Rice conveying device achieving flexible and convenient loading

A technology for conveying devices and rice, which is applied in the direction of cleaning devices, conveyors, conveyor objects, etc., can solve the problems of low efficiency of conveyor belts, lack of conveyor belt cleaning components, and rice sliding, etc., to achieve a scientific and novel transmission process and flexible loading Convenience and the effect of speeding up the work progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical scheme of a flexible and convenient rice conveying device provided by the present invention will be further described below in conjunction with the accompanying drawings, so that those skilled in the art can better understand the present invention and implement it.

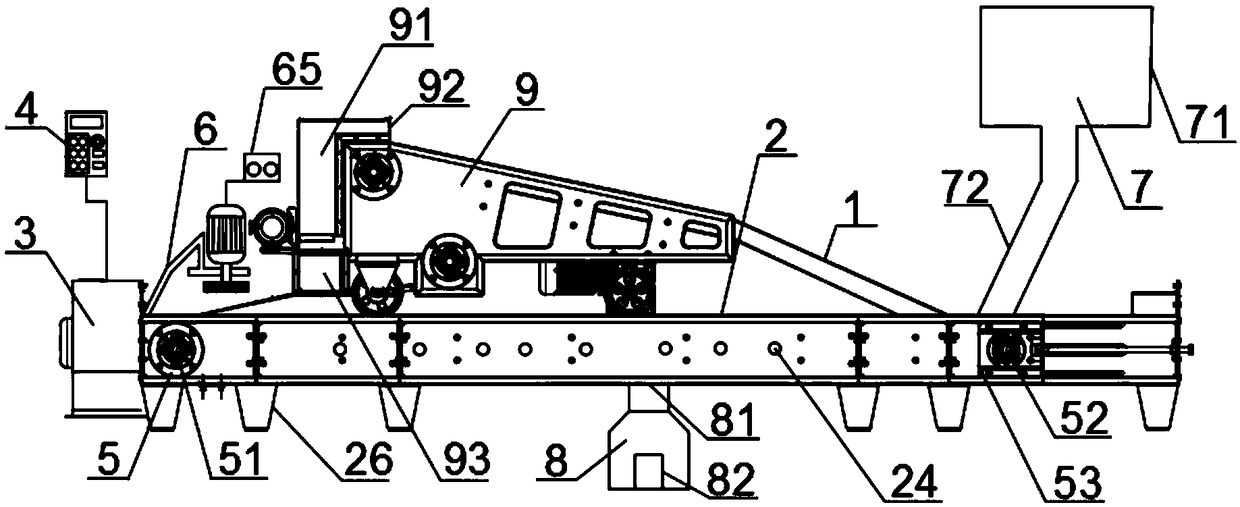

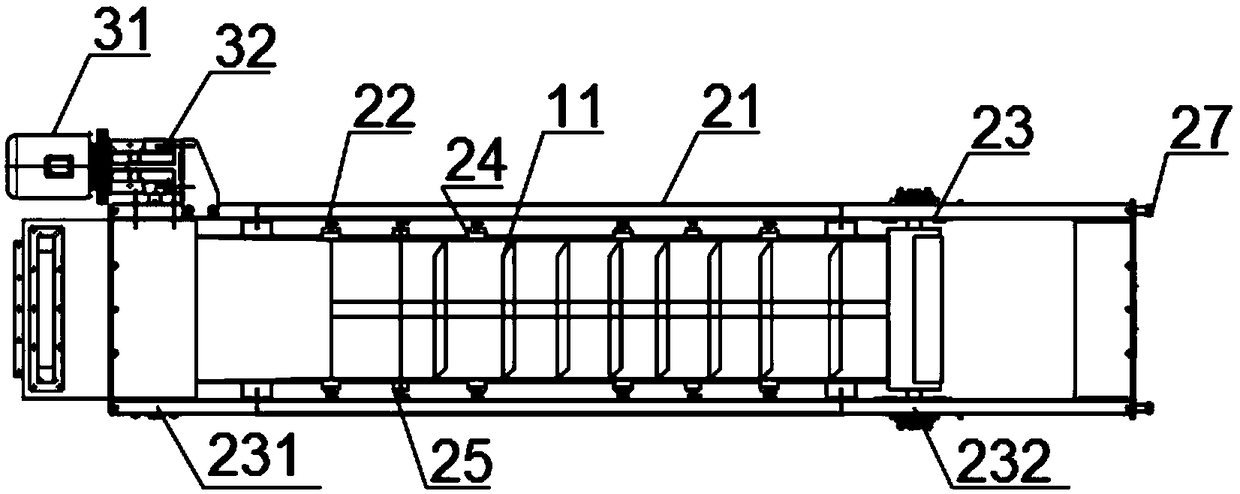

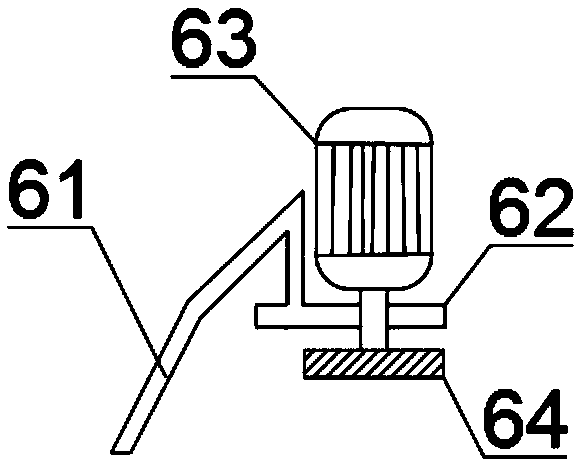

[0026] see figure 1 , figure 2 , image 3 , Figure 4 The present invention provides a flexible and convenient rice conveying device, comprising a rice conveying belt 1, a rice conveying support frame 2, a rice conveying motor unit 3, a rice conveying motor frequency converter 4, a conveying roller group 5, a conveyor belt cleaning assembly 6, Rice supply bin 7, rice bin 8, mobile trolley 9, the outlet of rice at the lower end of rice supply bin 7 is fixed on the front end of rice conveyor belt 1, rice bin 8 is provided with multiple, and multiple rice bins 8 are fixedly installed on the rice support at the same distance Frame 2 left and right sides, rice bin 8 comprises rice bin inlet 81,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com