Fiber-reinforced silicon dioxide heat-insulating ceramic material and preparation method and application thereof

A silica and fiber reinforced technology is applied in the field of thermal insulation ceramic materials, which can solve the problems of unsuitable weight reduction requirements for aircraft, reduced porosity of composite materials, poor thermal insulation effect, etc., and achieves good thermal insulation effect. The effect of sufficient bonding and high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

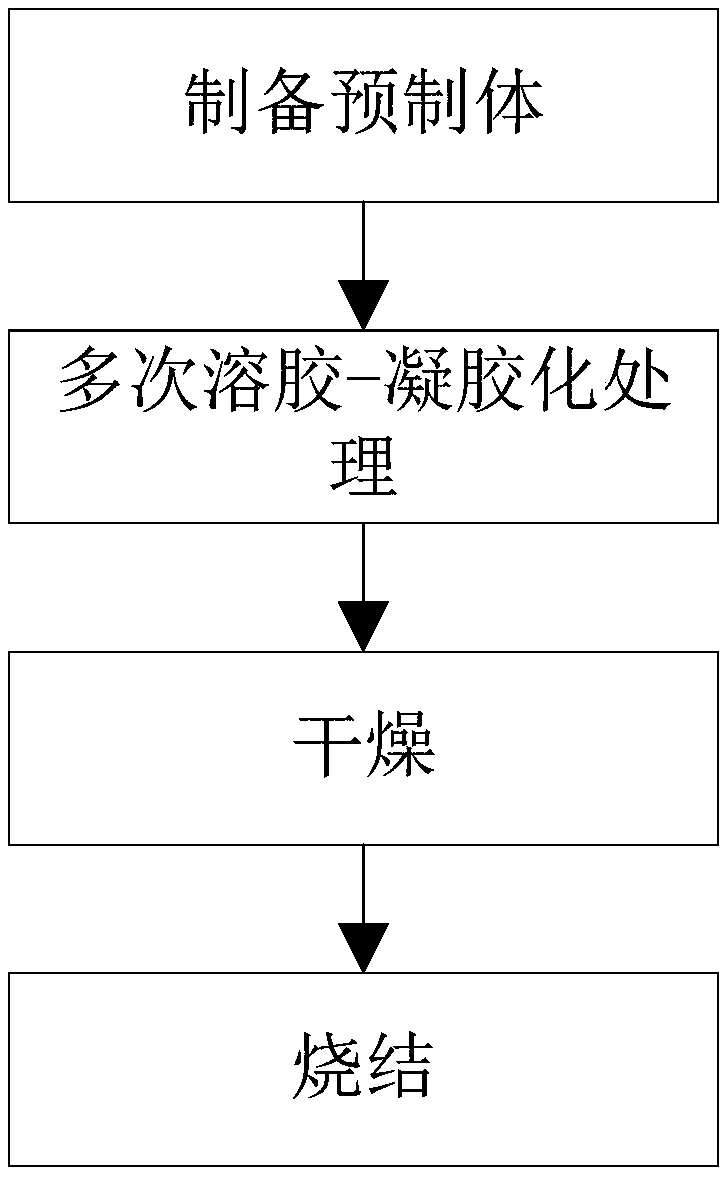

[0038] The invention provides a preparation method of a fiber-reinforced silica heat-insulating ceramic material, such as figure 1 Shown, described preparation method comprises:

[0039] (1) Preparation of preform

[0040] The preform (that is, the fiber preform) can be made by processing fibers (such as fiber yarn) through weaving or needle punching. In order to ensure the effect of impregnation, the processed preform can also be pretreated to remove the wetting agent, so as to obtain a preform for impregnation with good surface wettability. The pretreatment can be completed with an organic solvent, and the organic solvent can use existing products, such as acetone, ethanol, chloroform, etc., which are not listed in the present invention.

[0041] The present invention preferably adopts a preform with a fiber volume content of 20-40%, for example, 20%, 21%, 22%, 23%, 24%, 25%, 26%, 27%, 28%, 29%, 30% , 31%, 32%, 33%, 34%, 35%, 36%, 37%, 38%, 39%, 40%. For the preform, the...

