High-accuracy automatic film pasting device for large-tolerance incoming material

A film sticking device and high-quality technology, which is applied in the field of high-precision automatic film sticking devices for large-tolerance incoming materials, can solve the problems of affecting the market share of products, inconsistent filming positions, and high production costs, so as to improve market competitiveness and product quality. Good, low production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

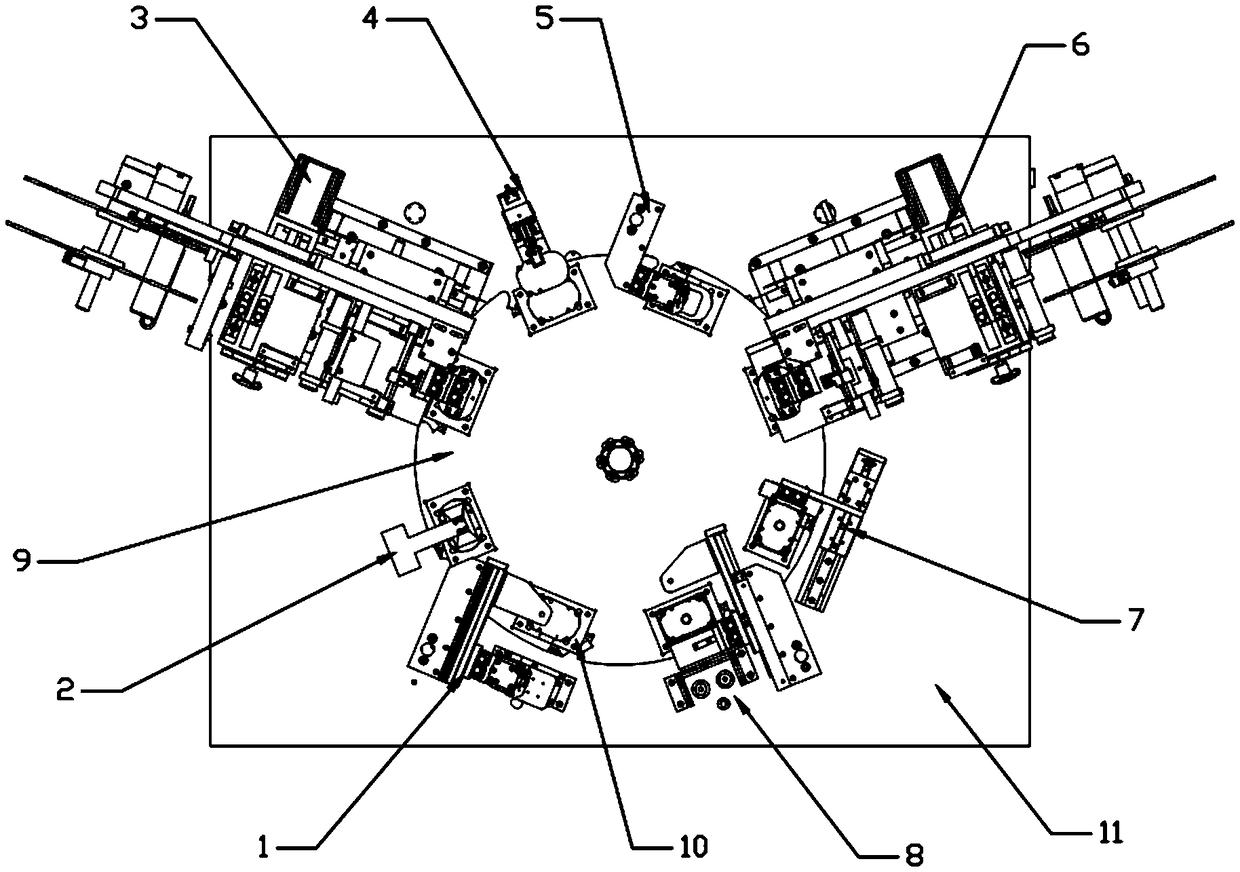

[0025] In the specific implementation of the present invention, a high-precision automatic film sticking device with large tolerance incoming materials includes a material feeding station 1, a cleaning station 2, a reverse labeling machine 3, a flipping station 4, a positioning station 5, and a front labeling station. Machine 6, leveling station 7, discharging station 8 and center turntable 9, the upper outer edge of the center turntable 9 is evenly provided with eight magnetic sheet carriers 10 along the circumference, the feeding station 1, Cleaning station 2, reverse labeling machine 3, flipping station 4, positioning station 5, front labeling machine 6, leveling station 7 and discharging station 8 are uniformly arranged in sequence along the circumferential direction of the central turntable 9. The center of the center turntable 9 is provided with a drivi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com