High-precision superposition technology of shrink fit cylinder for pressure container

A pressure vessel and thermal sleeve technology, applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve problems such as difficult control of precision, delay in construction period, non-conforming quality of fitting surfaces, etc. Quick and precise alignment for a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

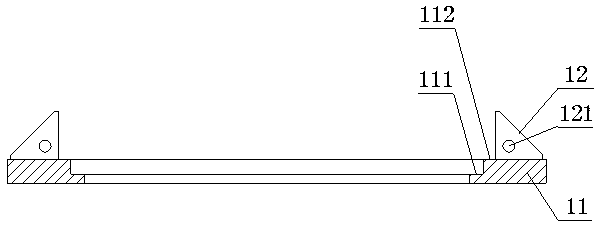

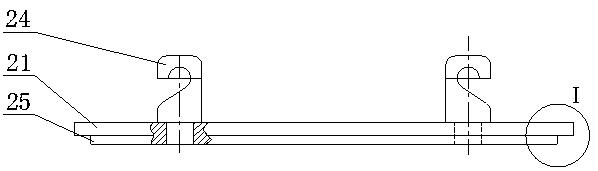

[0024] Embodiment 1: The high-precision fitting process of a thermal sleeve body for a pressure vessel described in Embodiment 1, the material of the outer cylinder is 16MnR, the inner diameter is 1000mm, the wall thickness is 30mm, and the material of the lining cylinder is 13MnNiMoR , the outer diameter is 1002mm, and the wall thickness is 10mm. The trial production of the thermal sleeve body mainly includes the following steps:

[0025] ① Manufacture of the outer cylinder 1: After blanking, rounding, longitudinal seam welding, and rounding of the plate, the outer cylinder 1 with an inner diameter of 1000mm is produced. The roundness of the outer cylinder 1 is less than 2mm, and the straightness is less than 1mm. The parallelism of the end face is less than 1mm;

[0026] ②Manufacturing of the lining cylinder 2: The lining cylinder 2 with an outer diameter of 1002 is produced after cutting, rolling, longitudinal seam welding, and rounding of the lining plate. The roundness of...

Embodiment 2

[0037] Embodiment 2 In the high-precision fitting process of a thermal sleeve body for a pressure vessel described in Embodiment 2, the material of the outer cylinder is Q245R, the inner diameter is 400mm, the wall thickness is 35mm, and the material of the lining cylinder is 14MnMoNbB. The outer diameter is 401mm, the wall thickness is 30mm, and the trial production of the thermal sleeve body mainly includes the following steps:

[0038] ① Manufacture of the outer cylinder 1: The outer cylinder 1 with an inner diameter of 400mm is produced after blanking, rolling, longitudinal seam welding, and circle adjustment of the plate. The roundness of the outer cylinder 1 is less than 0.8mm, and the straightness is less than 1mm , the parallelism of the end face is less than 1mm;

[0039] ②Manufacturing of the lining cylinder 2: The lining cylinder 2 with an outer diameter of 401 is obtained after cutting, rolling, longitudinal seam welding, and rounding of the lining plate. The round...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Straightness | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com