A material level measuring device and a material conveying system

A material level measurement and drive system technology, used in measurement devices, measurement of ultrasonic/sonic/infrasonic waves, liquid level indicators for physical variable measurement, etc. The problem of granular material or powder material level height, etc., can solve the problem that the material level cannot be accurately measured and the sealing performance is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

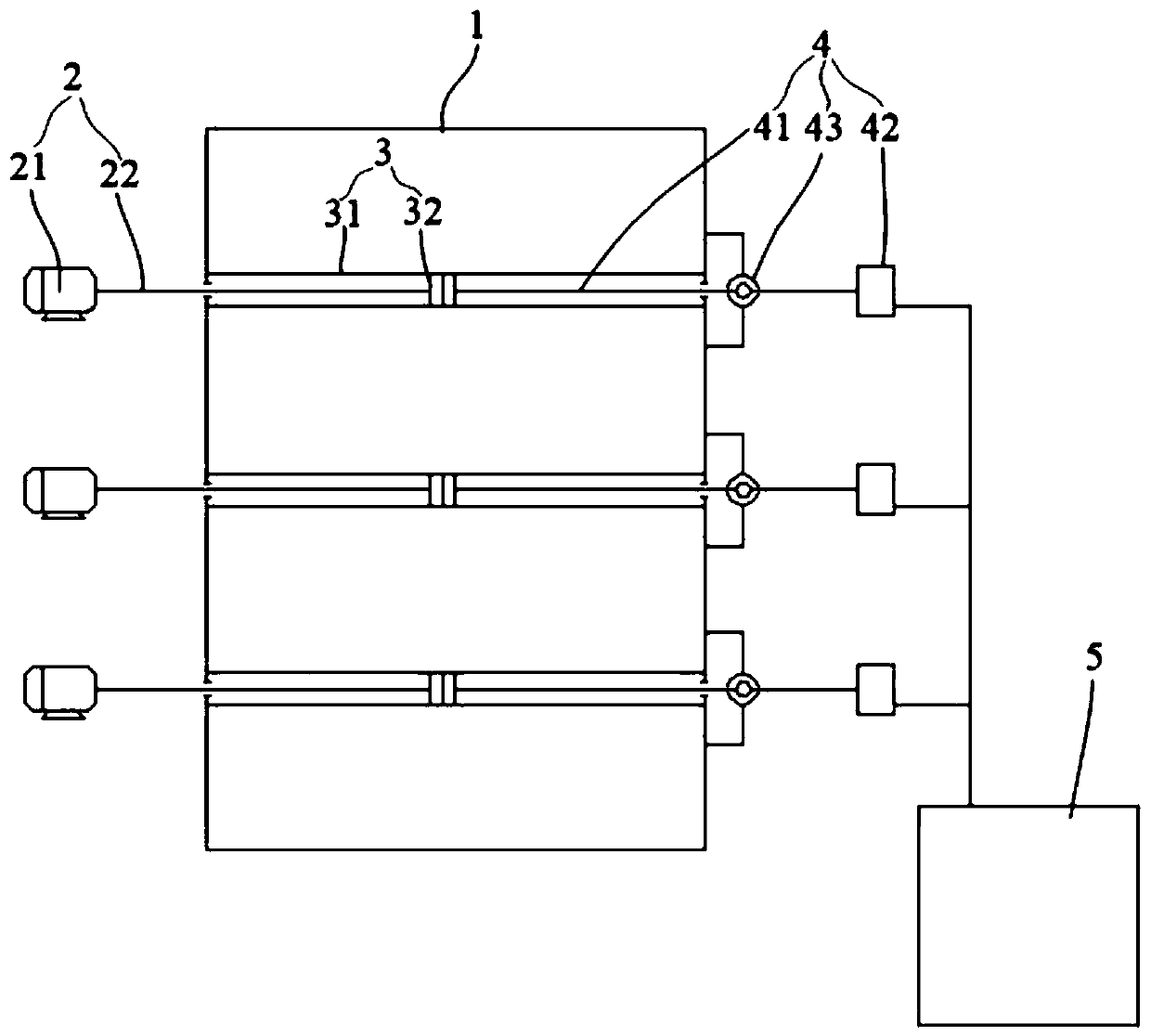

[0033] refer to figure 1 As shown, as an embodiment, the vibration detection system 4 includes a swing transmission rod 41 and a vibration detection unit 42 , one end of the swing transmission rod 41 is connected to the vibration tube 31 or the moving part 32 , and the other end is connected to the vibration detection unit 42 .

