Aluminum alloy CMT arc welding rotary table jig

A technology of aluminum alloy and aluminum alloy plate, which is applied in welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of high temperature of positioning and pressing blocks, affecting the quality of arc welding, and great difficulty, so as to achieve reduction, correction, deformation or repair process, ensure continuous production, reduce or effect of thermal deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

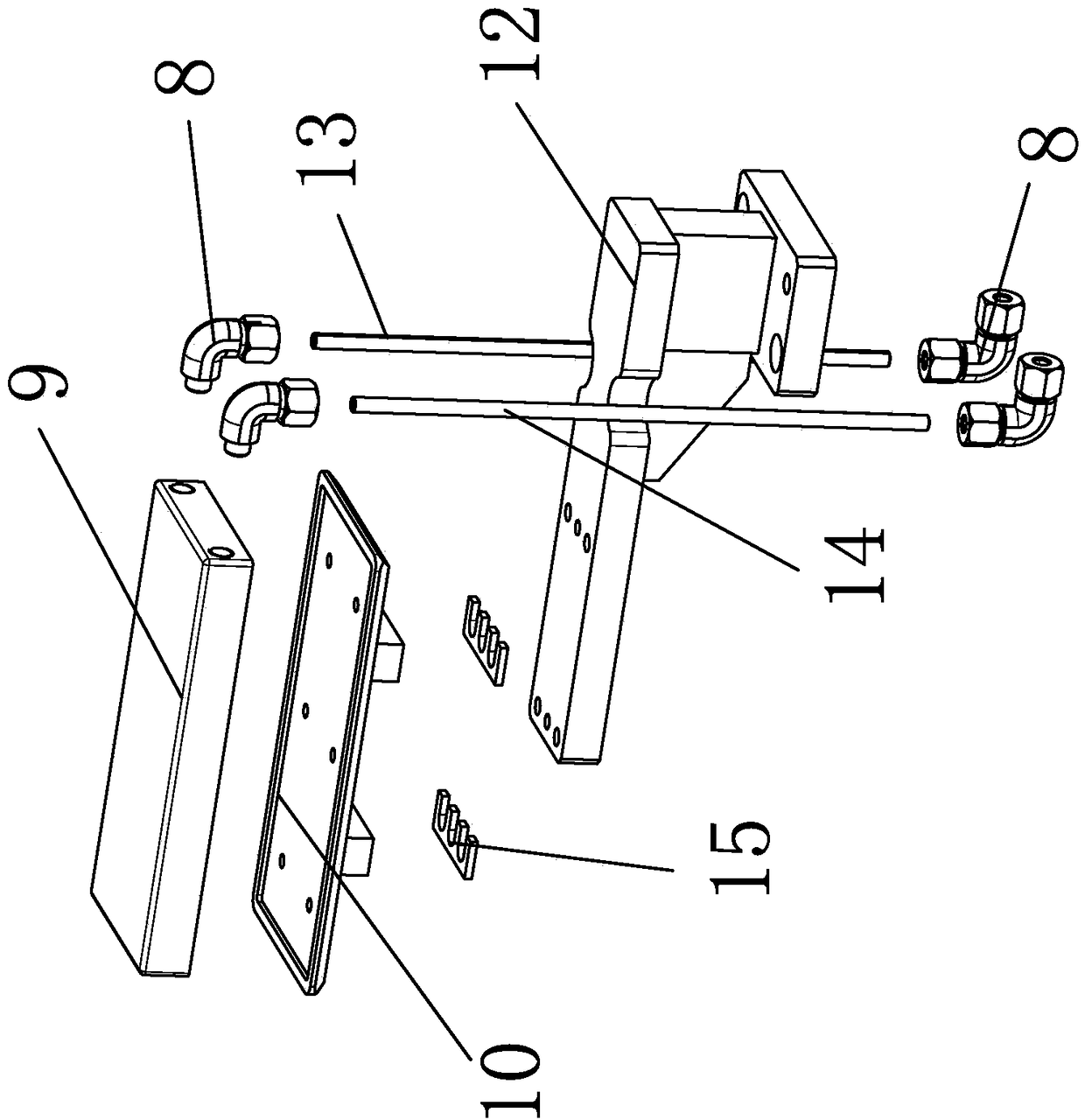

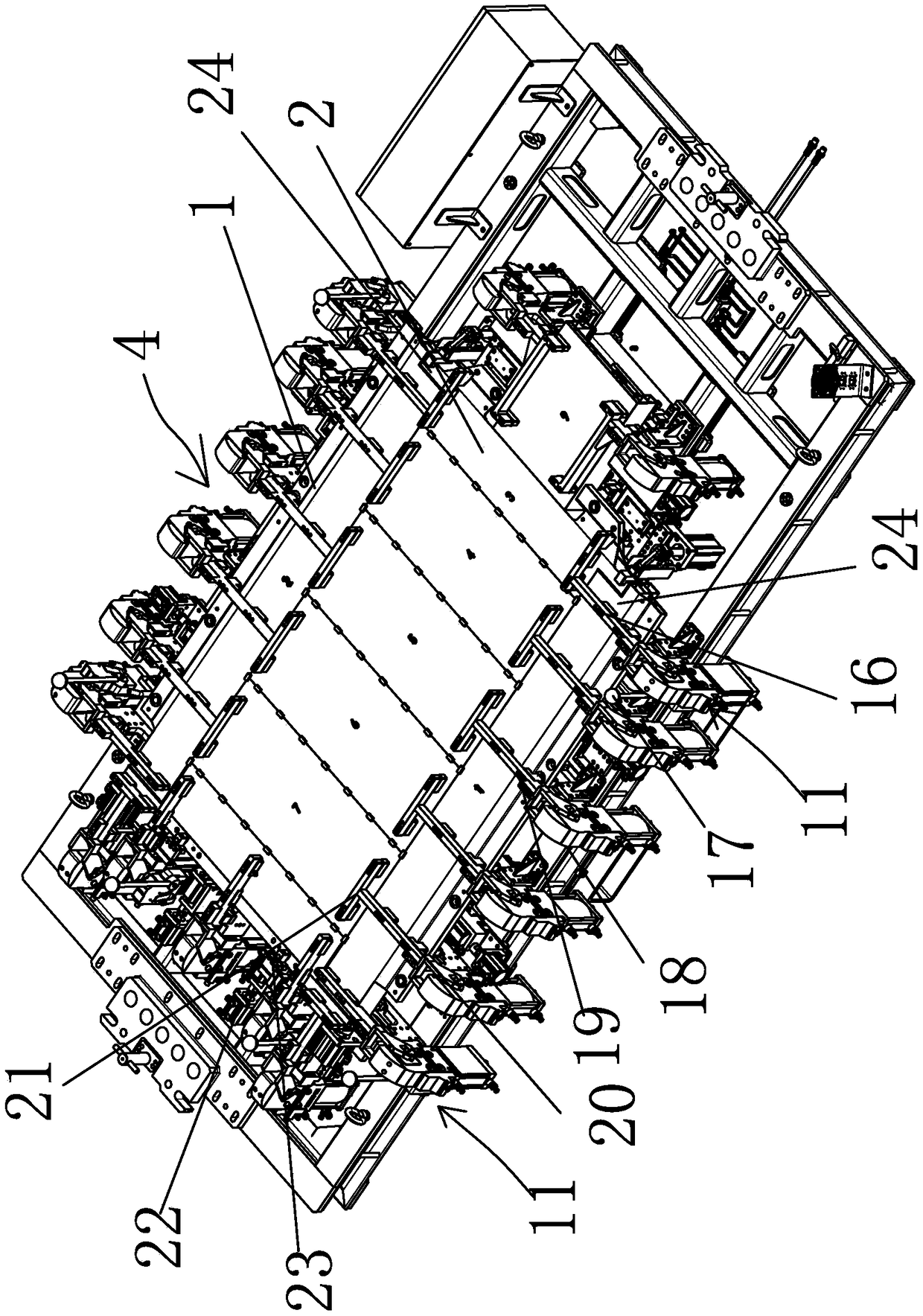

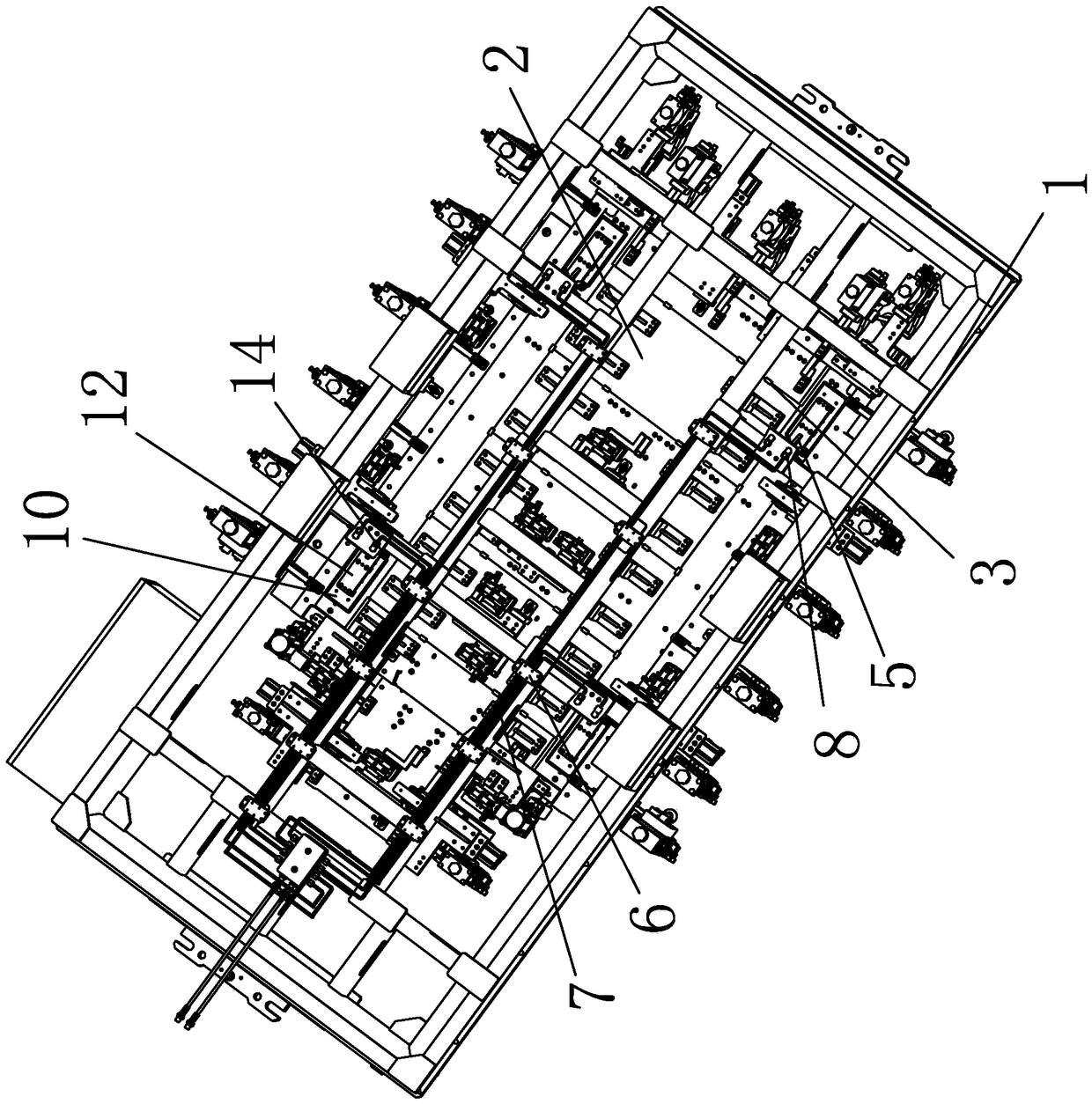

[0020] In the figure, fixture main body 1; aluminum alloy frame plate 2; arc welding bead 3; clamp mechanism 4; support surface water cooling plate mechanism 5; liquid temperature controller 6; ; supporting surface water cooling plate 9; lower sealing plate 10; pre-pressing clamp assembly 11; fixed bracket 12; input copper tube 13; output copper tube 14; gap adjustment gasket 15; ; Clamp cylinder 18; Locking pressure piece 19; Straight locking part 20; Horizontal locking part 21;

[0021] Such as figure 1 and figure 2 As shown, the aluminum alloy CMT arc welding turntable fixture includes a fixture main body 1, on which there are multiple aluminum alloy frame plates 2, and multiple aluminum alloy plate frame plates are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com