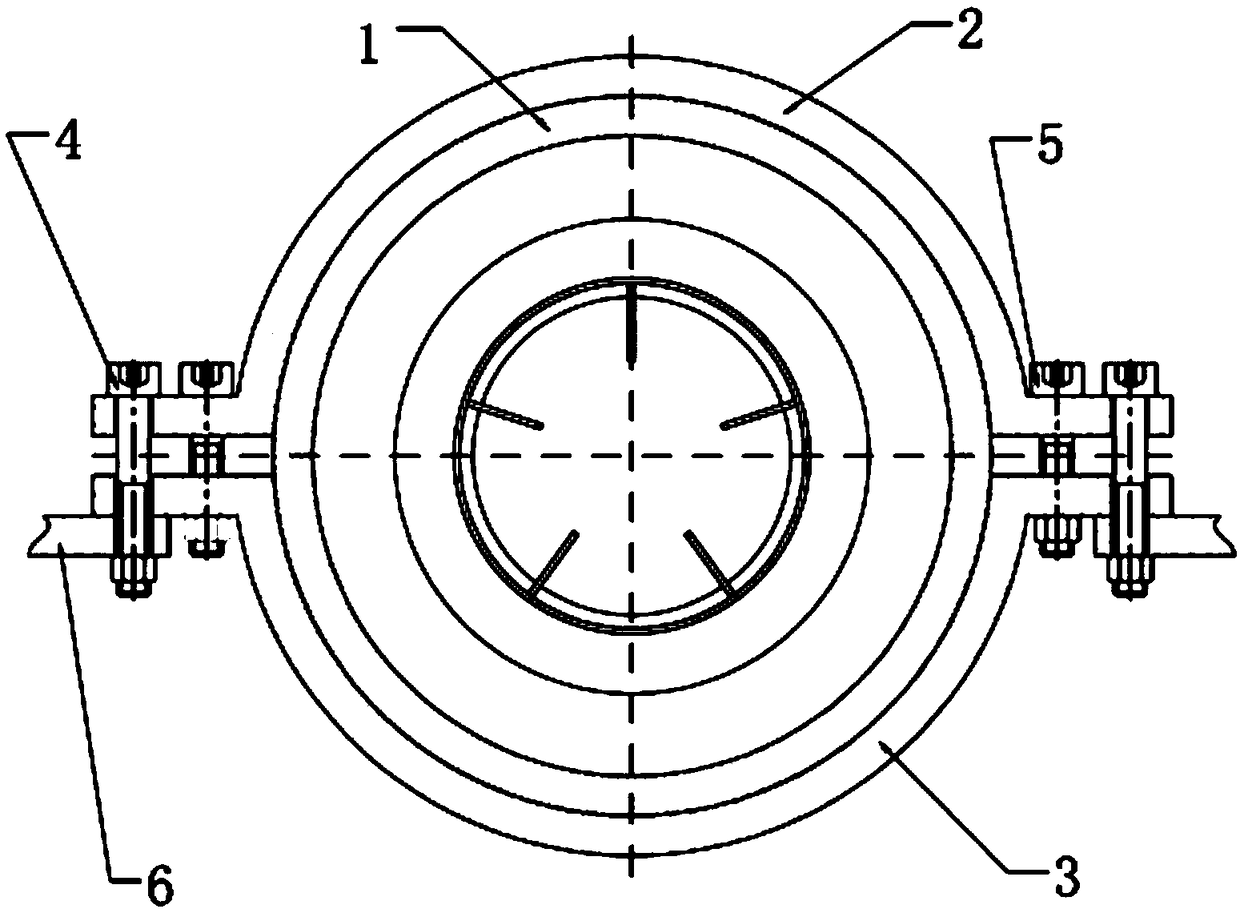

Design method of double-sided arcuate band clearance for micro-turbojet engines

A technology of a turbojet engine and a design method, which is applied in the directions of calculation, special data processing applications, instruments, etc., can solve the problem that the tightening force of the strap cannot be used with the tightening torque of the fixed bolt, the restraint force of the strap on the engine is difficult to control, and the upper and lower straps cannot be controlled. Inability to close and other problems to achieve the effect of improving material utilization, achieving lightweight, and improving inclusiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0172] The relevant parameters involved in a certain type of micro-turbojet engine band are as follows:

[0173] Engine mass: m=10kg;

[0174] Axial shock acceleration: a=2000m / s 2 (200g);

