Four-axis linkage sealing device for triangular beam of ring cooler

A sealing device and four-axis linkage technology, which is applied in the treatment of discharged materials, furnaces, lighting and heating equipment, etc., can solve problems such as matching, air leakage, and lack of accuracy, and achieve the effect of making up for non-matching.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below with reference to the accompanying drawings.

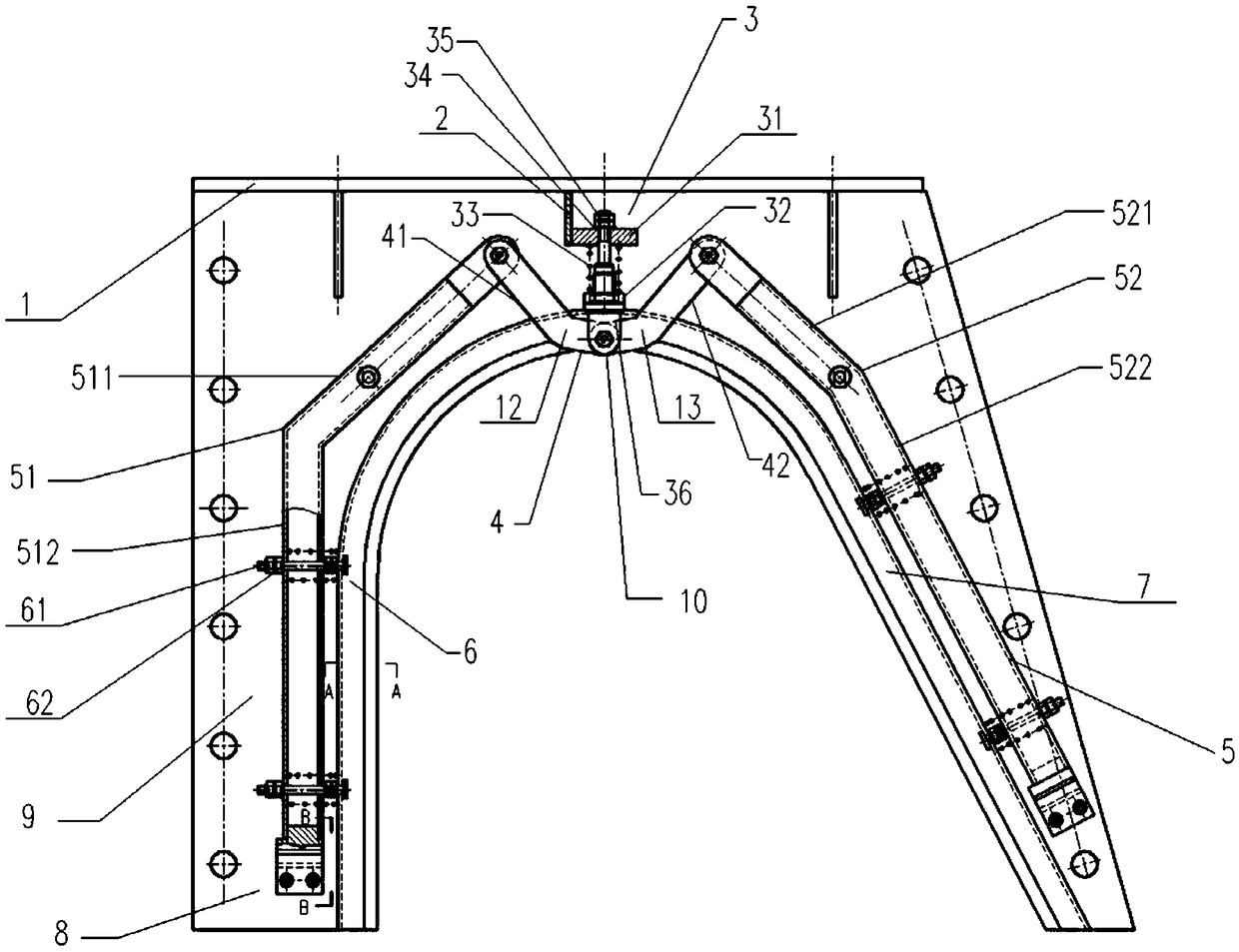

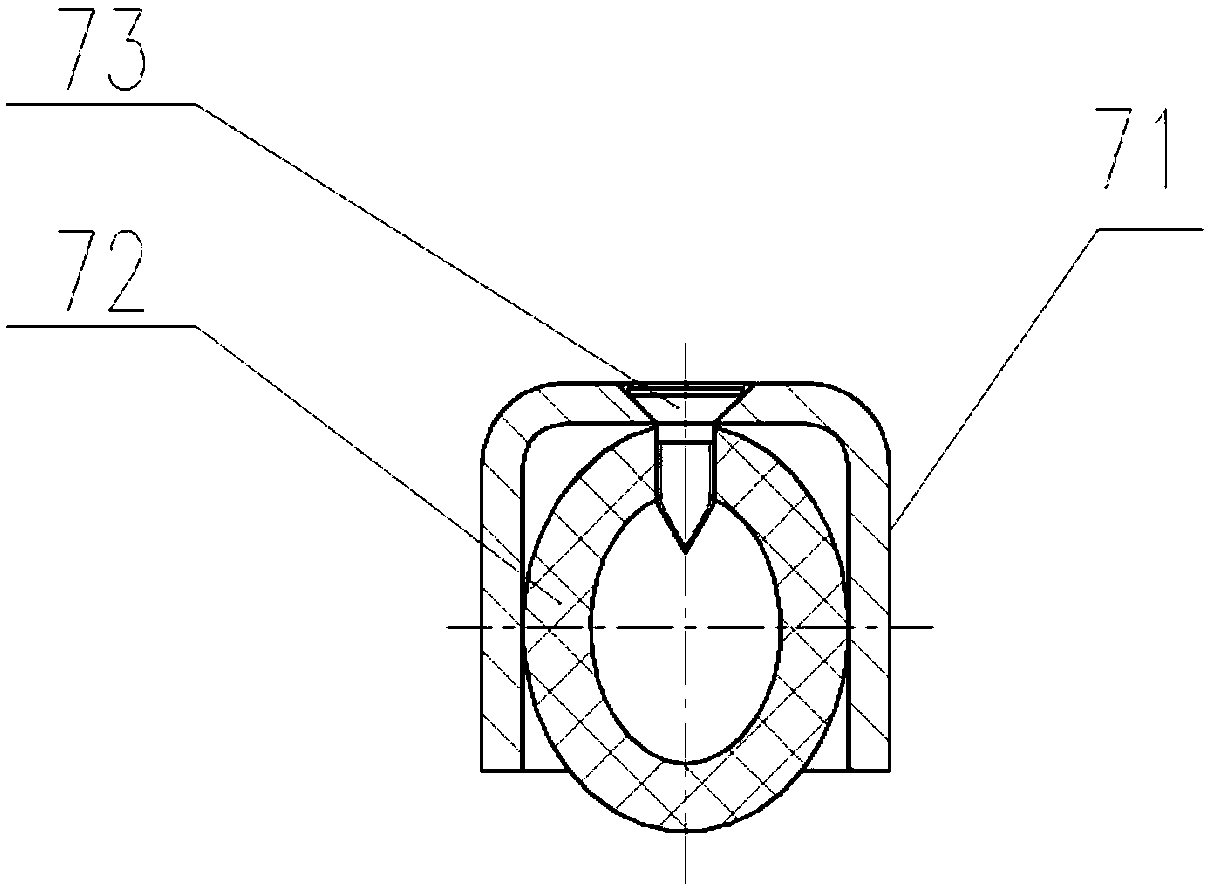

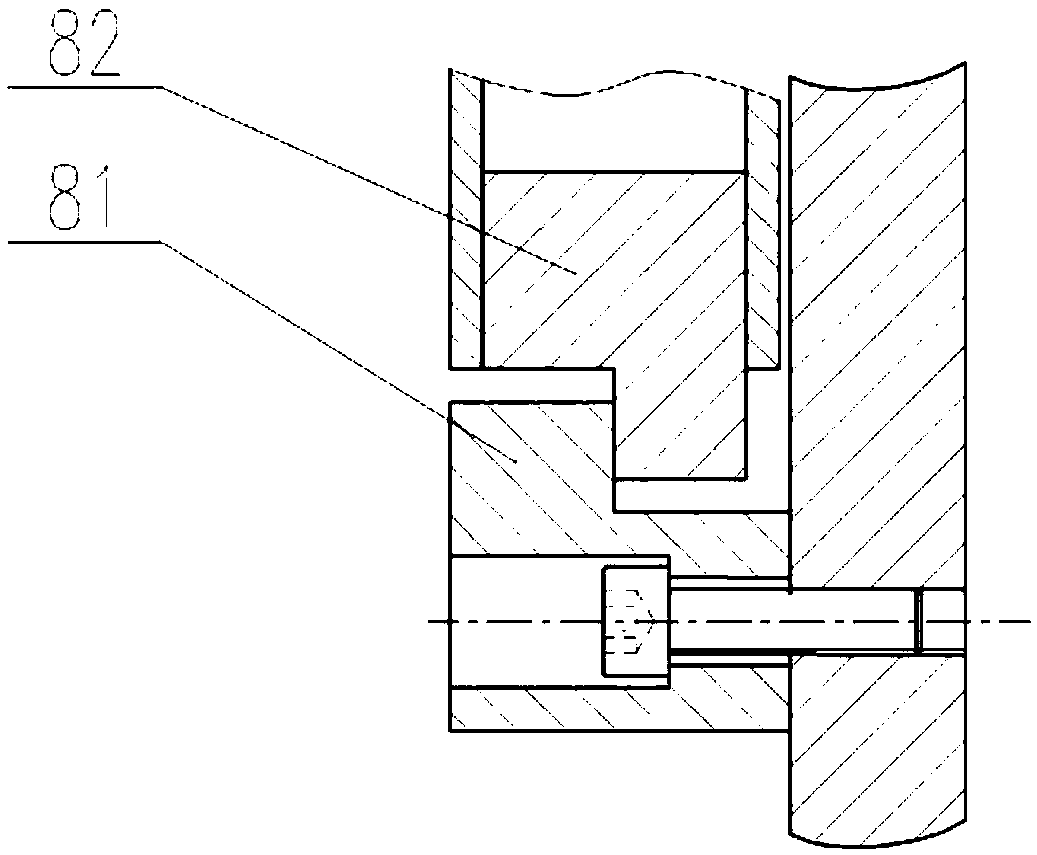

[0016] like figure 1 As shown in , the ring cooler triangular beam four-axis linkage sealing device, the sealing device is installed on the U-shaped square groove 7, the sealing device includes a vertical plate 1, a reinforcing rib 2, an upper spring device 3, a push rod 4 and a movable long rod 5 , the vertical plate 1 is fixed with a reinforcing rib 2 by welding or bolts, and the reinforcing rib 2 is connected with an upper spring device 3 by welding or bolting. The shaped square groove 7 is separated from the triangular beam, the other end of the upper spring device 3 is fixedly connected to the U-shaped square groove 7 , and the upper spring device 3 is connected to the push rod 4 and the movable long rod 5 in turn.

[0017] The upper spring device 3 includes a spring seat 31, a spring pressure adjusting nut 32, a spring 33, a flat washer 34, a mandrel adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com