Conveying device for air conditioner top cover machining

A technology of a transmission device and a top cover, applied in the field of sheet metal processing, can solve problems such as easy sliding, achieve the effects of compact structure, improve transmission efficiency, and save placement time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

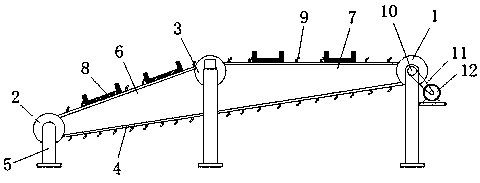

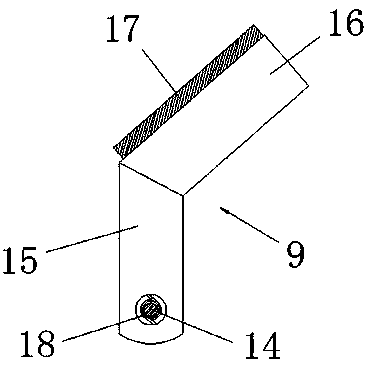

[0022] see Figure 1-4 As shown, a transmission device for air-conditioning top cover processing includes a main transmission wheel 1, a slave transmission wheel 2, a guide wheel 3 and a transmission belt 4, and the main transmission wheel 1, the slave transmission wheel 2 and the guide wheel 3 pass through the transmission belt 4 Be transmission connection with each other, one end of the main transmission wheel 1 is equipped with a rotating shaft 10, the rotating shaft 10 is connected with the rotating shaft 10 installed at one end of the motor 12 through a belt 11, several air-conditioning top covers 8 are installed on the top of the transmission belt 4, and the surface of the transmission belt 4 is set Several grooves 13, one end of the groove 13 is equipped with a rotating rod 14, and the outer wall of the rotating rod 14 is equipped with two baffle assemblies 9 through a scroll spring 18, and the baffle assembly 9 consists of a first baffle 15 and a second baffle. plate 1...

Embodiment 2

[0024] In addition, refer to Figure 1-4 , different from the above-mentioned embodiment 1, the main transmission wheel 1, the secondary transmission wheel 2, and the guide wheel 3 are all composed of a transmission roller 19 and a side plate 20, and the transmission roller 19 and the side plate 20 are rotationally connected, and the transmission roller 19 The friction between the transmission belt 4 makes the transmission belt 4 transport the top cover 8 of the air conditioner, and the outer walls of the two side plates 20 inside the guide wheel 3 are equipped with hydraulic pumps 21, and the hydraulic rods 22 pass through the side plates 20 to communicate with the hydraulic pumps 21. connection, the size of the side plate 20 is greater than the transmission roller 19, so the two push plates 23 will not touch the transmission belt 4, the two ends of the main transmission wheel 1, the slave transmission wheel 2, and the guide wheel 3 when they are pushed close to each other. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com