Micro-control device for reducing plate anchor burial depth loss and construction method of micro-control device

A flat anchor and micro-control technology, which is applied to anchor points, transportation and packaging, ship parts, etc., can solve the problems of large buried depth loss, achieve the effects of reducing buried depth loss, high cost performance, and improving bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

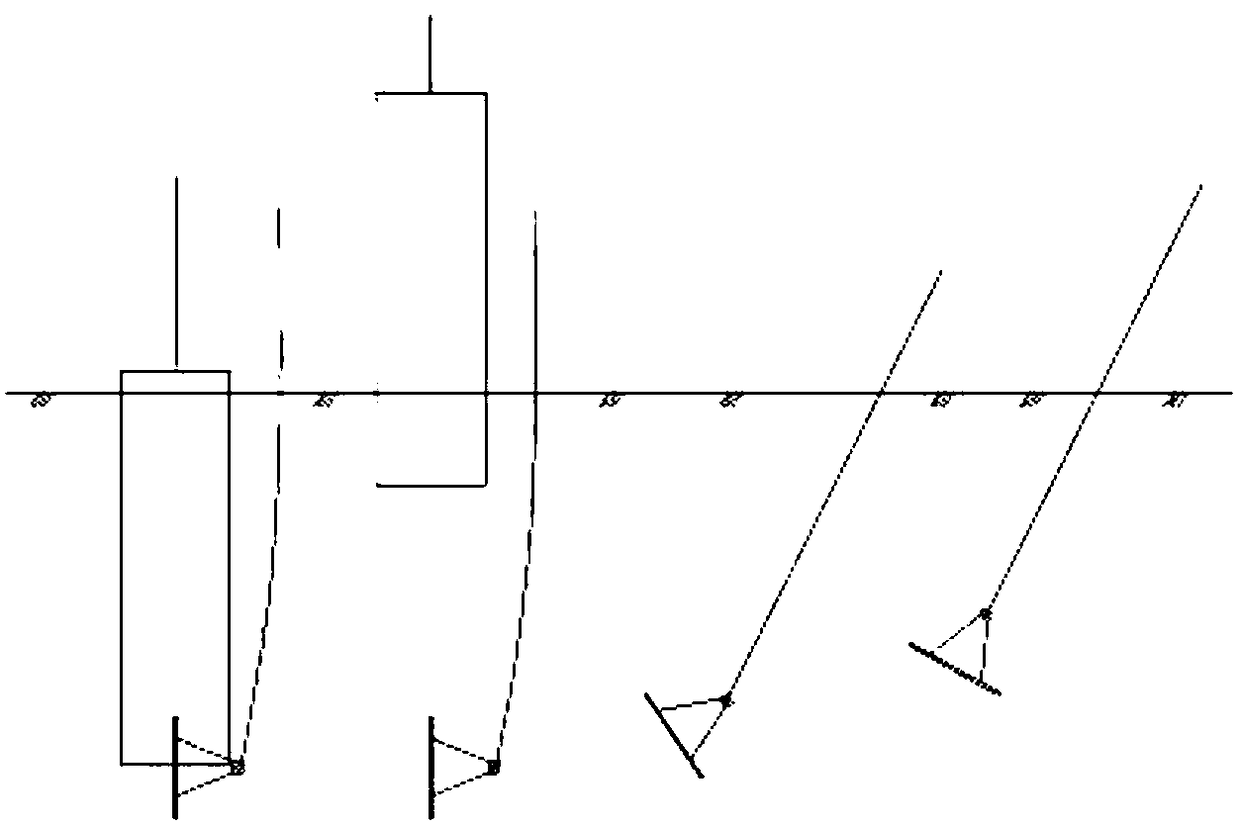

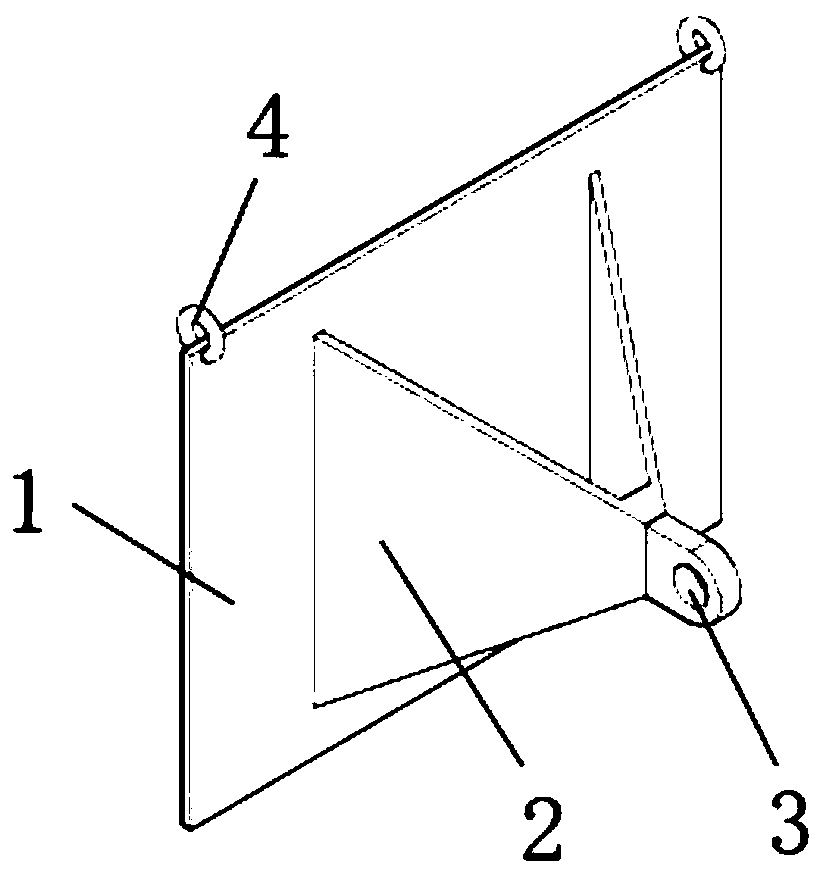

[0044] See attached picture.

[0045] A micro-control device for reducing the burial depth loss of a flat anchor, comprising a flat anchor composed of an anchor plate 1 and an anchor handle 2, the end of the anchor handle has an anchor eye 3, and mooring rings 4 are arranged at the corners on both sides of the upper part of the anchor plate 1, It also includes two steel rods 5 with mooring rings 6 at one end, and the mooring rings 6 of each steel rod 5 are respectively connected to one of the mooring rings 4 through steel cables 7;

[0046] Also includes the barrel foundation 8, the bottom of the barrel foundation 8 is provided with the anchor plate bayonet 8 and the anchor handle bayonet 10 respectively matched with the head of the anchor plate 1 and the anchor handle 2, and the anchor eye 3 exposes the barrel foundation 8; A sleeve 12 matching with the steel rod 5 is arranged on the outer wall of the barrel-shaped foundation 8 directly above the plate bayonet 9;

[0047] Wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com