Combined type centrifugal sludge dewatering machine

A sludge dewatering machine and centrifugal dewatering technology, applied in water/sludge/sewage treatment, sludge treatment, dewatering/drying/concentrated sludge treatment, etc., can solve the problems of poor dewatering effect and high energy consumption, etc. To achieve the effect of good use value, good dehydration effect, simple and ingenious structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

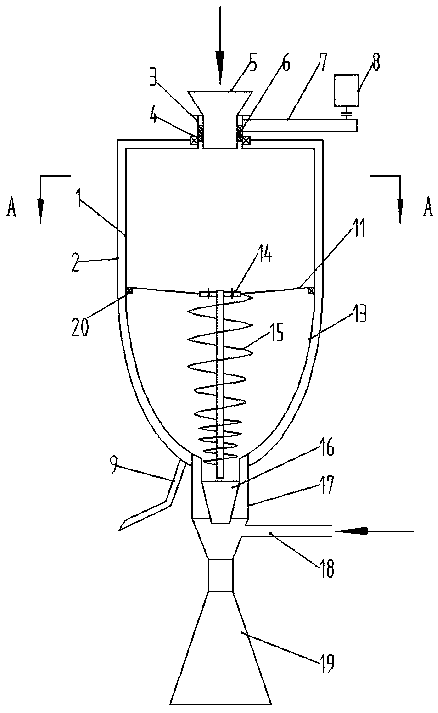

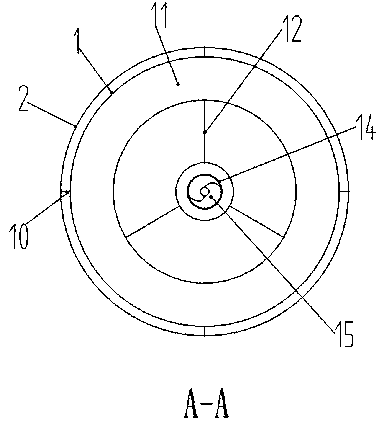

[0036] Such as figure 1 with figure 2As shown, a composite centrifugal sludge dewatering machine includes a centrifugal dehydration mechanism, a screw stack dewatering mechanism and a heating device; the centrifugal dehydration mechanism and the screw stack dehydrator form an upper and lower structure for installation and connection, and the centrifugal dehydration mechanism includes a centrifugal cylinder 1, The drive shaft sleeve 3 and the drive motor 8, the snail stacking dehydration mechanism includes a snail stacking dehydration cylinder 13 and a snail stacking auger 15; A driving bushing 3 is provided at the place, and the driving bushing 3 is connected with the driving motor 8. The driving bushing 3 is set on the outer wall of a mud feeding bucket 5, and can enter the mud bucket 5 relatively under the action of the driving motor 8. Rotation; the bottom of the centrifuge cylinder 1 is an open structure connected with the snail dehydration cylinder 13, and the end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com