Light emitting device, backlight module applying the same, light source module and preparation method thereof

A technology of light emitting device and light source module, which is applied in the direction of electrical components, electric solid devices, circuits, etc., and can solve the problems of reducing the luminous brightness and luminous efficiency of the light emitting device, side light leakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

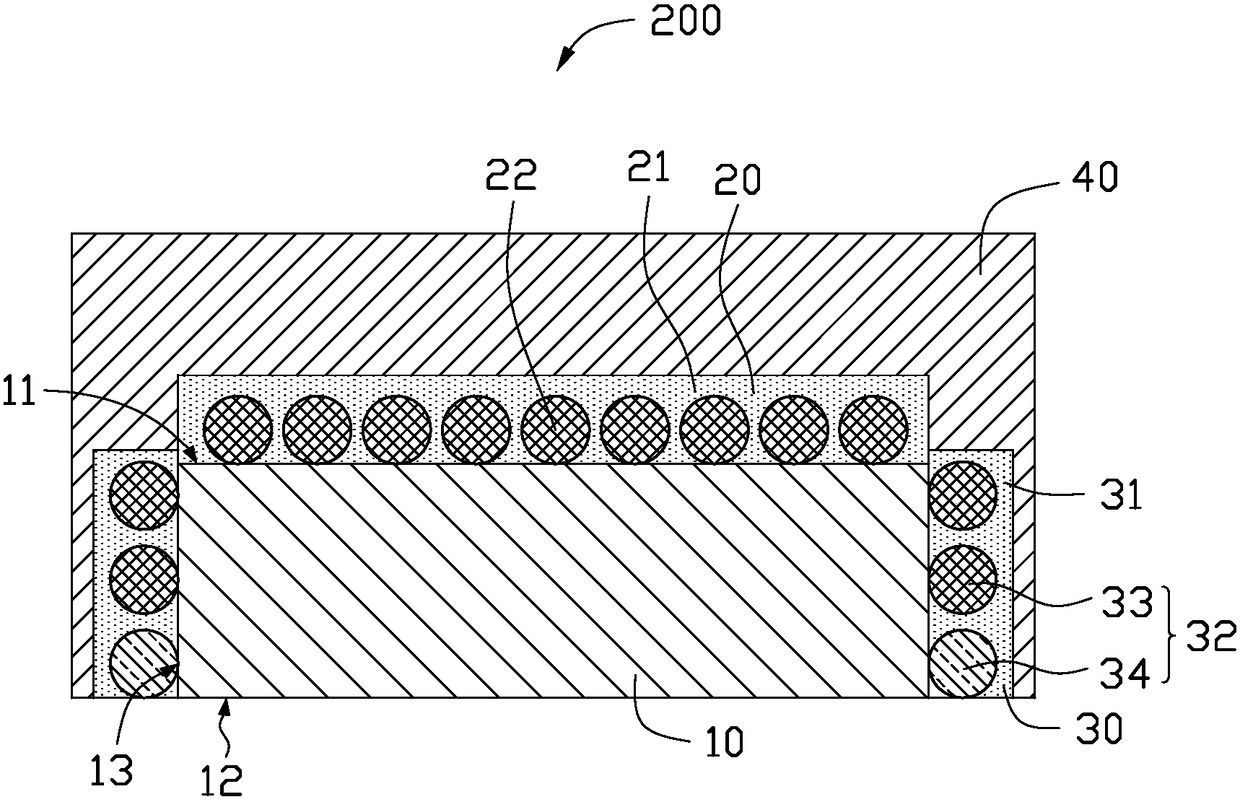

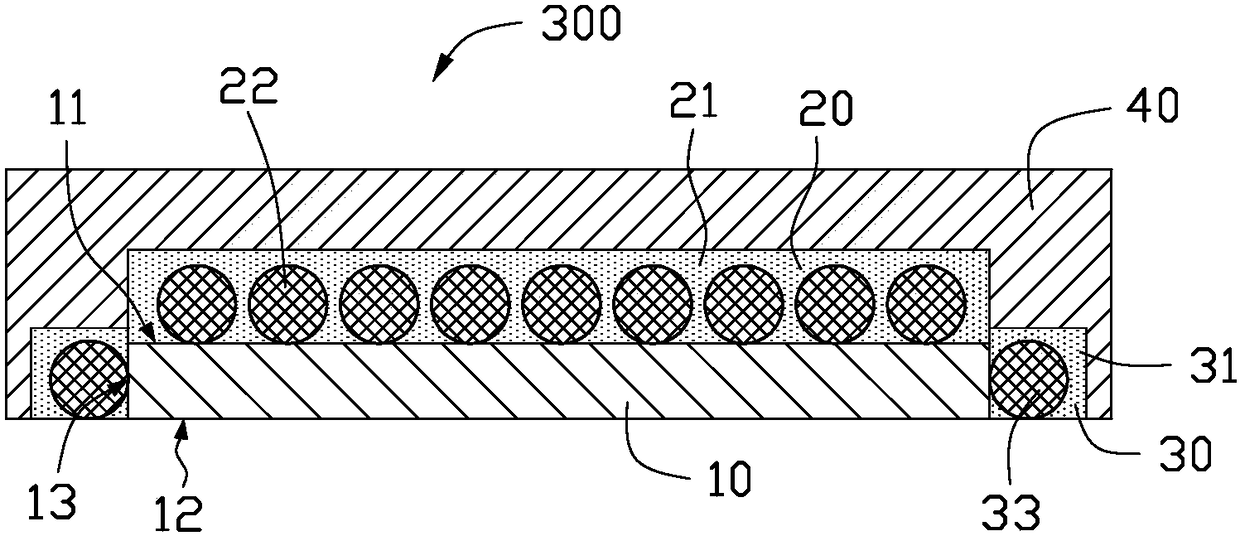

[0121] see Figure 11 and Figure 12 , the manufacturing method of the first embodiment of the light-emitting device 100 of the present invention, which includes the following steps:

[0122] Step S101, providing a plurality of light emitting chips 10, each light emitting chip 10 has an upper surface 11, a lower surface 12 and a side surface 13;

[0123] Step S102, adhering the lower surface 12 of the light-emitting chip 10 on an expansion film 50;

[0124] Step S103, uniformly dispersing microbeads 32 in the gap formed between the upper surface 11 of the light-emitting chip 10 and the adjacent light-emitting chip 10;

[0125] Step S104, removing microbeads 32 that are not adhered to the expanded membrane 50;

[0126] Step S105, applying the liquid phase containing the luminescent powders 21, 31 to the upper surface 11 of the luminescent chip 10 and the gap formed between the adjacent luminescent chips 10;

[0127] Step S106, removing the liquid so that the luminescent pow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com