Preparation method of nano Silicalite-1 molecular sieve

A molecular sieve and nanotechnology, applied in the field of preparation of nano-Silicalite-1 molecular sieve, can solve problems such as easy aggregation of crystal nuclei, and achieve the effects of simple and easy operation, production cost saving and dosage saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The present invention uses mesoporous silica as a precursor for the preparation of nano-Silicalite-1 molecular sieves by steam-assisted crystallization. The specific steps are:

[0027] Step 1, the material ratio required for the synthesis of nano Silicalite-1 molecular sieve is SiO 2 :yR:mH 2 O, wherein: R is template, y=0.05~0.5, m=0.1~5, calculate the amount of corresponding material according to need;

[0028] Step 2, weigh the required template agent (organic amine) and a certain amount of water, stir and dissolve at room temperature evenly. The templating agent is at least one of tetraethylammonium hydroxide, tetrapropylammonium hydroxide, tetrapropylammonium bromide and tetrapropylammonium chloride;

[0029] Step 3, impregnating the mesoporous silica with the above mixed solution, and then drying at room temperature to volatilize part of the water until the material composition ratio in the raw material is reached to obtain the initial synthesis mixture. The s...

Embodiment 1

[0033] Example 1: Mesoporous silica

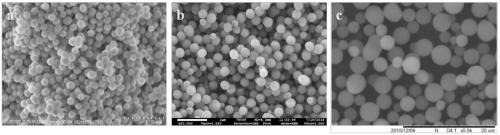

[0034] The average particle size parameters of spherical mesoporous silica used are shown in Table 1, and the scanning electron microscope images of mesoporous silica are shown in figure 1 .

[0035] Table 1 Spherical mesoporous silica particle size parameter table

[0036] mark

Embodiment 2

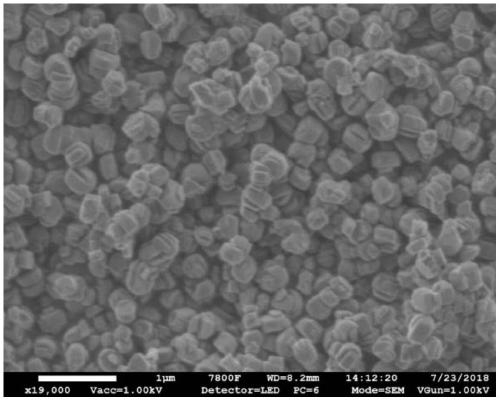

[0037] Embodiment 2: the preparation of nano Silicalite-1

[0038]First, tetrapropylammonium hydroxide was added into deionized water, stirred and dissolved to obtain a mixed solution. A certain amount of the above solution was taken to impregnate the mesoporous silica, and dried at room temperature for a period of time to obtain a solid mixture. The above solid mixture was transferred to the upper plate of the stainless steel autoclave, and water was added to the bottom of the autoclave. Seal the stainless steel reaction kettle, put it in an oven, and crystallize at 100-200°C for 12-150 hours. Cool rapidly after the reaction, separate the solid product, wash with deionized water, dry at 110°C in air atmosphere and bake at 550°C for 6 hours to obtain nano-Silicalite-1 molecular sieve.

[0039] The preparation process of using other templates is the same as the preparation process of tetrapropylammonium hydroxide as the template.

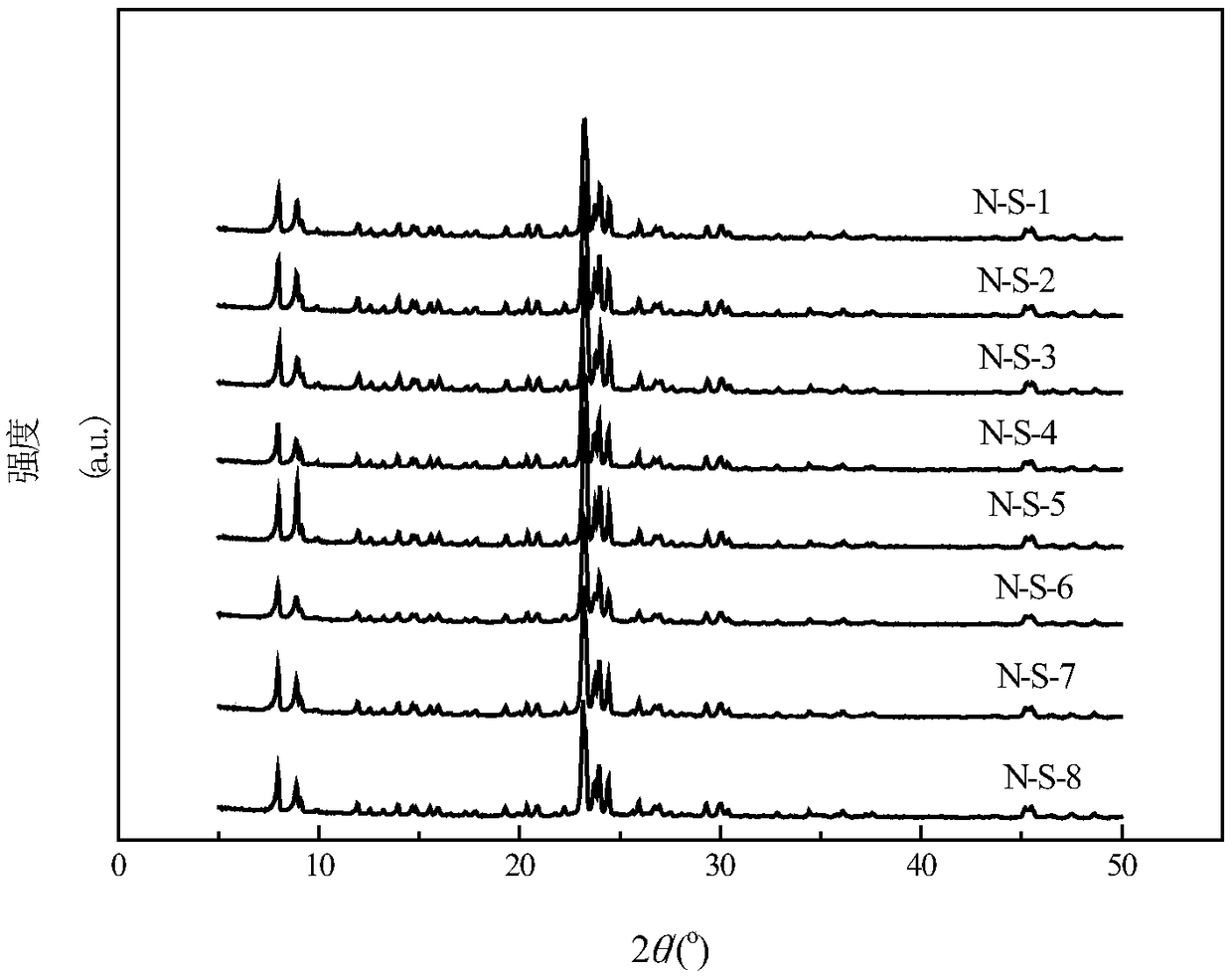

[0040] The samples prepared for each reacti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com