[0034] It should be noted here that the swing transmission rod 41 can be connected to the moving part 32 or the vibrating tube 31, and figure 1 In the illustration, only the swing transmission rod 41 can be connected to the moving part 32 is taken as an example for illustration, as long as the vibration tube 31 or the moving part 32 vibrates to drive the swing transmission rod 41 to vibrate synchronously.

[0035] Since the vibrating tube 31 or the moving part 32 is connected to one end of the swing transmission rod 41, the vibrating tube 31 or the moving part 32 can transmit the vibration information to the vibration detection unit 42 connected to th...

Embodiment 2

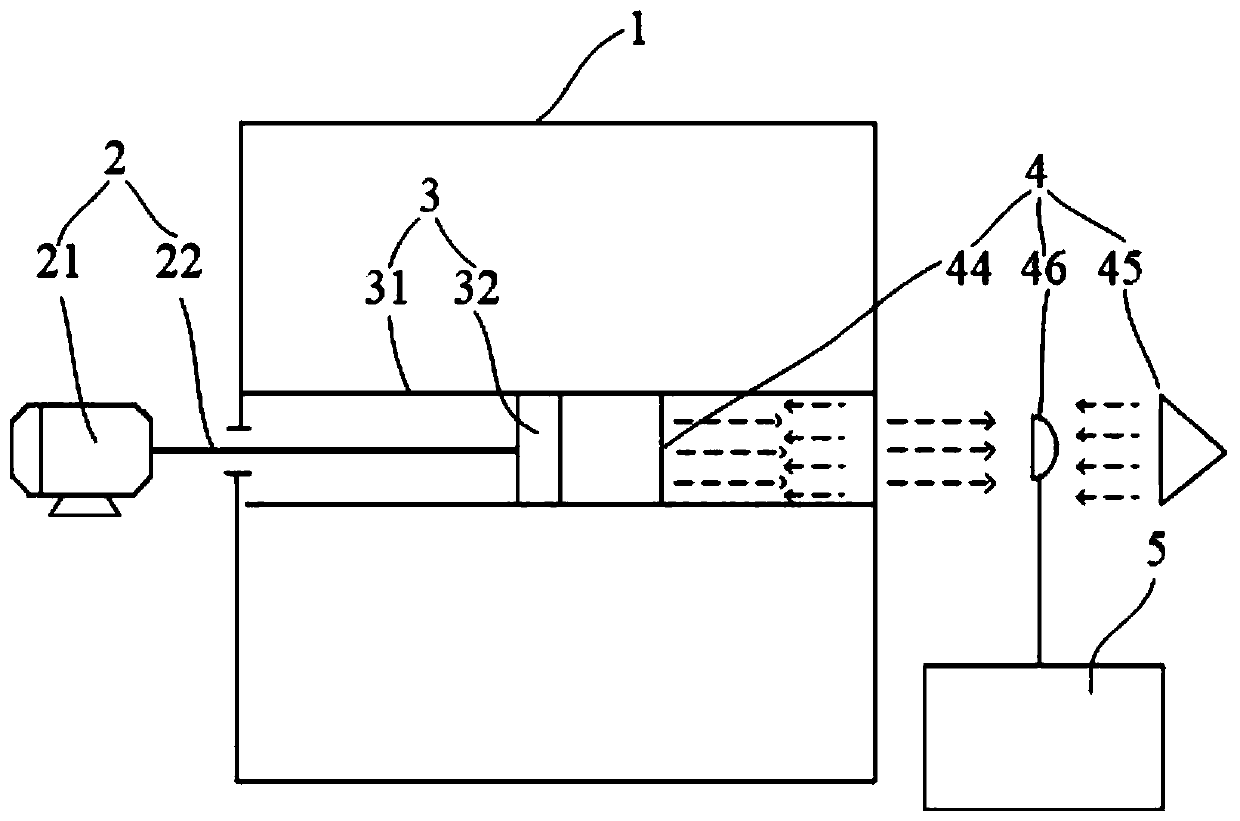

[0052] refer to figure 2 As shown, as another embodiment, the vibration detection system 4 includes a reflective mirror 44 arranged on the moving part 32 or the vibrating tube 31, and a detection light source 45 and a light sensor 46 arranged outside the container 1 to be tested. When the driving system 2. When not working, the light emitted by the detection light source 45 is irradiated on the reflective mirror 44, and the reflective mirror 44 can reflect the light irradiated on it to the photosensitive element 46.

[0053] When the drive system 2 is working, if the material level in the container 1 to be tested does not reach the position of the vibrating tube 31, that is, the vibrating tube 31 does not contact the material inside the container 1 to be tested, then the moving part 32 and the vibrating tube 31 are in a vibrating state. When the vibrating tube 31 is in a vibrating state, the vibrating tube 31 is not straight, so that the light emitted by the detection light s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com