Semi-automatic laminator and laminating method

A film laminating machine, semi-automatic technology, applied in the direction of battery assembly, sustainable manufacturing/processing, climate sustainability, etc., can solve the problems of many bubbles, cannot meet the needs of mass production of lithium batteries, low efficiency, etc., and achieve film consistency Good, high film sticking efficiency, simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

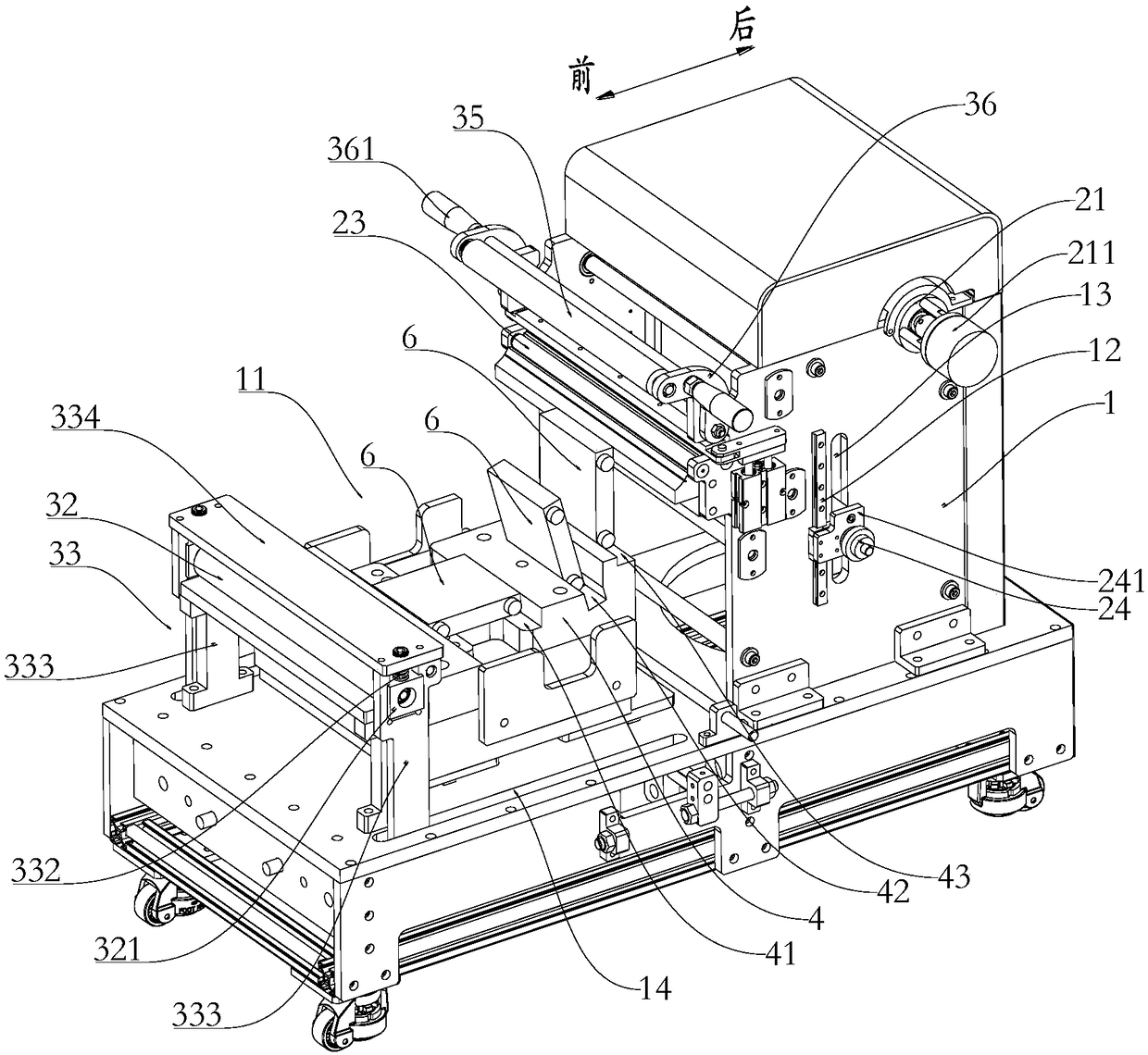

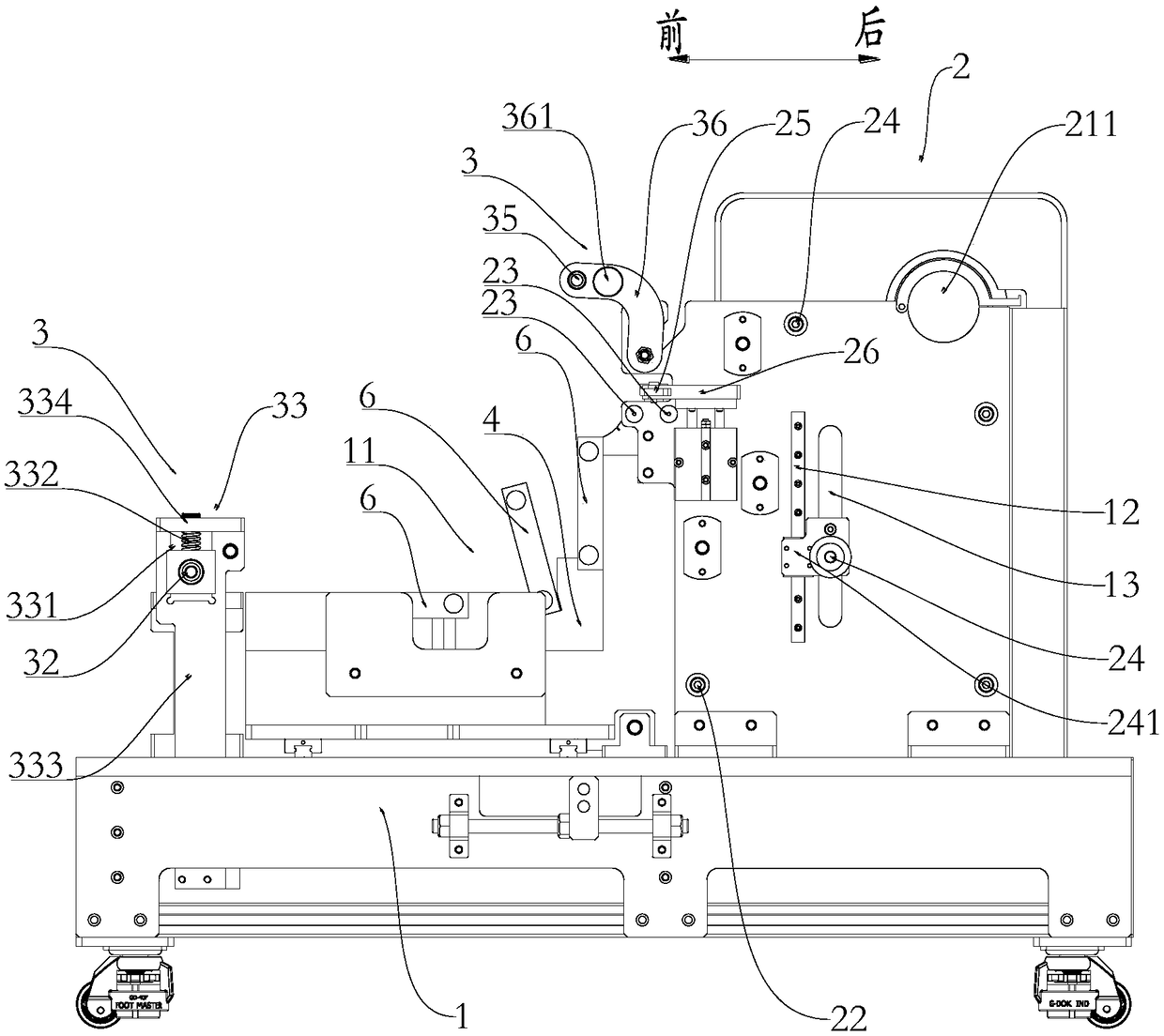

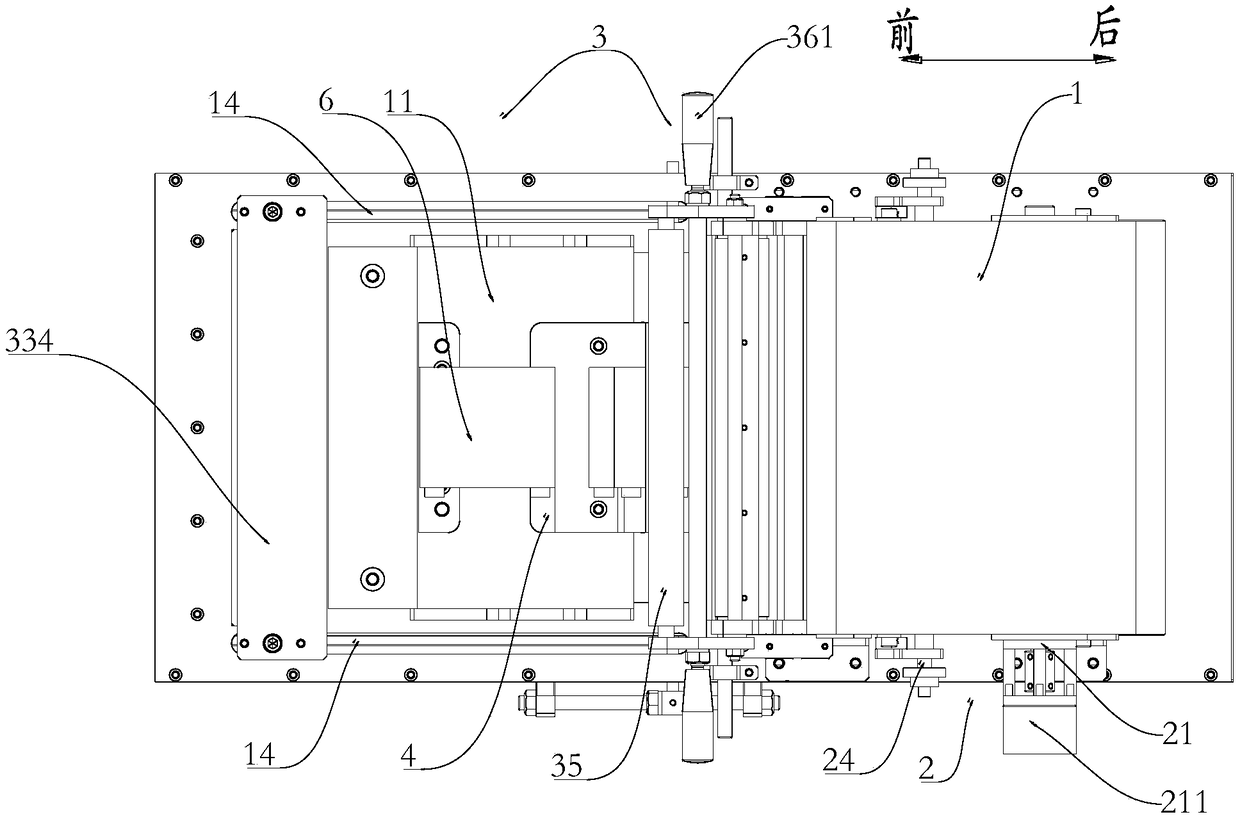

[0044] Such as Figure 1-Figure 4 As shown, a semi-automatic film laminating machine of this embodiment includes a frame 1, a film feeding device 2 and a film pressing device 3, and the film feeding device 2 and the film pressing device 3 can be detachably mounted on the frame 1 , the frame 