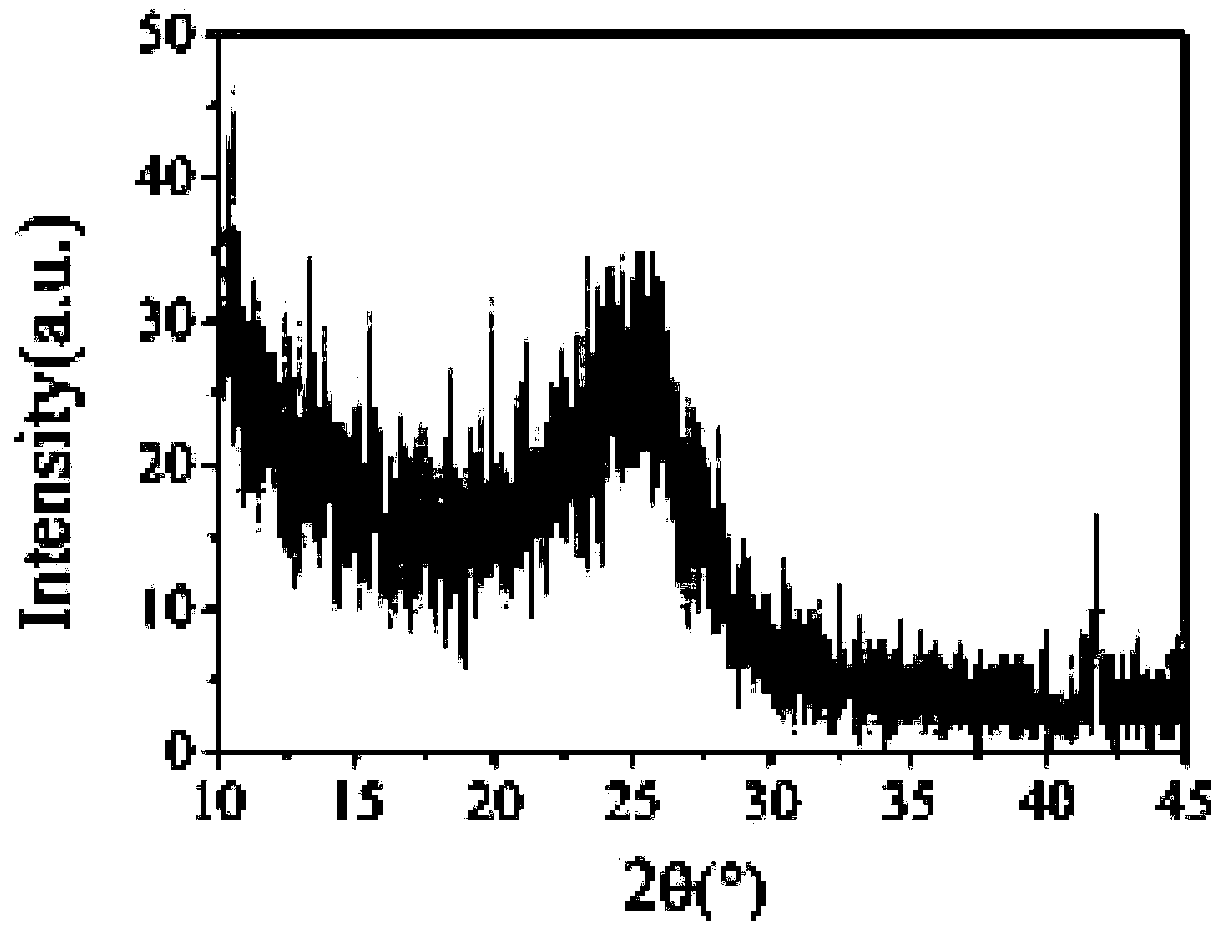

[0033] A method for preparing a 3D-graphene material using protein as a carbon source, the steps are as follows:

[0034] (1) Dissolve bovine serum albumin in an aqueous solution, stir at 20°C to dissolve it, add sodium sulfate, continue stirring until it forms a uniform solution, titrate the above liquid into ethanol with a syringe pump (titration speed 200ul / min), and obtain White solid, dried in a vacuum oven at 80°C to 120°C for 4 to 12 hours to obtain a mixture of bovine serum albumin and salt;

[0035] Wherein, the mass ratio of described bovine serum albumin and salt is 1:3;

[0036] (2) Put the mixture of protein and salt in step (1) into a tube furnace for carbonization, disperse the carbonized sample in water, and filter to obtain a black solid, which is a 3D-graphene material.

[0037] The heating program is as follows: from room temperature to 300°C at 2°C / min and maintained for 2 hours, then raised to 500°C at 3°C / min and maintained for 1 hour.

Embodiment 2

[0039] A kind of preparation method using glycine as the 3D-graphene material of carbon source, the steps are as follows:

[0040] (1) Dissolve glycine in the aqueous solution, stir to dissolve at 20°C, add potassium chloride, continue to stir until it forms a uniform solution, titrate the above liquid into isopropanol with a syringe pump (titration speed 300ul / min), Obtain a white solid, and dry it in a vacuum oven at 80°C to 120°C for 4 to 12 hours to obtain a mixture of glycine and salt;

[0041] Wherein, the mass ratio of described glycine and salt is 1:5;

[0042] (2) Put the mixture of glycine and salt in step (1) into a tube furnace for carbonization, disperse the carbonized sample in water, and filter to obtain a black solid, which is a 3D-graphene material.

[0043] The heating program is as follows: from room temperature to 200°C at 3°C / min and maintained for 1-2 hours, then raised to 600°C at 1°C / min and maintained for 1-2 hours.

Embodiment 3

[0045] A kind of preparation method using glutamic acid as carbon source 3D-graphene material, the steps are as follows:

[0046] ⑴Dissolve glutamic acid in aqueous solution, stir at room temperature (25°C) to dissolve, add copper sulfate, continue stirring until it forms a uniform solution, titrate the above liquid into isopropanol with a syringe pump (titration speed 500ul / min) to obtain a white solid, which was dried in a vacuum oven at 80°C to 120°C for 4 to 12 hours to obtain a mixture of glutamic acid and salt;

[0047] Wherein, the mass ratio of glutamic acid and salt is 1:8;

[0048] (2) Put the mixture of glutamic acid and salt in step (1) into a tube furnace for carbonization, disperse the carbonized sample in water, and filter to obtain a black solid, which is a 3D-graphene material.

[0049] The heating program is as follows: from room temperature to 350°C at 2°C / min and maintained for 1-2 hours, then raised to 700°C at 3°C / min and maintained for 1-2 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com