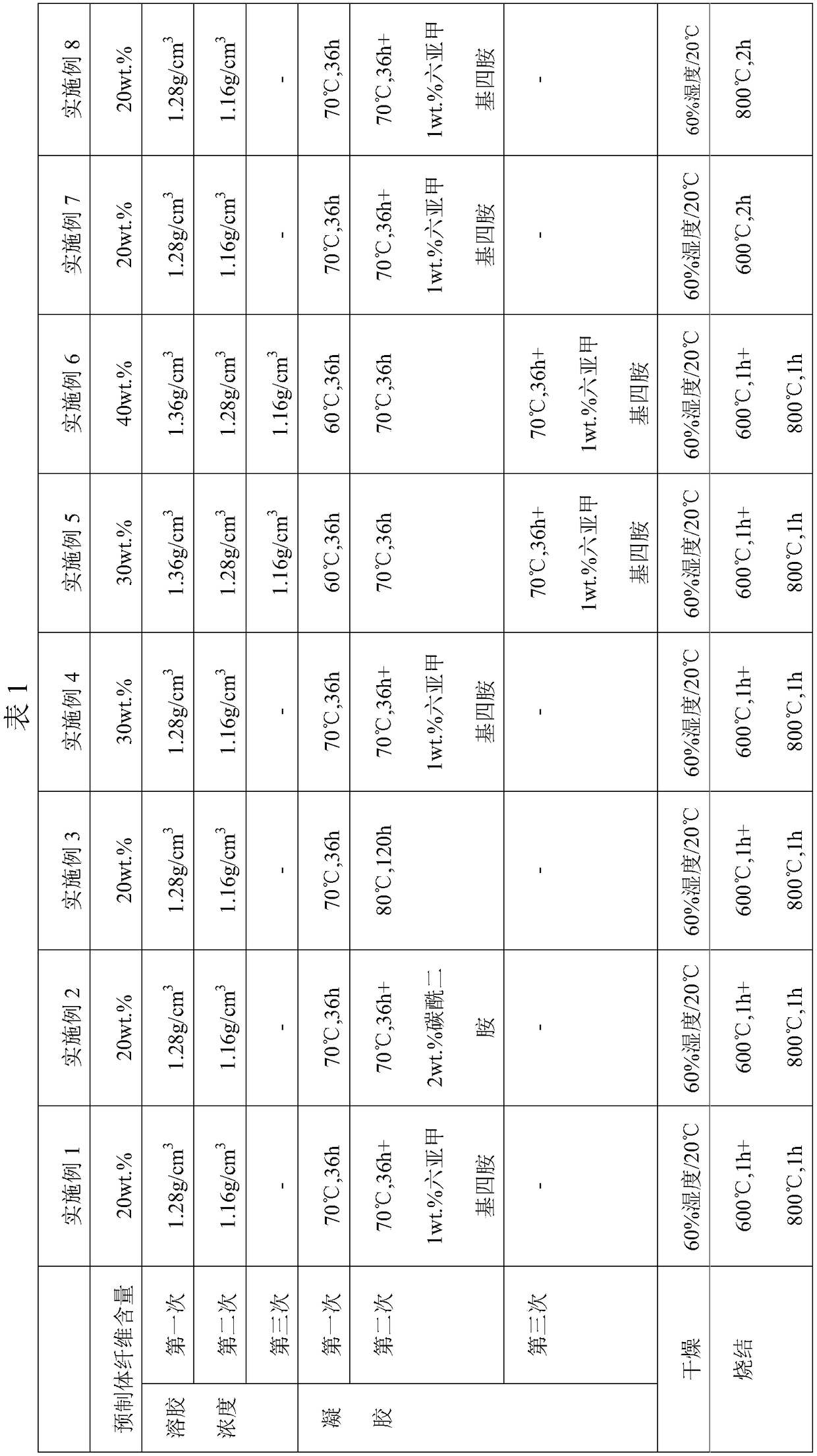

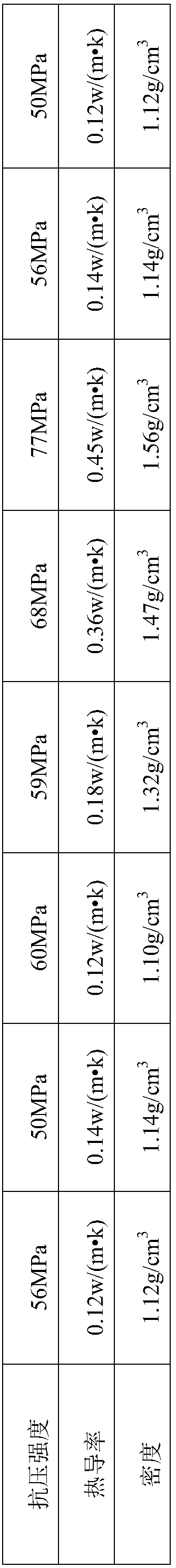

Embodiment 1

[0063] The quartz fiber is processed into a preform with a fiber volume content of 20% by mechanical needle punching, and the sizing agent is removed by an organic solvent (acetone is used in this example) to obtain a preform for impregnation with good surface wettability, which is used for Subsequent impregnation step.

[0064] The density is 1.28g / cm 3 The preform is impregnated with silica sol by vacuum / pressure impregnation method, the preform is filled with filler and densified, and then the sol-gel reaction is carried out, so that the cross-linking between the gel and the preform is gradually integrated, and the control of the first The secondary sol-gel reaction temperature is 70°C, the time is 36h, no gelling aid is added; the density is 1.16g / cm 3 The preform is impregnated with silica sol by vacuum / pressure impregnation method, and then sol-gel reaction is carried out, the temperature of the second sol-gel reaction is controlled at 90°C, the time is 36h, and the add...

Embodiment 2

[0068] The quartz fiber is processed into a preform with a fiber volume content of 20% by mechanical needle punching, and the sizing agent is removed by an organic solvent (acetone is used in this example) to obtain a preform for impregnation with good surface wettability, which is used for Subsequent impregnation step.

[0069] The density is 1.28g / cm 3 The preform is impregnated with silica sol by vacuum / pressure impregnation method, the preform is filled with filler and densified, and then the sol-gel reaction is carried out, so that the cross-linking between the gel and the preform is gradually integrated, and the control of the first The secondary sol-gel reaction temperature is 70°C, the time is 36h, no gelling aid is added; the density is 1.16g / cm 3 The preform is impregnated with silica sol by vacuum / pressure impregnation method, and then the sol-gel reaction is carried out. The temperature of the second sol-gel reaction is controlled at 90°C, the time is 36h, and 2wt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com