Method for local cooling of investment casting formwork

A technology of investment casting and local cooling, which is applied in the direction of casting molding equipment, molds, mold components, etc., can solve the problems of easy shrinkage, large feeding amount, and reduced casting process yield, so as to prevent shrinkage , Improve the feeding effect, improve the effect of quality and process yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

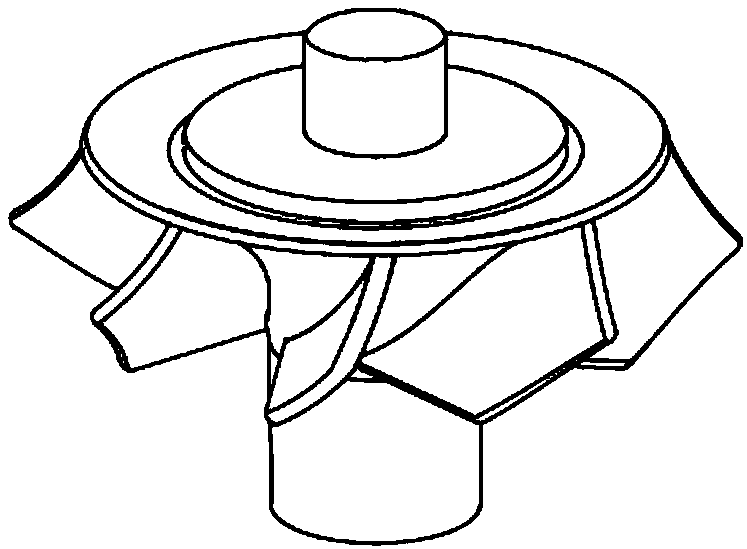

[0040] A large turbine with a size of Φ425×298mm has 8 uniformly distributed blades, the blank weight is 65Kg, and the material is stainless steel, such as figure 1 shown;

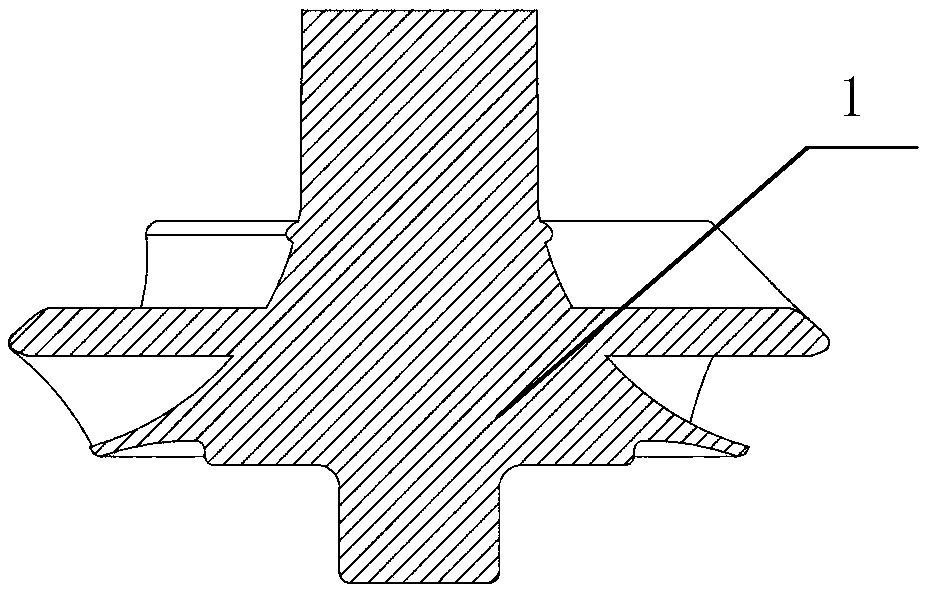

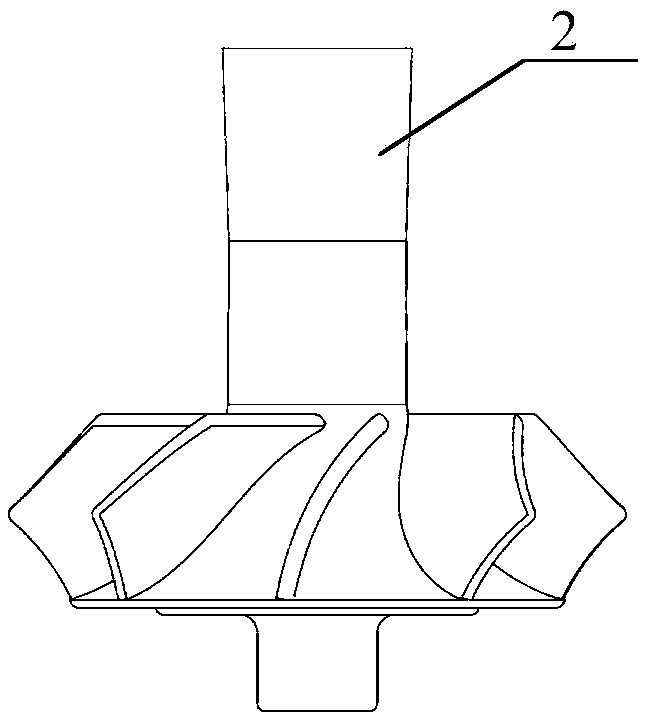

[0041] First analyze the structure of the turbine casting, choose the riser top pouring gating system, such as figure 1 As shown, the upper end face of the turbine needs to be friction welded, so the internal structure requirements of this position are relatively high, so the position of the sprue and riser cannot be set here, only the choice of figure 2 The lower end surface is used as the riser surface, such as image 3 As shown, the size of the riser is Φ120×100mm, such as Figure 4 Shown, turbine casting and riser formwork.

[0042] figure 2 middle position is figure 1 During the solidification process of the molten metal, this position solidifies slowly, and the molten metal cannot be fully fed, and the feeding effect is poor; therefore, an external tooling is designed at the position of the ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com