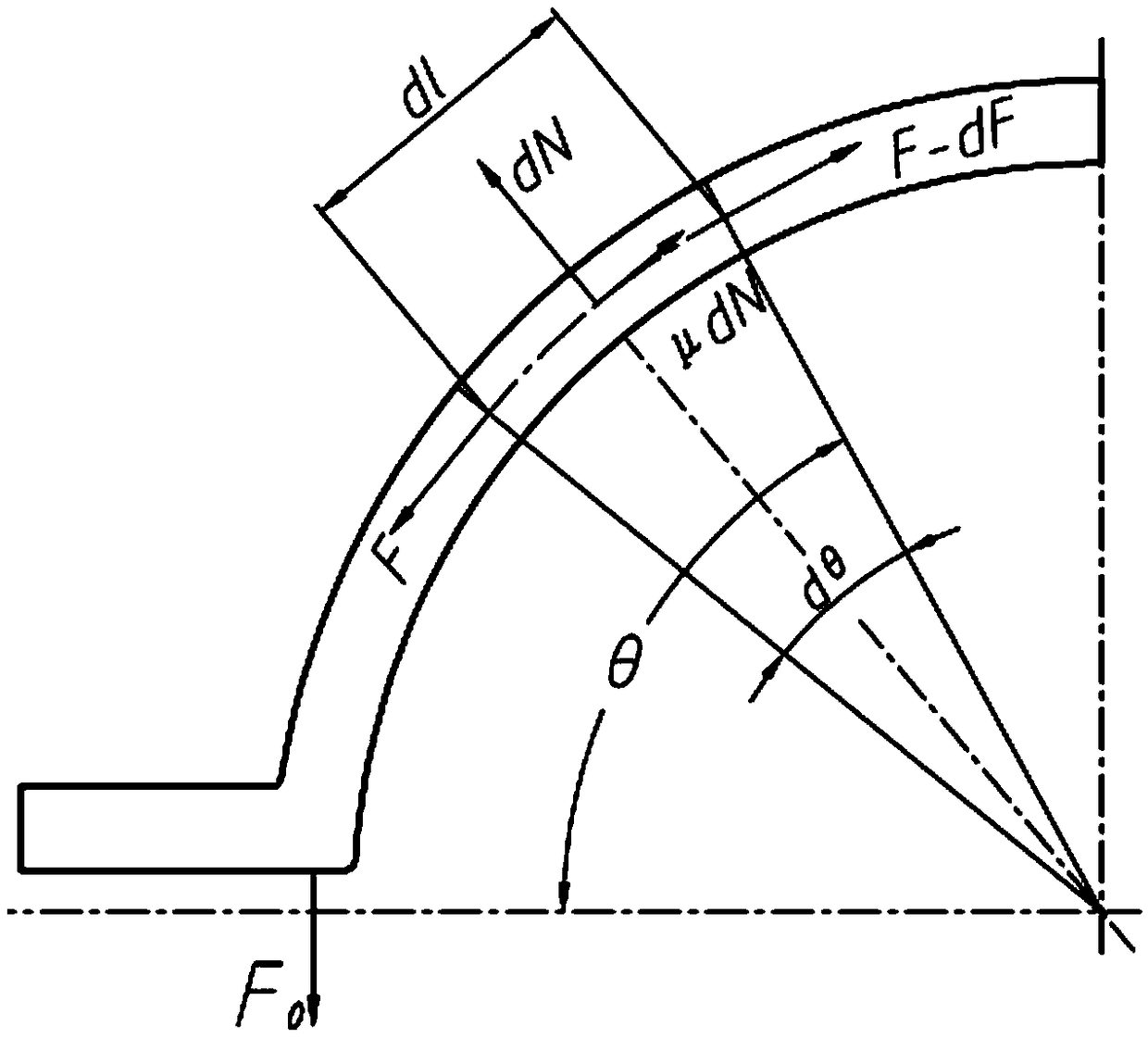

[0175] Friction coefficient: μ=0.08;

[0176] Shell outer diameter: R=102;

[0177] Number of strap groups: n=2;

[0178] Material elastic modulus: E=196GPa;

[0179] Material yield limit: σ s =198MPa;

[0180] Band cross-sectional area: S=Bt=1×10 -3 ×15×10 -3 =1.5×10 -5 m 2 ;

[0181] Band inner diameter:

[0182] Shell outer diameter:

[0183] The expression of the relationship between the constraint force required by the engine and the theoretical minimum clearance of the strap is:

[0184]

[0185] The input data are:

[0186]

[0187] The formula for calculating the theoretical maximum clearance of the hoop is:

[0188]

[0189] Check the uniaxial tensile stress-strain curve of 1Cr18Ni9Ti (attached Figure 5 ) shows that 1.5σ s The corresponding strain v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com