Nuclear fuel assembly multifunctional detecting device based on array type flexible detection

A nuclear fuel assembly and detection device technology, which is applied in the direction of measurement devices, electromagnetic measurement devices, nuclear power generation, etc., can solve the problems of poor detection accuracy, difficulty in centering, and inability to adapt to local deformation of fuel rods, etc., to achieve close adhesion The effect of combining and vertical centering and improving the detection accuracy of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

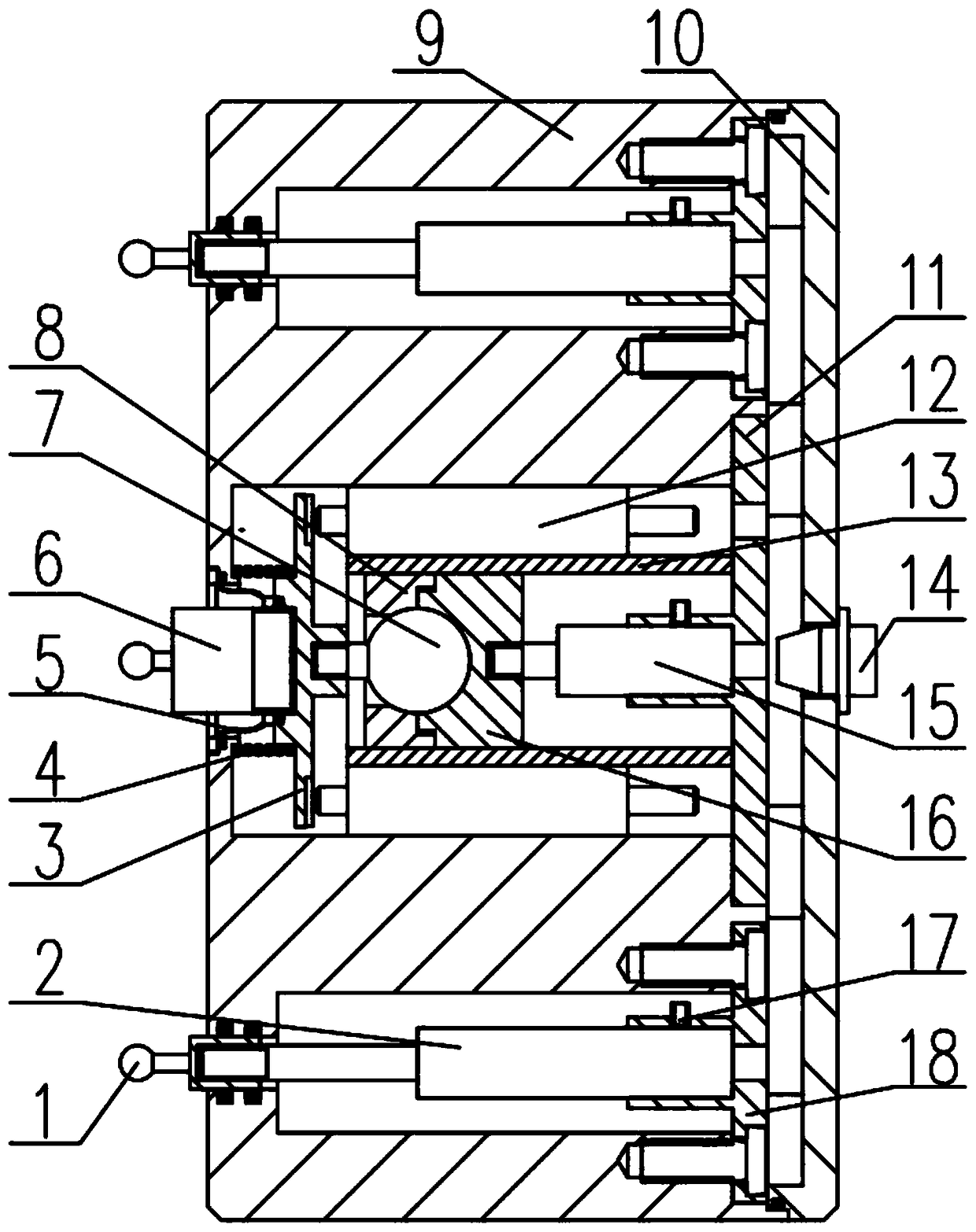

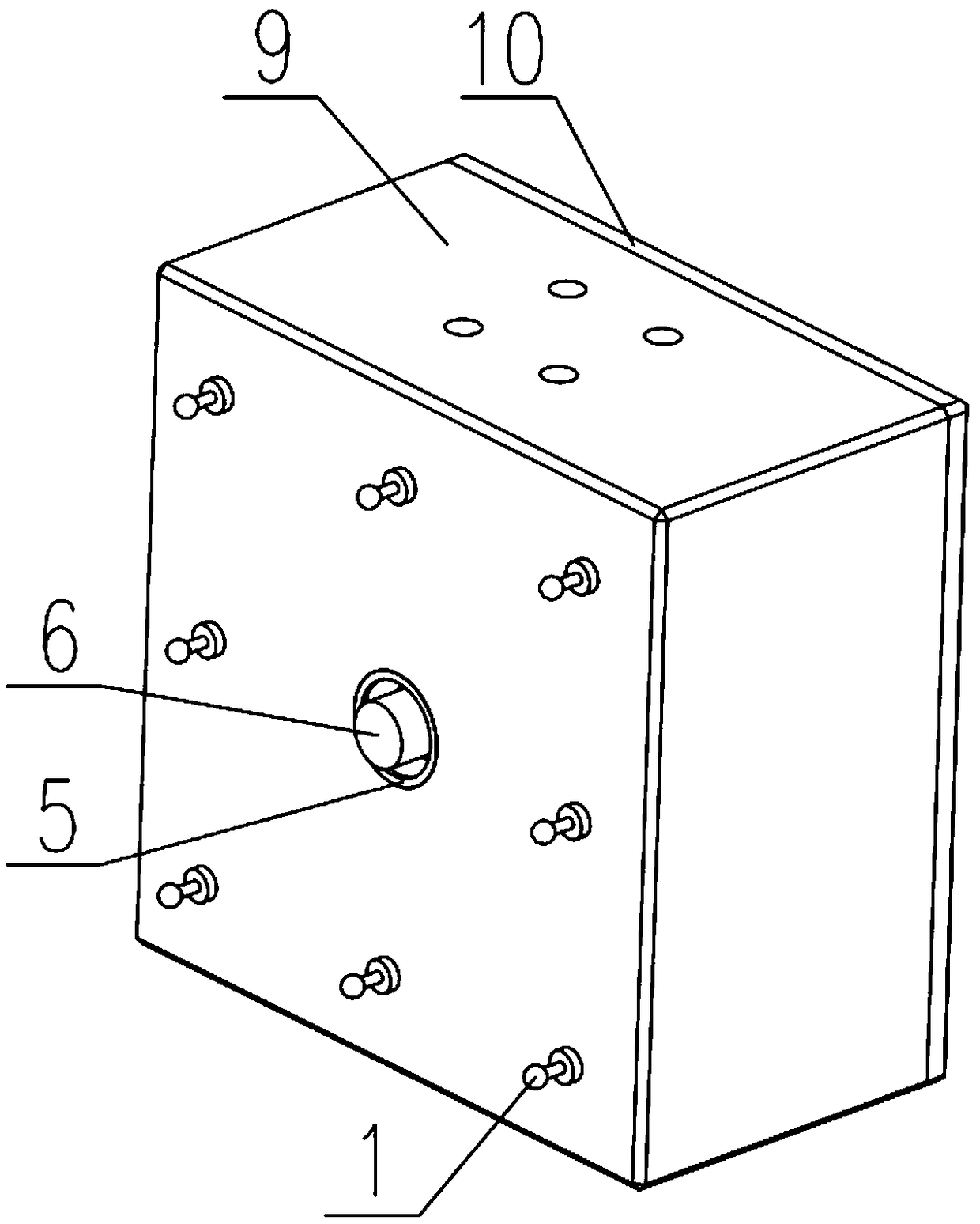

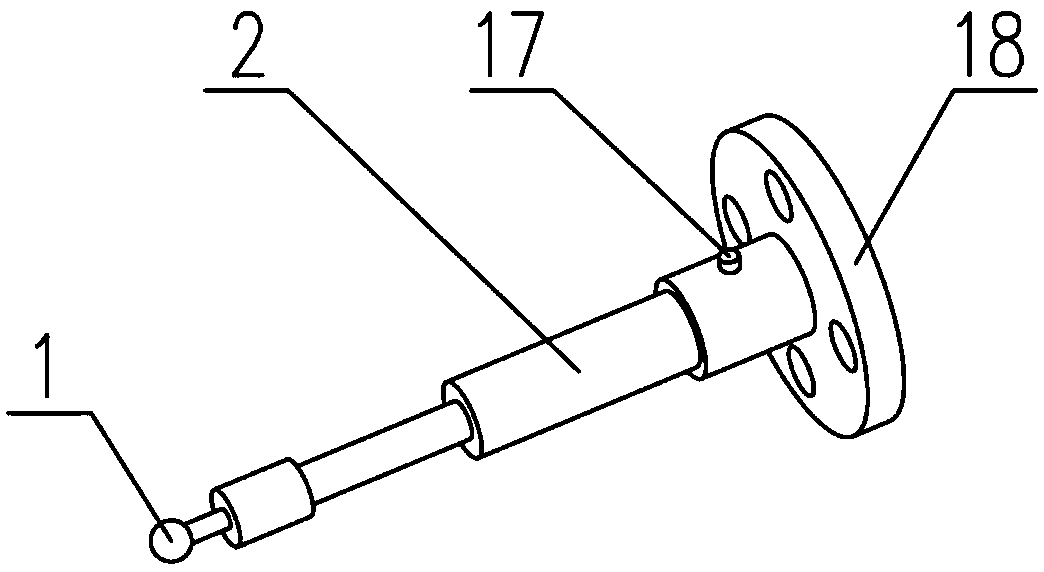

[0032] Describe the present invention in detail below in conjunction with embodiment and accompanying drawing. The embodiment is based on the specific implementation carried out on the premise of the technical solution of the present invention, and provides detailed implementation methods and processes. However, the protection scope of the claims of the present application is not limited to the description of the following embodiments. The above-mentioned orientation words such as "front, back; up and down" are for the sake of clarity of description and only have a relative meaning. Generally, the side of the detection probe is taken as the front, the side of the main installation cover is taken as the back, and the other side is taken as the other. Benchmarks for localizers.

[0033] The present invention provides a multifunctional detection device for nuclear fuel assemblies based on array-type flexible detection (referred to as the detection device, see Figure 1-7 ), com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com