Lithium battery electrolyte-proof flame-retardant adhesive, preparation method thereof, and adhesive tape

A technology of electrolyte and flame retardant glue, which is applied in the manufacture of electrolyte batteries, adhesives, adhesive additives, etc., can solve the problems of poor electrolyte resistance and cannot meet application requirements, and achieve the effect of enhancing flame retardant performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

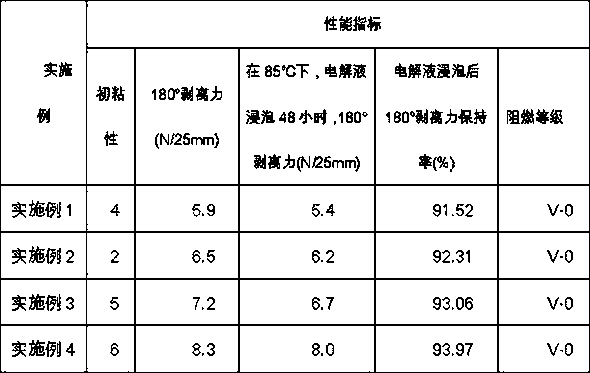

Embodiment 1

[0027] Embodiment 1, which is an electrolyte-resistant flame-retardant adhesive and an electrolyte-resistant flame-retardant adhesive tape for lithium batteries, is prepared by the following steps. Step 1 synthesizes an electrolyte-resistant flame-retardant adhesive. 60 parts of stearyl acrylate (SA), 6 parts of 4-methacryloxyethyl trimellitic anhydride (4-META), 2 parts of acrylonitrile (AN), 5 parts of diethyl vinyl phosphate , 0.02 parts of free radical initiator tert-butyl peroxymaleate (TBMA), 0.12 parts of ferric chloride, 0.25 parts of triphenylphosphine and 100 parts of toluene are mixed, and nitrogen deoxygenation is performed for 60 minutes , the temperature was controlled at 90°C, and the reverse atom transfer radical polymerization (R-ARTP) polymerization reaction was carried out under the protection of nitrogen for 8 hours. to 30°C, add 6 parts of epoxidized polybutadiene (epoxy value is 0.54 mol / 100g, number average molecular weight is 2066) and 0.1 part of curin...

Embodiment 2

[0030] Embodiment 2, which is an electrolyte-resistant flame-retardant adhesive and an electrolyte-resistant flame-retardant adhesive tape for lithium batteries, is prepared by the following steps. Step 1 synthesizes an electrolyte-resistant flame-retardant adhesive. 50 parts of stearyl acrylate (SA), 3 parts of 4-methacryloxyethyl trimellitic anhydride (4-META), 1 part of acrylonitrile (AN), 5 parts of vinyl dimethyl phosphate , 0.07 parts of free radical initiator tert-butyl peroxymaleate (TBMA), 0.1 part of ferric chloride, 0.2 parts of triphenylphosphine and 100 parts of ethyl acetate were mixed, and nitrogen deoxygenation was carried out for 50 Minutes later, the temperature was controlled at 80°C, and the reverse atom transfer radical polymerization (R-ARTP) polymerization reaction was carried out under nitrogen protection for 15 hours. The number average molecular weight (Mn) was controlled to 254400, and the molecular weight polydispersity coefficient was controlled to ...

Embodiment 3

[0033] Embodiment 3, which is an electrolyte-resistant flame-retardant adhesive and an electrolyte-resistant flame-retardant adhesive tape for lithium batteries, is prepared by the following steps. Step 1 synthesizes an electrolyte-resistant flame-retardant adhesive. 45 parts of stearyl acrylate (SA), 3 parts of 4-methacryloxyethyl trimellitic anhydride (4-META), 1 part of acrylonitrile (AN), 6 parts of diethyl vinyl phosphate , 0.1 part of free radical initiator tert-butyl peroxymaleate (TBMA), 0.2 part of ferric chloride, 0.4 part of triphenylphosphine and 80 parts of ethyl acetate were mixed, and nitrogen deoxygenation was carried out for 80 Minutes later, the temperature was controlled at 85°C, and the reverse atom transfer radical polymerization (R-ARTP) polymerization reaction was carried out under the protection of nitrogen for 10 hours. The temperature is lowered to 20°C, and then 8 parts of epoxidized polybutadiene (epoxy value is 0.54 mol / 100g, number average molecul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com