Rock breaking machine with telescopic side beams

A rock breaker and edge beam technology, which is applied in drilling equipment, drilling equipment and methods, and earthwork drilling and mining, etc., can solve the problem of large difference in length at both ends, large downward shear force of the rock breaker, and insufficient use of the ripper. and other problems, to achieve the effect of easy installation, simple and reliable structure, compact and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

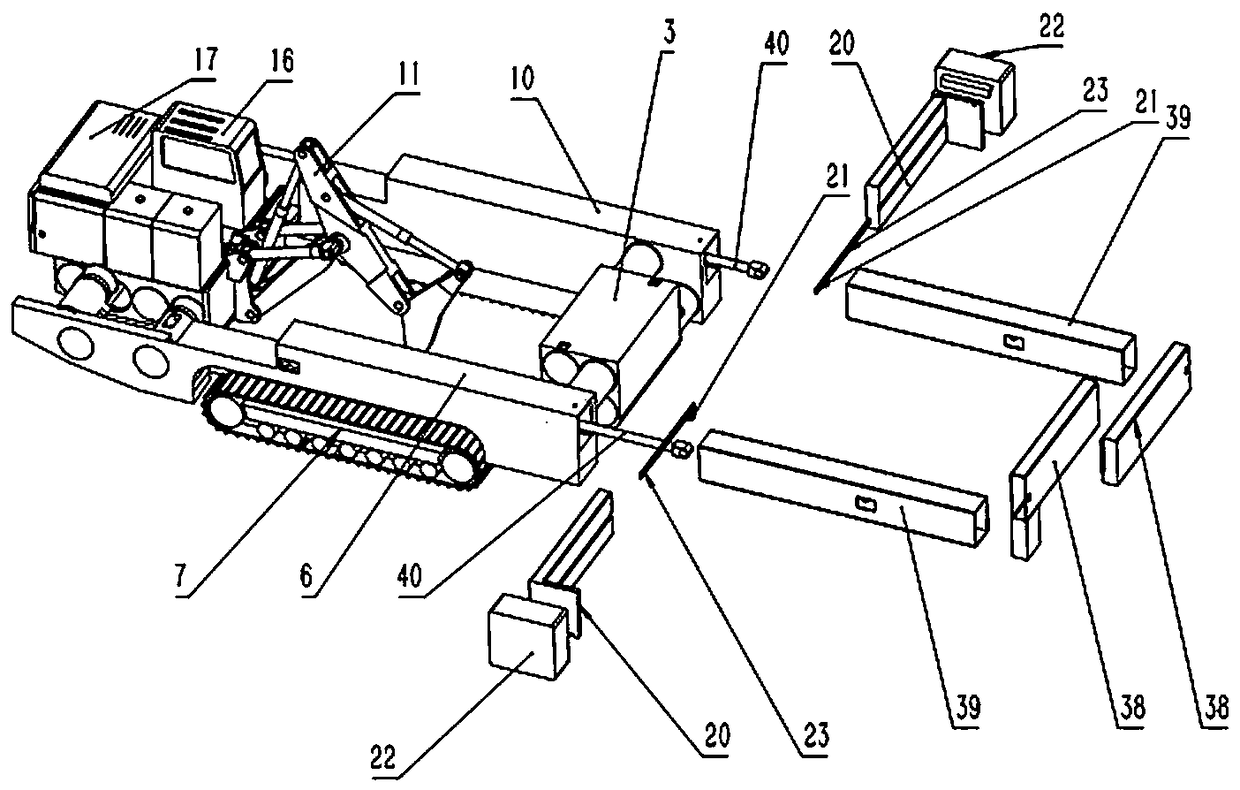

[0028] refer to figure 1 , the rock breaker, including a power part 17, a control room 16, a car body with a hollow area in the up and down direction and a rock arm 11 located in the hollow area, walking 7 is arranged on both sides of the car body, and the rock arm 11 can be equipped with a bucket The ripper with teeth carries out the rock-breaking operation. The side beams 6 and 10 on both sides of the vehicle body are provided with a hollow cavity 43 along the longitudinal direction. , the longitudinal telescopic block 39 is slidingly connected with the cavity, one end of the longitudinal telescopic block 39 is located in the cavity, and the other end is located outside the cavity, the telescopic drive device 40 can drive the longitudinal telescopic block 39 to expand and contract in the cavity, and the longitudinal telescopic block 39 is located at one end outside the cavity to connect There is a counterweight assembly.

[0029] The counterweight assembly comprises a horiz...

