Ultra-long-life room temperature phosphorescent material and preparation method and application thereof

A room-temperature phosphorescence and ultra-long lifespan technology, applied in the field of materials science, can solve the problems of unfavorable naked eye observation, limitation of carbon quantum dot phosphorescence and delayed fluorescence performance, and achieve good acid and alkali corrosion resistance and photobleaching performance, stable and excellent phosphorescence emission The effect of high performance and productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

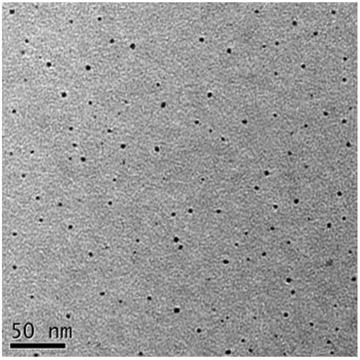

[0036] An aspect of the embodiments of the present invention provides a method for preparing an ultra-long-life room temperature phosphorescent material (also called carbon quantum dots, referred to as carbon dots), which includes:

[0037] Mix the amine compound and concentrated phosphoric acid in a solvent to form a mixed reaction solution;

[0038] The mixed reaction solution is rapidly heated to 100-200° C. for reaction, and then post-treated to obtain an ultra-long-life room temperature phosphorescent material.

[0039] In some embodiments, the volume ratio of the amine compound, concentrated phosphoric acid and solvent is 500-2000:1000-4000:4000-10000, that is, the mixed reaction solution contains 500-2000 parts by volume of the amine compound, concentrated phosphoric acid 1000-4000 parts by volume and 4000-10000 parts by volume of the solvent.

[0040] Preferably, the amine compounds include ethylenediamine, butylenediamine, hexamethylenediamine, ethylamine, cysteamine...

Embodiment 1

[0069] Example 1 The raw materials for the preparation of the ultra-long-life room temperature phosphorescent material in this example include the following materials in parts by weight: 2,000 parts of ethylenediamine, 4,000 parts of concentrated phosphoric acid, and 8,000 parts of water.

[0070] The preparation method of the ultra-long-life room temperature phosphorescent material of this embodiment includes:

[0071] After dispersing 2000 parts of ethylenediamine in 8000 parts of water, add 4000 parts of concentrated phosphoric acid to obtain a solution A dispersion;

[0072] Put the solution A dispersion in a microwave reactor for microwave heating reaction, the microwave power is 750W, the reaction temperature is 200°C, the reaction time is 2min, and then cooled to room temperature to obtain the initial product;

[0073] Add an appropriate amount of water to dissolve the initial product; use sodium hydroxide solution to neutralize and adjust the pH to 10;

[0074] After ...

Embodiment 2

[0077] Example 2 The raw materials for the preparation of the ultra-long-life room temperature phosphorescent material in this example include the following materials in parts by weight: 500 parts of ethylenediamine, 4000 parts of concentrated phosphoric acid, and 10000 parts of water.

[0078] The preparation method of the ultra-long-life room temperature phosphorescent material of this embodiment includes:

[0079] After dispersing 500 parts of ethylenediamine in 10000 parts of water, add 4000 parts of concentrated phosphoric acid to obtain a solution A dispersion;

[0080] Put the A dispersion in a microwave reactor for microwave heating reaction, the microwave power is 500W, the reaction temperature is 100°C, the reaction time is 30min, and then cooled to room temperature to obtain the initial product;

[0081] Add an appropriate amount of water to dissolve the initial product; use sodium hydroxide solution to neutralize and adjust the pH to 10;

[0082] After the obtaine...

