Fermented feed for lactating cows

A technology for fermented feed and dairy cows, which is applied in animal feed, animal feed, lactobacillus, etc., can solve the problems of alfalfa and oat usage, such as large demand, and achieve the effects of reducing dependence, good proliferation, and prolonging the storage period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

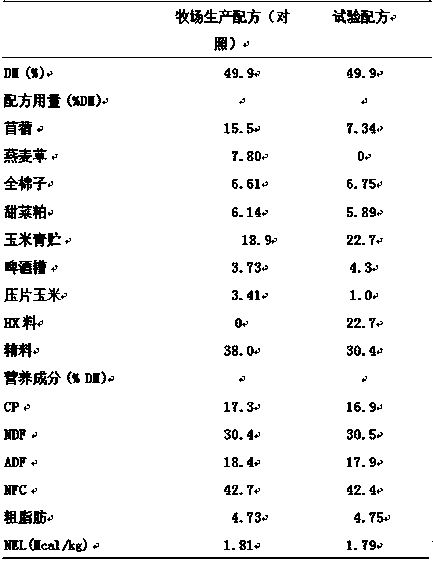

Embodiment 1

[0040] Formula: 6.93% alfalfa, 9.2% oat grass, 20.96% rice straw, 1.55% molasses, 23.69% corn, 3.72% corn germ meal, 7.29% brewer's grains, 9.11% soybean meal, 2.06% premix, 15.49% water The production formula is produced, and the theoretical moisture content of the formula is 36%. Input the formula into the control system in the central control room, calculate according to the demand of 30 tons of HX material, the feeding amount of each raw material is: 2425.5kg alfalfa, 3220kg oat grass, 7336kg rice straw, 542.5kg molasses, 8291.5kg corn, 1302kg corn Germ meal, 2551.5kg brewer's grains, 3188.5kg soybean meal, 721kg premix and 5421.5kg water. After confirming the feeding amount, feeding and pre-cutting are carried out according to the types of raw materials, and the feeding amount of each raw material is weighed, recorded and reviewed. Before the official production, check the machine to ensure the normal operation of the machine, and wash the warehouse with fresh raw materi...

Embodiment 2

[0042]Formula: 6.93% alfalfa, 9.2% oat grass, 20.96% rice straw, 1.55% molasses, 23.69% corn, 3.72% corn germ meal, 7.29% brewer's grains, 9.11% soybean meal, 2.06% premix, 15.49% water The production formula is produced, and the theoretical moisture content of the formula is 36%. Input the formula into the control system in the central control room, calculate according to the demand of 55 tons of HX material, the feeding amount of each raw material is: 3811.5kg alfalfa, 5060kg oat grass, 11528kg rice straw, 852.5kg molasses, 13029.5kg corn, 2046kg corn Germ meal, 4009.5kg brewer's grains, 5010.5kg soybean meal, 1133kg premix and 8519.5kg water. After confirming the feeding amount, feeding and pre-cutting are carried out according to the types of raw materials, and the feeding amount of each raw material is weighed, recorded and reviewed. Before the official production, check the machine to ensure the normal operation of the machine, and wash the warehouse with fresh raw mate...

Embodiment 3

[0044] Formula: 6.93% alfalfa, 9.2% oat grass, 20.96% rice straw, 1.55% molasses, 23.69% corn, 3.72% corn germ meal, 7.29% brewer's grains, 9.11% soybean meal, 2.06% premix, 15.49% water The production formula is produced, and the theoretical moisture content of the formula is 36%. Input the formula into the control system in the central control room, calculate according to the demand of 80 tons of TMF, the feeding amount of each raw material is: 5544kg alfalfa, 7360kg oat grass, 16768kg rice straw, 1240kg molasses, 18952kg corn, 2976kg corn germ meal, 5832kg Brewer's grains, 7288kg soybean meal, 1648kg premix and 12392kg water. After confirming the feeding amount, feeding and pre-cutting are carried out according to the types of raw materials, and the feeding amount of each raw material is weighed, recorded and reviewed. Before the official production, check the machine to ensure the normal operation of the machine, and wash the warehouse with fresh raw materials to prevent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com