Pellicle member frame and pellicle member

A pellicle and component technology, applied in the field of pellicle component frames and pellicle components, can solve the problems of size, quality, appearance damage, rough edges, and black base, and achieve the effect of excellent appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0120] Hereinafter, an Example is shown and this invention is demonstrated more concretely.

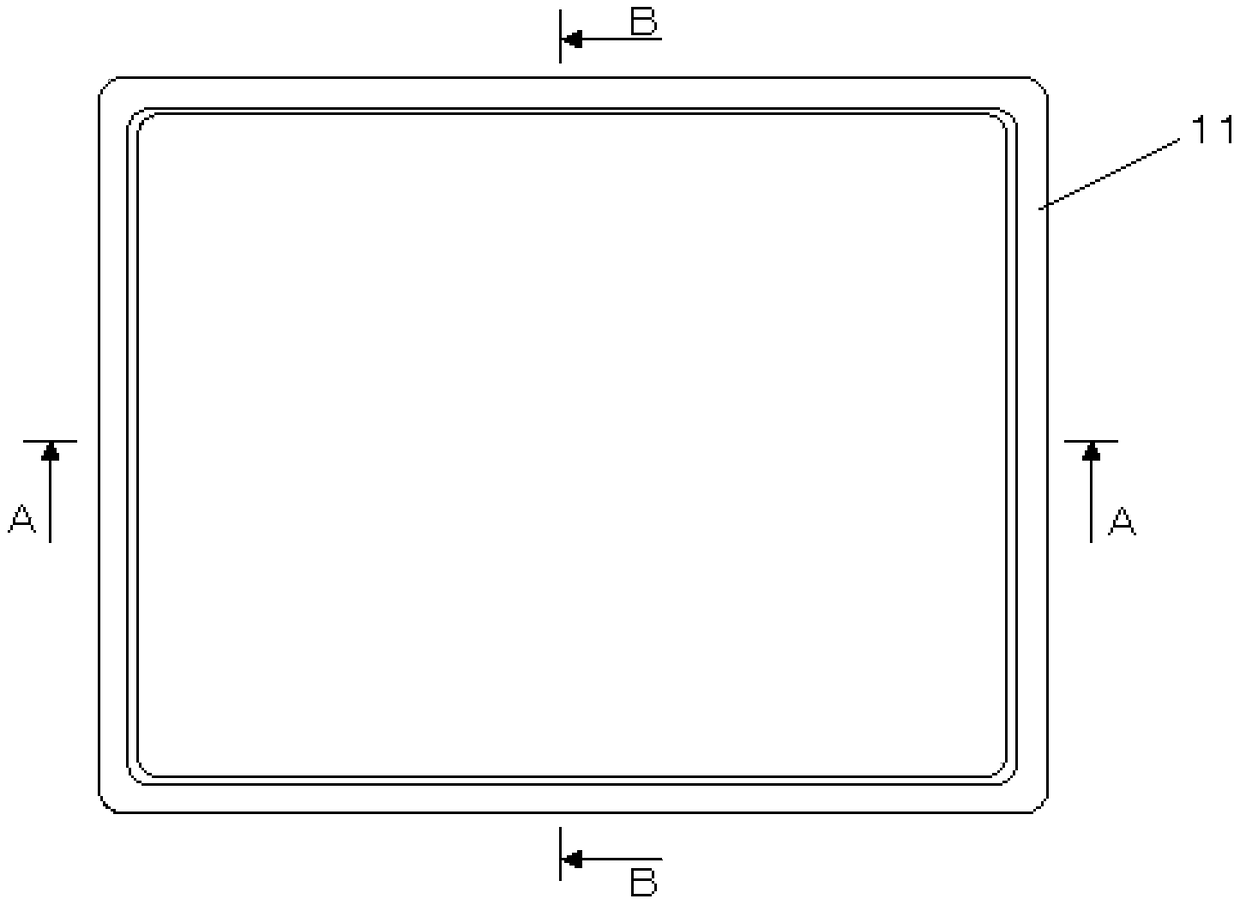

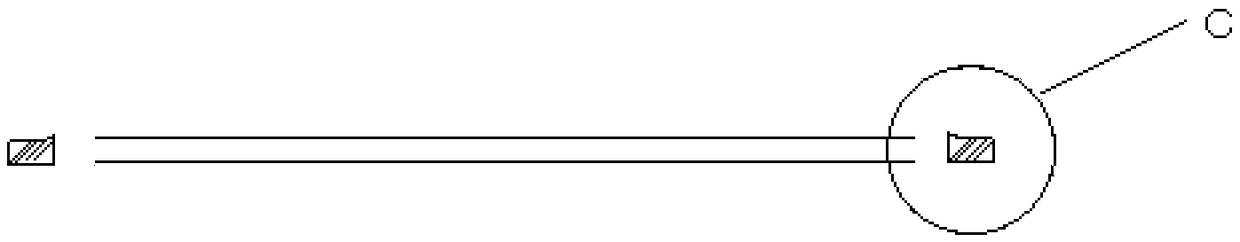

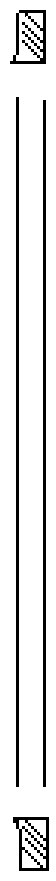

[0121] Figure 8 , Figure 9 shows the use of figure 1 , figure 2 , image 3 and Figure 4 Perspective and cross-sectional views of the membrane member fabricated from the membrane member frame shown.

[0122] The surface member frame 11 is manufactured by machining using 5000 series aluminum alloy, and is treated with a black aluminum oxide film. At this time, the dimensions of the membrane member frame 11 are: the outer dimension is 756×937.5 mm, the inner dimension is 740×925.5 mm, and the height is 5.8 mm. On the surface (film bonding surface) 12 where the film is set, an inclined surface 12a that descends from the inner edge side to the outer edge side is provided on the entire circumference, from the outer edge side terminal b of the inclined surface 12a to the edge where the film is set. The outer edge of the surface is formed with a flat surface 12b.

[0123] The wid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com