Novel solid wood decorative board processing method

A processing method and technology of decorative boards, applied in wood processing equipment, decorative arts, special decorative structures, etc., can solve the problems of waste of wood resources, waste of energy, pollution of the environment, etc., to achieve environmental protection, reduce the amount of planing, reduce pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

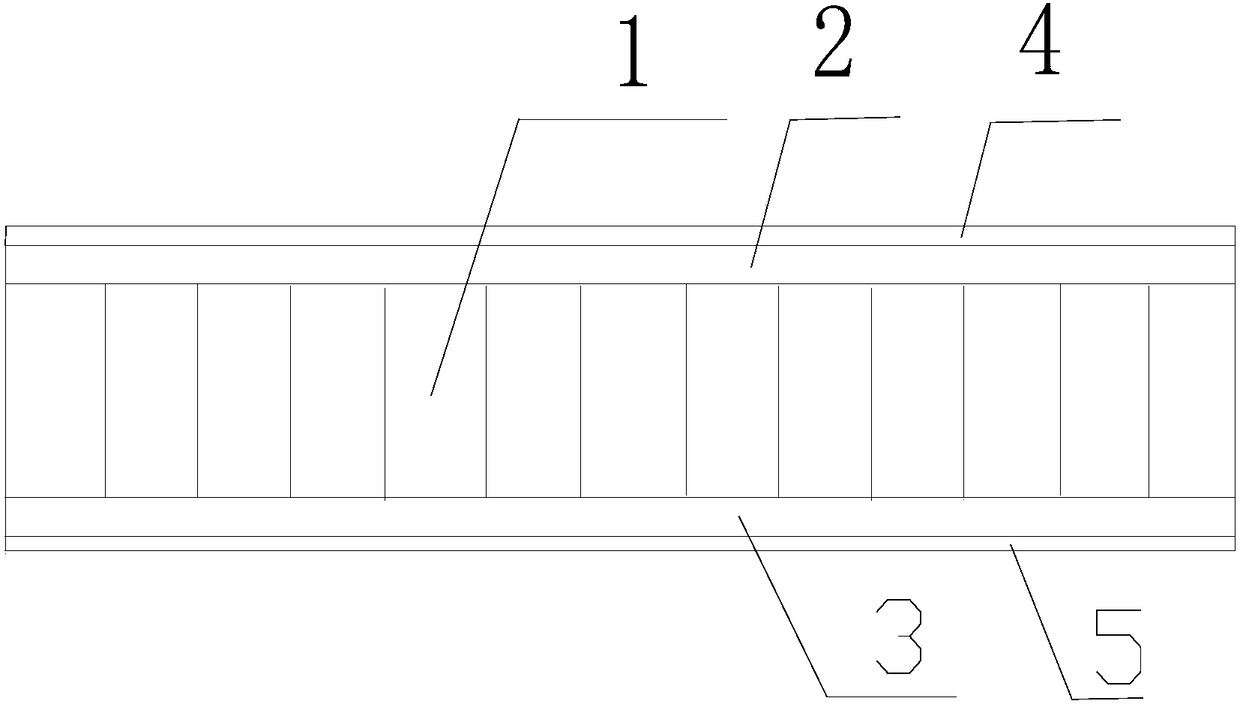

[0012] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0013] Such as figure 1 As shown, a novel processing method of a solid wood decorative board of the present invention includes a middle core board 1, an upper rib veneer 2, a lower rib veneer 3, an upper cortex 4 and a lower cortex 5. First cut the economical forest raw material into small wooden strips with a thickness of 2 to 6mm, then coat the small wooden strips with glue, arrange the small wooden strips vertically and vertically in turn, press them into the middle core board 1 through the machine side, and then the middle core board 1 The upper and lower surfaces are coated with an adhesive layer, and then the upper skin veneer 2 and the lower rib skin veneer 3 are respectively pasted on the upper and lower surfaces of the middle core board 1 under high temperature and high pressure conditions, and finally the upper skin layer 4 and the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com