PUM

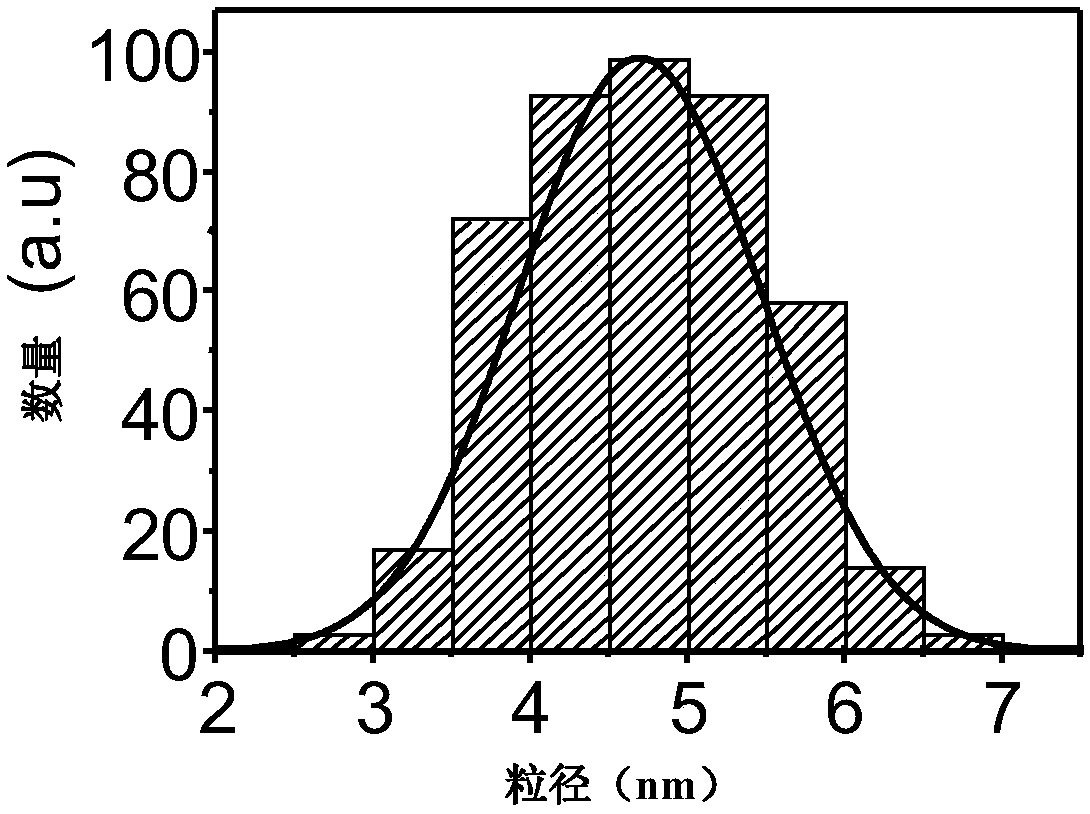

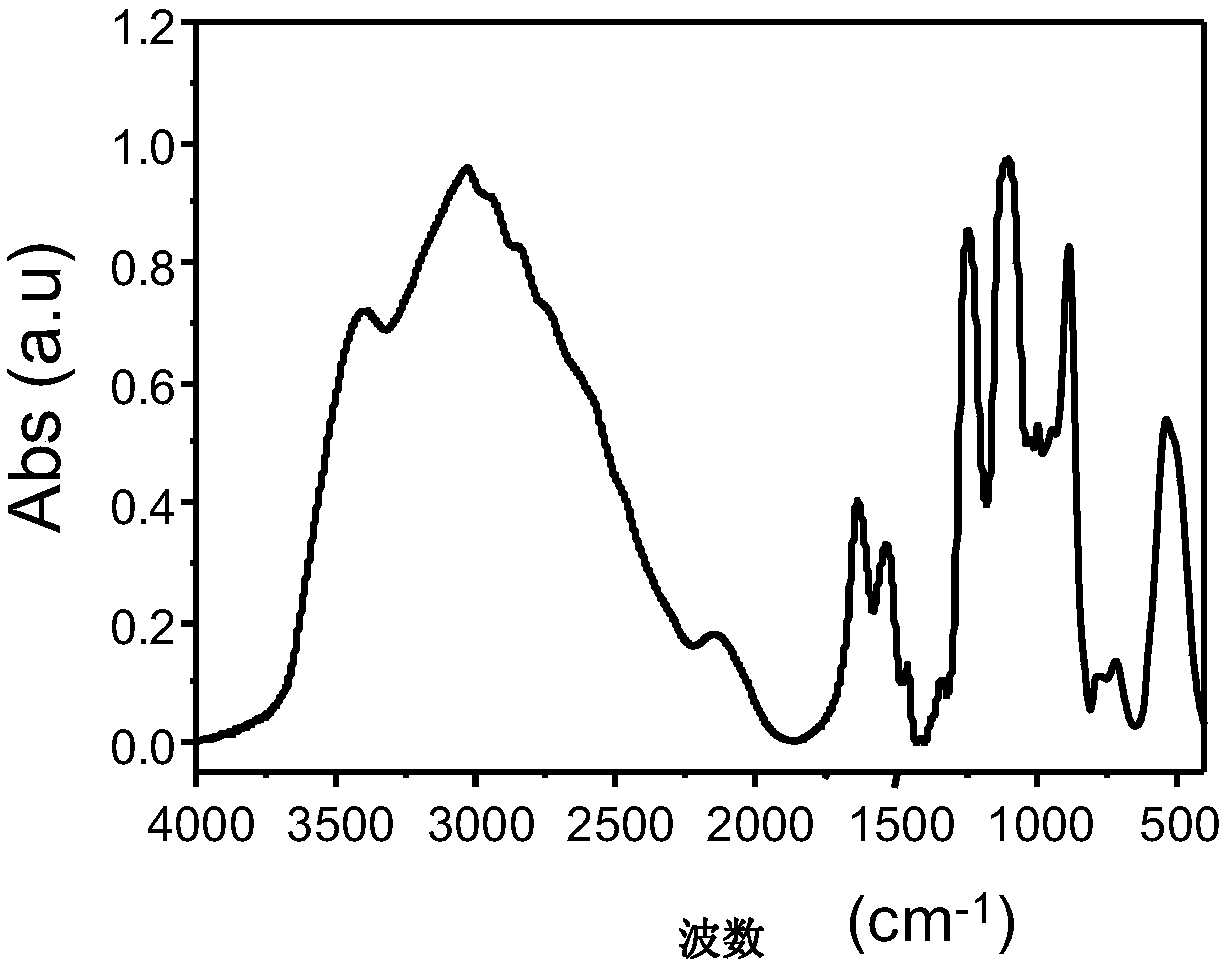

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com