Anti-rib-forming and anti-wrinkling printing film and preparation method thereof

A technology of printing film and rib, applied in the field of anti-riot rib and anti-wrinkle printing film and its preparation, can solve the problems of high anti-riot rib, difficult to master process technology, etc., to achieve the effect of good flexibility and ensure sliding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

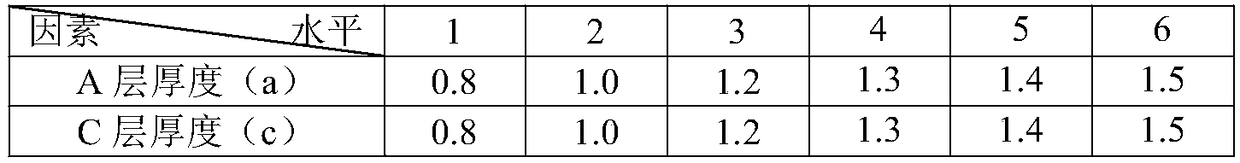

[0067] An anti-riot rib anti-wrinkle printing film has an ABC layered composite structure.

[0068] Layers A and C are surface layers, both containing 96.5% propylene-ethylene binary copolymer, 1% stearic acid amide, 0.5% calcium carbonate and 2% di-p-methylbenzylidene sorbitol, A layer The thickness is 0.8 μm, the thickness of C layer is 1.2 μm; the B layer is the core layer, containing 89% homopolypropylene resin, 10% aliphatic petroleum resin (C5) and 1% monoglyceride, and the thickness is 20 μm. The total thickness of the printed film was 22 μm.

[0069] A method for preparing the above-mentioned anti-riot rib anti-wrinkle printing film, adopts the following steps:

[0070] S1. Weigh and configure core layer raw materials and surface layer raw materials respectively according to mass percentage:

[0071] Core material:

[0072] Homopolypropylene resin 89%,

[0073] Aliphatic petroleum resin (C5) 10%,

[0074] Monoglyceride 1%;

[0075] Surface material:

[0076] Pro...

Embodiment 2

[0089] An anti-riot rib anti-wrinkle printing film has an ABC layered composite structure.

[0090] Layer A and Layer C are the surface layers, both containing 98.4% propylene-ethylene copolymer, 0.5% silicone oil, 0.1% barium sulfate and 1% dibenzylidene sorbitol, the thickness of A layer is 1 μm, and the thickness of C layer The thickness is 1.5 μm; layer B is the core layer, containing 99% homopolypropylene resin, 0.5% alicyclic resin (DCPD) and 0.5% ethoxylated amine, and the thickness is 25 μm. The total thickness of the printed film was 27.5 μm.

[0091] A method for preparing the above-mentioned anti-riot rib anti-wrinkle printing film, adopts the following steps:

[0092] S1. Weigh and configure core layer raw materials and surface layer raw materials respectively according to mass percentage:

[0093] Core material:

[0094] Homopolypropylene resin 99%,

[0095] Cycloaliphatic resin (DCPD) 0.5%,

[0096] Ethoxylated amine 0.5%;

[0097] Surface material:

[009...

Embodiment 3

[0111] An anti-riot rib anti-wrinkle printing film has an ABC layered composite structure.

[0112]Layer A and Layer C are the surface layers, both containing 97.3% propylene-ethylene copolymer, 0.8% erucamide, 0.3% silicone and 1.6% 3,4-dimethyldibenzylidene sorbitol , the thickness of layer A is 0.9 μm, the thickness of layer C is 1.35 μm; layer B is the core layer, containing 95% homopolypropylene resin, 4.2% aromatic resin (C9) and 0.8% 2-hydroxyethyl fat Amide with a thickness of 22.5 μm. The total thickness of the printed film was 24.75 μm.

[0113] A method for preparing the above-mentioned anti-riot rib anti-wrinkle printing film, adopts the following steps:

[0114] S1. Weigh and configure core layer raw materials and surface layer raw materials respectively according to mass percentage:

[0115] Core material:

[0116] Homopolypropylene resin 95%,

[0117] Aromatic resin (C9) 4.2%,

[0118] 2-Hydroxyethyl fatty acid amide 0.8%;

[0119] Surface material:

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com