Automatic bread maker and control method

A bread machine, automatic technology, applied in the direction of toasting device, household utensils, applications, etc., can solve the problems of inconvenience, adverse effects of the normal operation of the material box and other mechanisms, and multi-operation of the top parts, so as to avoid dust pollution and reduce manual intervention Or the need for participation, the effect of reducing the burden of opening and closing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

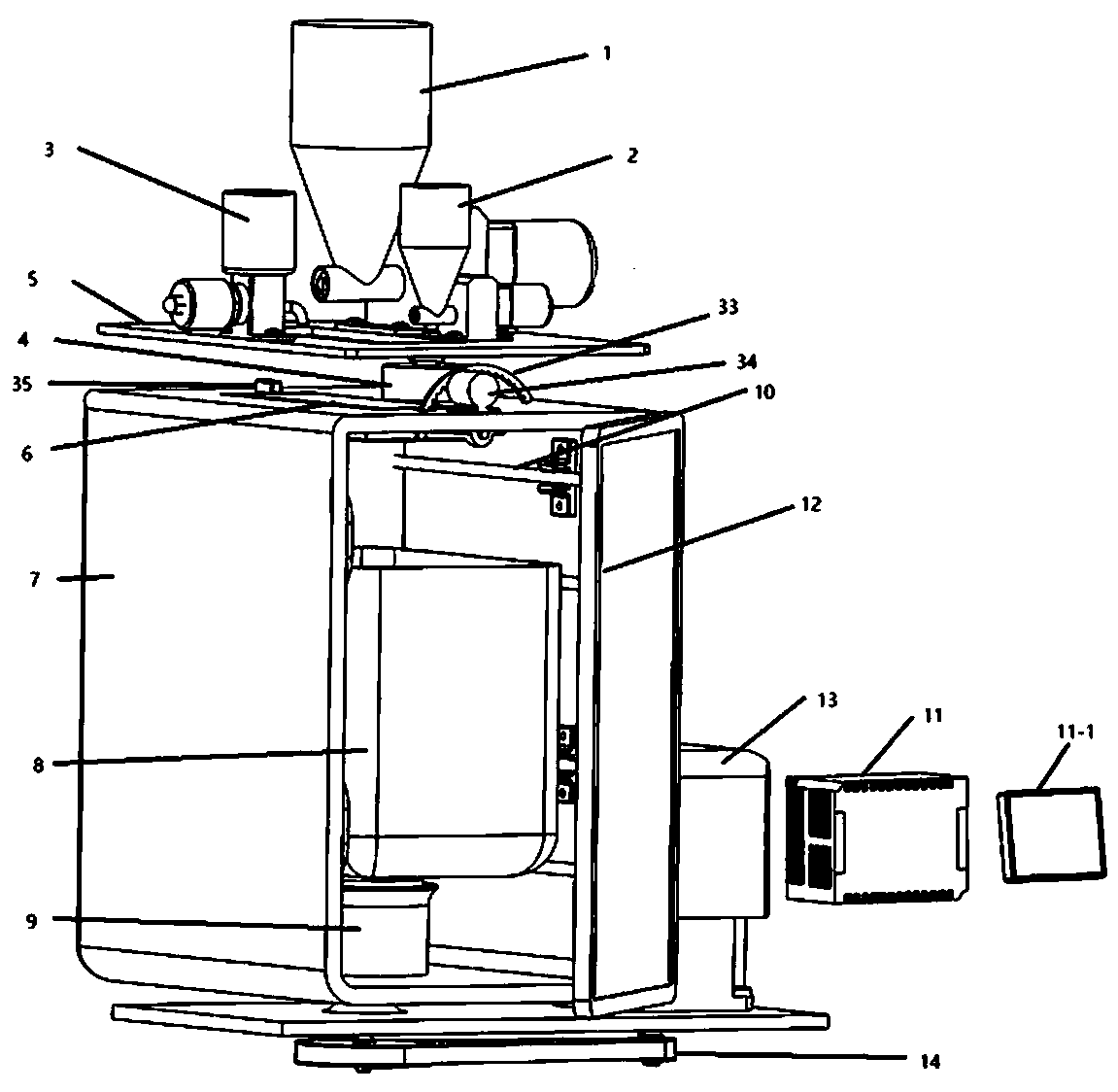

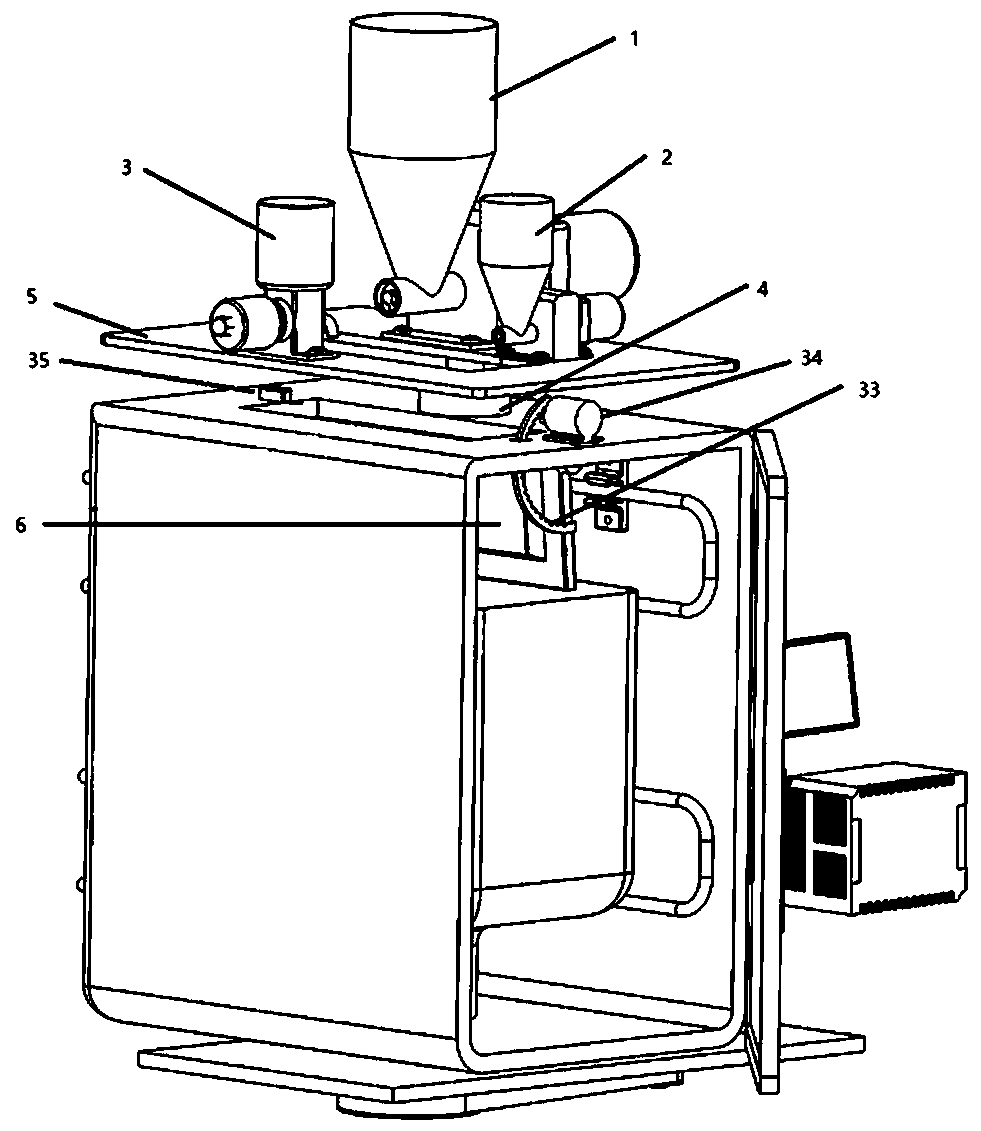

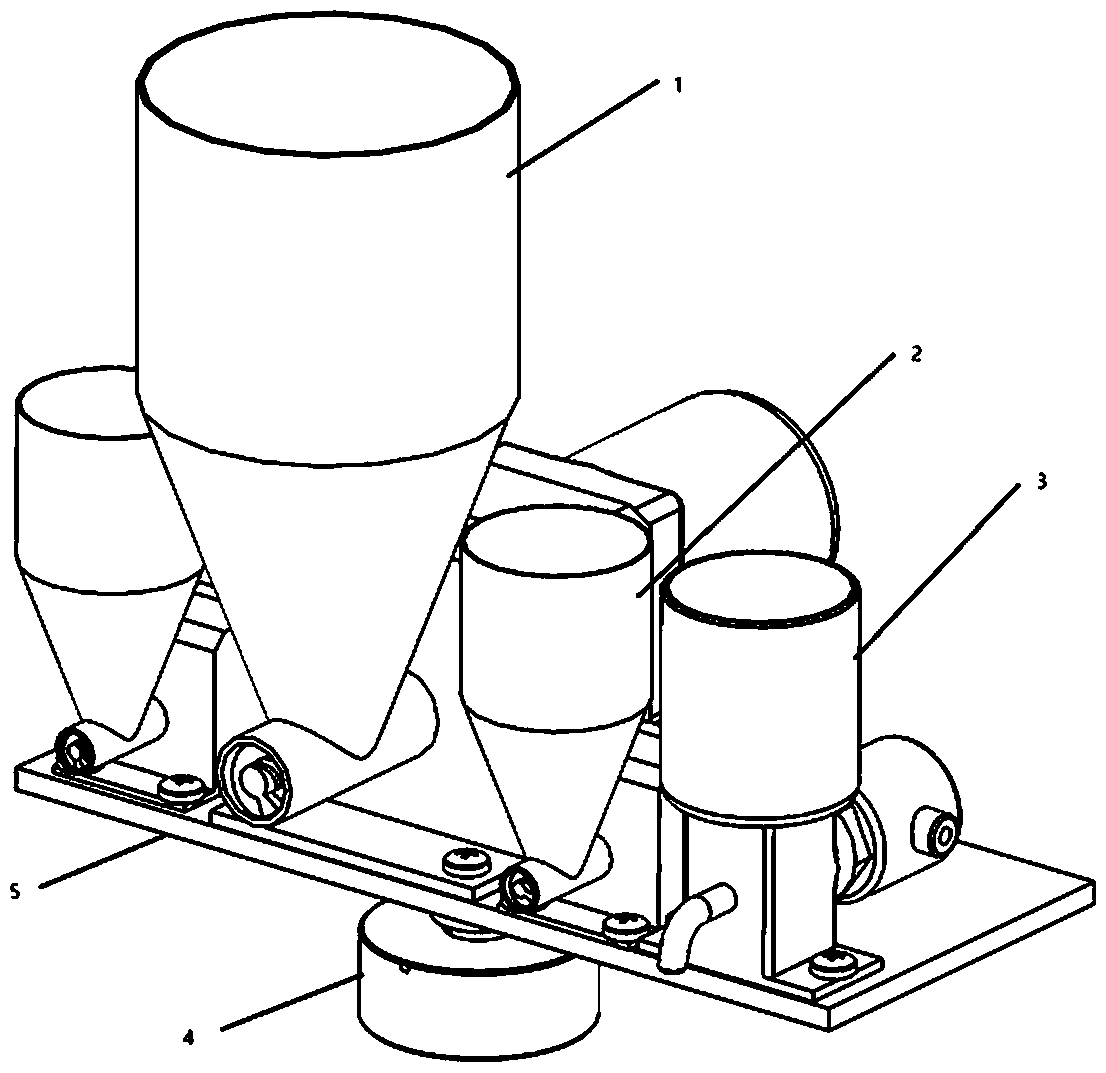

[0075] Such as Figure 1 to Figure 1 Shown in -4, a kind of automatic bread machine comprises control center 11, casing 7, the cooking container 8 that is located at the middle part of casing 7, metering device and the feeding device that throws material in cooking container 8.

[0076] The box body 7 is square, with a heating system inside, and the heating system includes an oven temperature sensor T1 and a plurality of heaters 10 located on the inner wall of the box body 7; the oven temperature sensor T1 is set in a similar manner to that of an ordinary bread machine The interior