1 between the laminating device 3 and the film feeding device 2 is reserved a coating area 11 for installing the tooling fixture 4, and the film feeding device 2 transports the packaging film 5 forward to the Above the coating area 11 and through the film pressing device 3, the packaging film is pressed and fixed on the outer side wall of the article to be packaged in the jig 4.

[0045] Wherein, the item to be packaged in this embodiment is a cubic structure of any size, such as a new energy battery, a packaging box, a tool box, and the like. In this embodiment, when describing the structure and principle of the semi-automatic film laminating machine, the battery 6 used in the battery pac...

Embodiment 2

[0067] Such as Figure 4 As shown, a method of using the above-mentioned semi-automatic film sticking machine in this embodiment to carry out film sticking comprises the following steps:

[0068] S1, install the tooling fixture in the coating area, and place the items to be packaged in the chute of the tooling fixture obliquely;

[0069] S2, open the film feeding device, the film feeding device sends the packaging film to the film outlet, then manually pull the packaging film, attach the end of the packaging film to the first edge of the upper end of the article to be packaged, and smooth it;

[0070] S3, then put the item to be packaged on the intermediate platform of the tooling fixture, manually pull the packaging film forward and downward, so that the item to be packaged lies flat on the intermediate platform, and the packaging film above the item to be packaged is inclined at Above the items to be packaged; (At this time, in order to avoid the backflow of the packaging f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com