Water dividing valve assembly and layered dishwasher with same

A water-splitting valve and dishwasher technology, which is used in dishwashing machines/washing machines, cleaning devices, household cleaning devices, etc., can solve the problems of secondary pollution, energy efficiency, waste, large cavity volume, etc. The effect of shortened utilization time, reduced water intake time, and reduced requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further explained below in conjunction with specific embodiments.

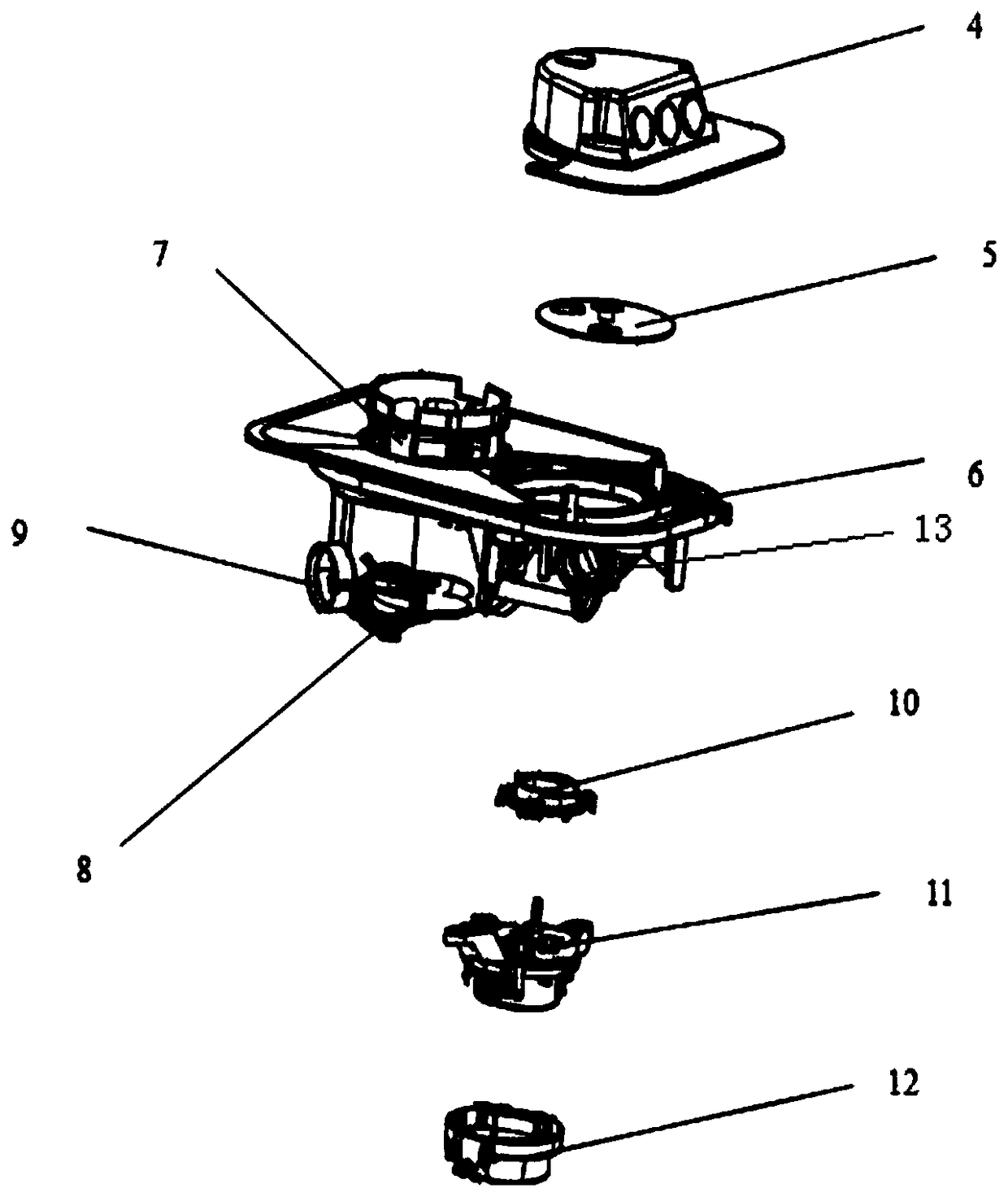

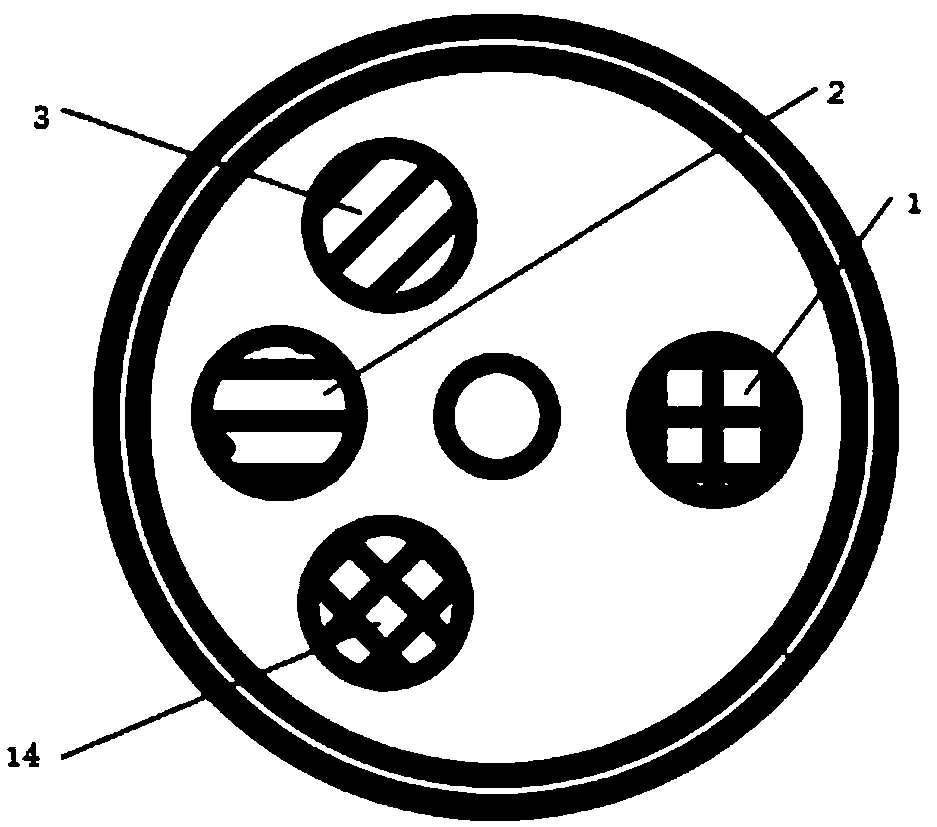

[0043] refer to Figure 1-4, a water diversion valve assembly, comprising a distributor main body, a clean water inlet is provided on one side of the distributor main body, a distributor motor is provided at the lower end of the clean water inlet, and the distributor motor is installed in a motor box, the The upper end of the motor box is provided with a motor cover, and the upper end of the pipeline connected with the clean water inlet is provided with a water flow distribution rotor, a water flow distribution stator and a distributor cover, and the water flow distribution rotor and the water flow distribution stator are located inside the distributor cover, and the water flow distribution The rotor and the water flow distribution stator are provided with matching through holes, the side of the distributor cover is provided with a fruit and vegetable box waterway, an upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com