Embodiment 2

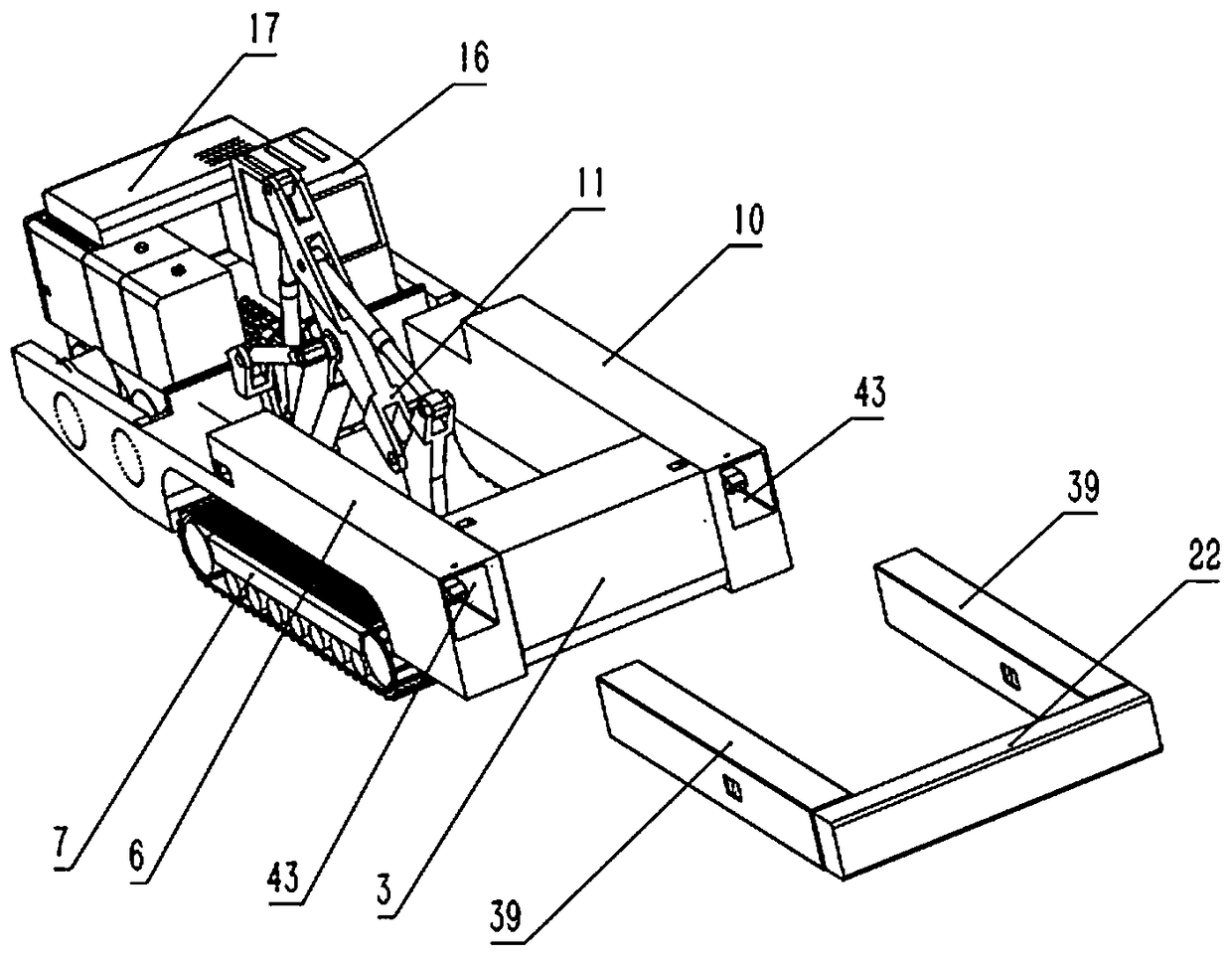

[0034] refer to Figure 4 , the rock breaker, including a power part 17, a control room 16, a car body with a hollow area in the up and down direction and a rock arm 11 located in the hollow area, walking 7 is arranged on both sides of the car body, and the rock arm 11 can be equipped with a bucket The ripper with teeth carries out the rock-breaking operation. The side beams 6 and 10 on both sides of the vehicle body are provided with a hollow cavity 43 along the longitudinal direction. , the longitudinal telescopic block 39 is slidingly connected with the cavity, one end of the longitudinal telescopic block 39 is located in the cavity, and the other end is located outside the cavity, the telescopic drive device 40 can drive the longitudinal telescopic block 39 to expand and contract in the cavity, and the longitudinal telescopic block 39 is located at one end outside the cavity to connect There is a counterweight assembly.

[0035] The counterweight assembly is a counterweig...

Embodiment 3

[0039] The rock breaker includes a power part 17, a control room 16, a car body with a hollow area in the upper and lower directions, and a rock arm 11 located in the hollow area. Walking 7 is arranged on both sides of the car body, and the rock arm 11 can be equipped with a bucket tooth. The ripper carries out the rock-breaking operation, and the side beams 6 and 10 on both sides of the car body are longitudinally provided with a hollow cavity 43, and the length direction of the walking 7 is longitudinally arranged along the side beams 6 and 10, and a longitudinal telescopic block 39 is arranged in the cavity. The longitudinal telescopic block 39 is slidingly connected to the cavity. One end of the longitudinal telescopic block 39 is located in the cavity, and the other end is located outside the cavity. The telescopic drive device 40 can drive the longitudinal telescopic block 39 to expand and contract in the cavity. Heavy components.

[0040] The counterweight assembly incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com