PDCdrill bit for rock breaking by thermal spalling

A drill bit and rock-breaking technology, applied in the field of PDC drill bits for thermal peeling and rock-breaking, can solve the problems of PDC bit failure and poor drilling effect, and achieve the goal of improving rock-breaking efficiency, prolonging service life, and reducing the difficulty of penetrating into formations. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following non-limiting examples illustrate the invention.

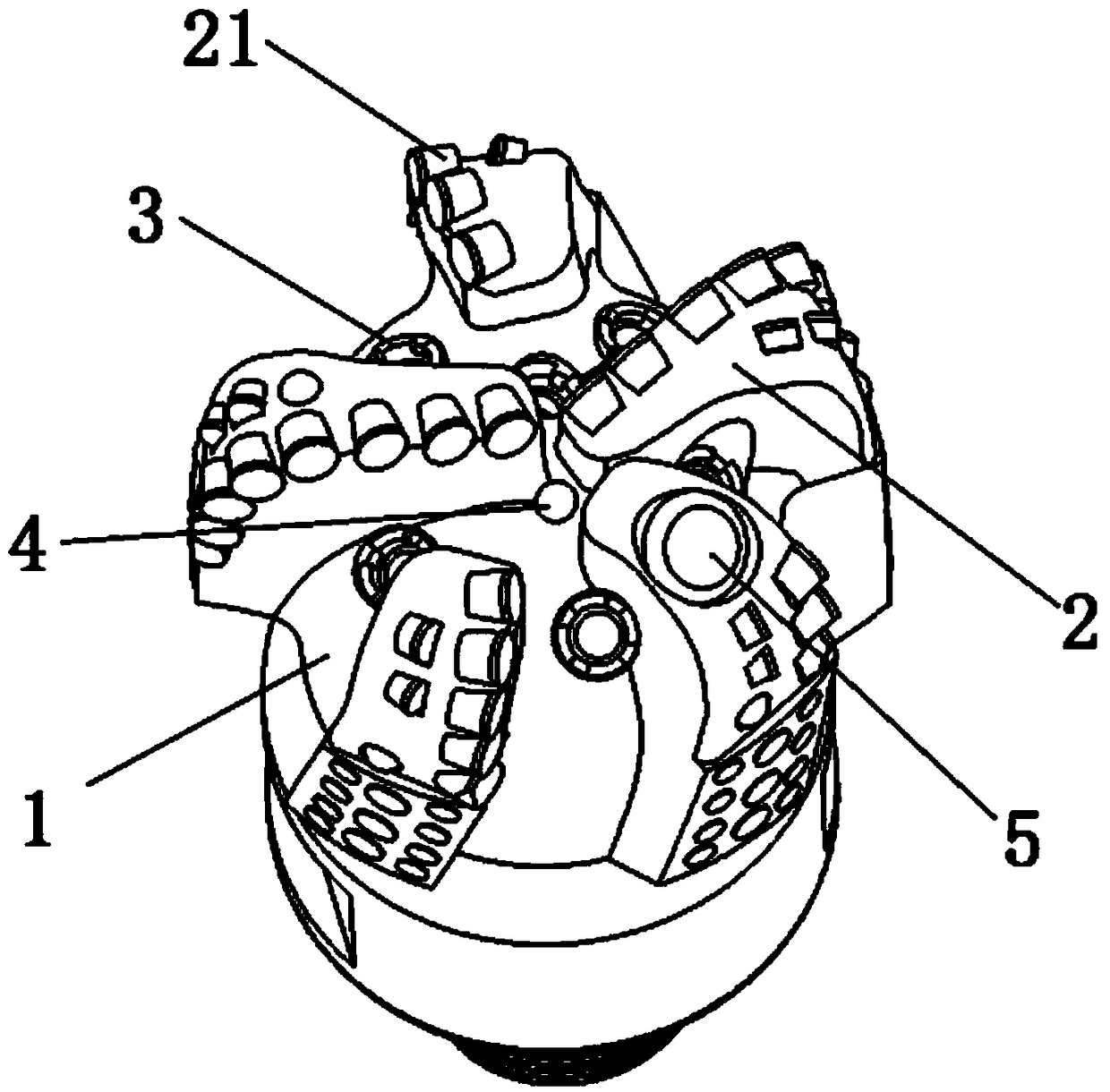

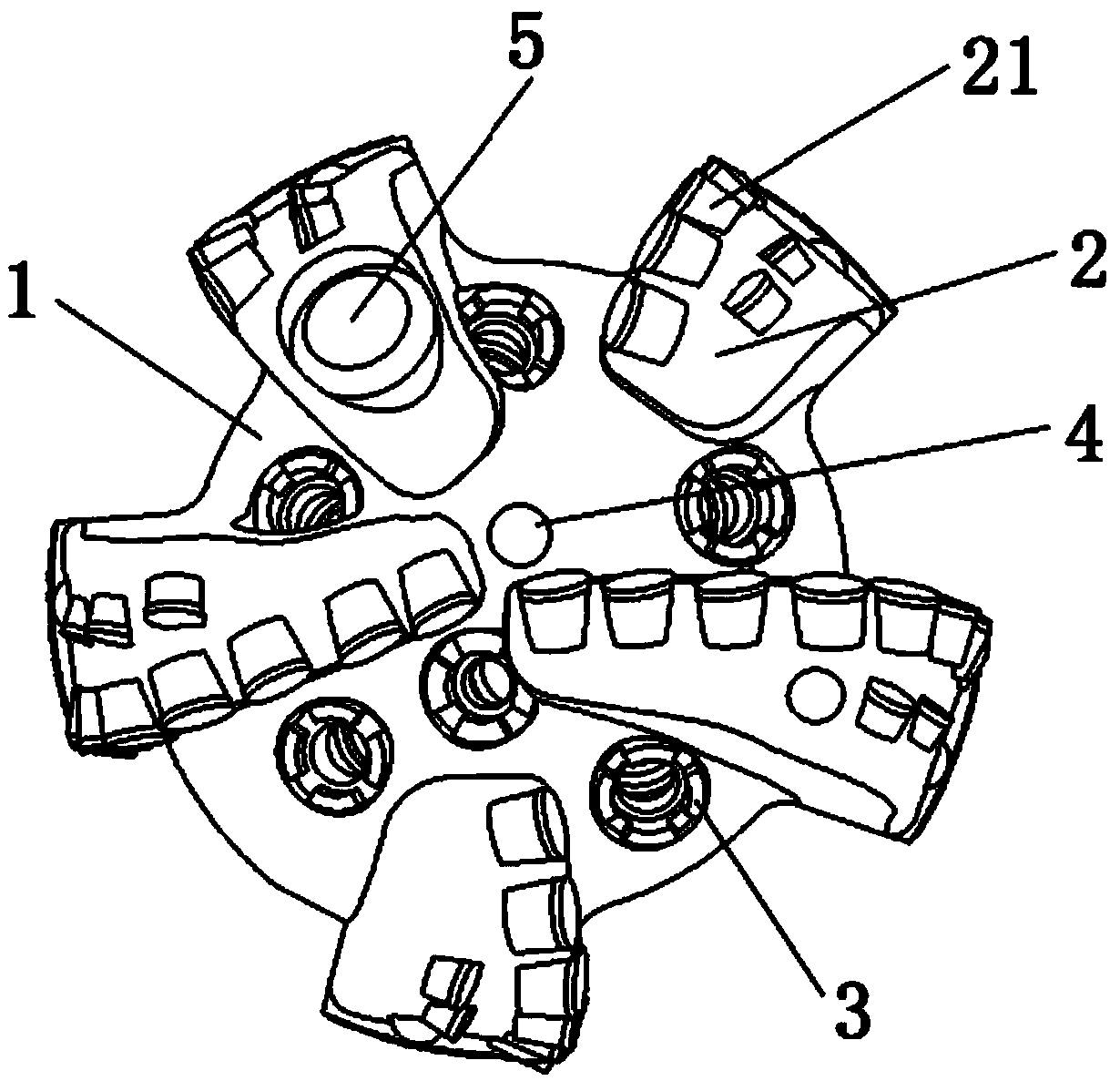

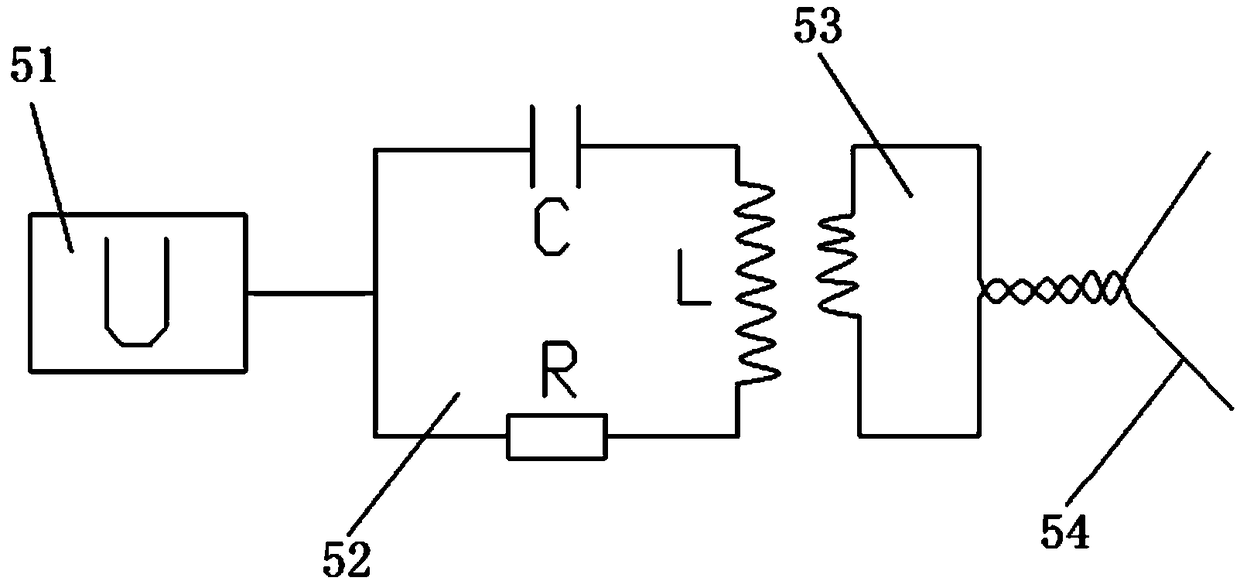

[0026] Such as figure 1 , 2 , shown in 3, a kind of PDC drill bit of thermal spalling and broken rock, comprises drill bit body 1, fixed blade 2, is provided with PDC tooth 21, water hole or nozzle 3 on the fixed blade, is characterized in that: the cutter of drill bit At least one electromagnetic wave generator 5 is arranged on the wing, and the electromagnetic wave generator includes a DC power supply 51, an RLC circuit 52, a high-frequency amplifier 53, and a transmitting antenna 54, and a central water hole 4 is arranged at the core of the drill bit, and the drill bit is a steel body drill bit.

[0027] Preferably, the frequency of the electromagnetic wave is 3GHz-300GHz.

[0028] Preferably, the temperature of the rock heated by electromagnetic waves is controlled at 300°C-500°C.

[0029] Preferably, the depth of the electromagnetic wave penetrating the rock is controlled at 20cm-30cm.

[0030] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com