of the heating system forms a baking cavity; the cooking container 8 is located in the baking cavity, which is a square bucket-shaped container for storing bread raw materials, and is also a subsequent dough stirring, fermentation and baking container. The inner bottom of the casing 7 is provided with a base 9 for placing the cooking container 8, and the outer bottom is provided with a power transmi...

Embodiment 2

[0104] Present embodiment also provides a kind of automatic bread machine; Its basic structure is similar to embodiment 1, difference is:

[0105] The feeding device also includes a lifting device arranged in the box body 7; the lifting device is used to lift the cooking container 8, and includes a lifting part 16 and a lifting part. The lifting part is used to lift the cooking container 8, and the lifting part 16 is used to drive the lifting part and the weight sensor 4, and can adopt a rack and pinion mechanism, a screw nut mechanism, a turbine screw mechanism, a ball screw mechanism, a guide rail chain mechanism, The guide rail synchronous belt mechanism, the hydraulic cylinder mechanism, the cam mechanism, the scissor lifting component 16 or other lifting components 16 that can achieve the same effect are provided with a lifting platform 17, and the weight sensor 4 is located on the lifting platform 17.

[0106] The weight sensor 4 can be in S-type, cantilever-type, spoke-...

Embodiment 3

[0126] Present embodiment also provides a kind of automatic bread machine; Its basic structure is similar to embodiment 1, difference is:

[0127] The charging device also includes at least one metering barrel 25; the feed port of the metering barrel 25 corresponds to or connects with the discharge port 30 of the conveying assembly, and is provided with a position corresponding to the feeding door 6 and the cooking container 8. The movable bottom door 26; the movable bottom door 26 is also an electric structure controlled by the control center 11 to open and close.

[0128] The control structure of the movable bottom door 26 of the metering barrel 25 can adopt a common electric opening and closing structure in the prior art, for example, the movable bottom door 26 is hingedly installed, and the rotating shaft of the hinge is fixed with the movable bottom door 26 (integrated or welding), the end of the rotating shaft is fixed coaxially with the output shaft of the motor (coupli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com