Face cleaning mousse and preparation method thereof

A technology of cleansing and surfactant, applied in the field of cleansing mousse and its preparation, can solve the problems of insignificant effect, allergic phenomenon, unsuitable for people with sensitive skin, etc., and achieve the effect of improving dull skin and broad market prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

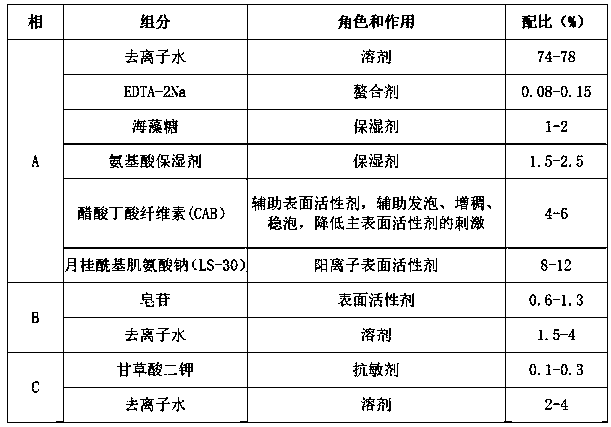

[0036] see figure 1 , a cleansing mousse, the raw materials are calculated according to the weight percentage, including the following components:

[0037] Phase A: Deionized water 74-78%, chelating agent 0.08-0.15%, humectant 2.5-4.5%, cellulose acetate butyrate 4-6%, sodium lauroyl sarcosinate 8-12%, lauroyl sarcosine Sodium is an auxiliary surfactant, which assists foaming, thickening and foam stabilization, and reduces the stimulation of the main surfactant;

[0038] Phase B: surfactant 0.6-1.3%, deionized water 1.5-4%;

[0039] Phase C: Anti-sensitizer 0.1-0.3%, deionized water 2-4%.

[0040] The chelating agent is EDTA-2Na. EDTA-2Na can form stable chelates with almost all metal ions. The humectant includes trehalose and amino acid humectant. The weight percentage of trehalose is 1-2%, and the weight of amino acid humectant is 1-2%. The percentage is 1.5-2.5%. Trehalose has excellent properties of maintaining cell vitality and biological macromolecular activity, effec...

Embodiment 2

[0049] 1. Clean and disinfect the required tools;

[0050]2. Prepare to weigh phase A and add it to the oil phase pot. In phase A, deionized water 74.7%, EDTA-2Na 0.3%, trehalose 1%, amino acid moisturizing agent 3%, cellulose acetate butyrate 4.8%, laurel Sodium acyl sarcosinate 10%, heat up to 80-85°C, add phase B to the water phase pot, add saponin 0.8% in phase B, deionized water 2.2%, stir and heat up to 85-90°C, phase A, phase B Stir until completely dissolved, keep warm for 10-15 minutes;

[0051] 3. Pump phase A into phase B, homogenize under vacuum for 3-5 minutes, add phase C and homogenize under vacuum for 3-5 minutes until completely dissolved, in phase C, dipotassium glycyrrhizate 0.5%, deionized water 3.3%;

[0052] 4. Keep the temperature constant for 10-15 minutes after defoaming and then cool down, stir evenly when the temperature is below 45 degrees, and discharge after the plate is qualified.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com