Dynamic seal contact surface friction rotating torque measuring device

A technology of rotational torque and measuring device, which is applied in the direction of measuring device, torque measurement, power measurement, etc., can solve the problem that the contact bearing friction has a great influence, cannot meet the requirements of accurate measurement of friction and rotational torque of dynamic seal contact surface, and the stirring work of sealing medium Consumption of friction torque and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

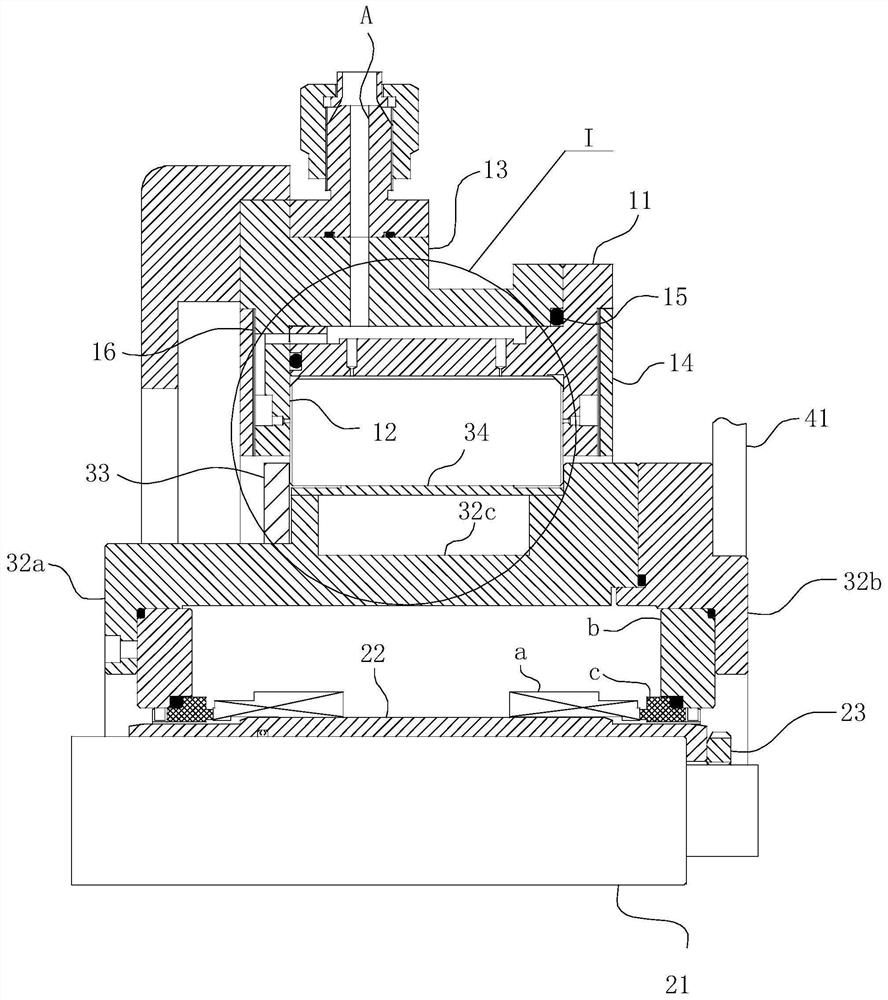

[0038] For ease of understanding, the specific structure and working method of the present invention are further described as follows:

[0039] Before the description, the following explanation is required: For the two-stage stepped hole, the cavity has two parts, the large-aperture section and the small-aperture section, and the hole port where the large-aperture section is located away from the small-diameter section forms the large-aperture end. ; Similarly, for the three-stage stepped shaft, the outer wall forms the small shaft diameter section, the middle shaft diameter section and the large shaft diameter section to distinguish each other.

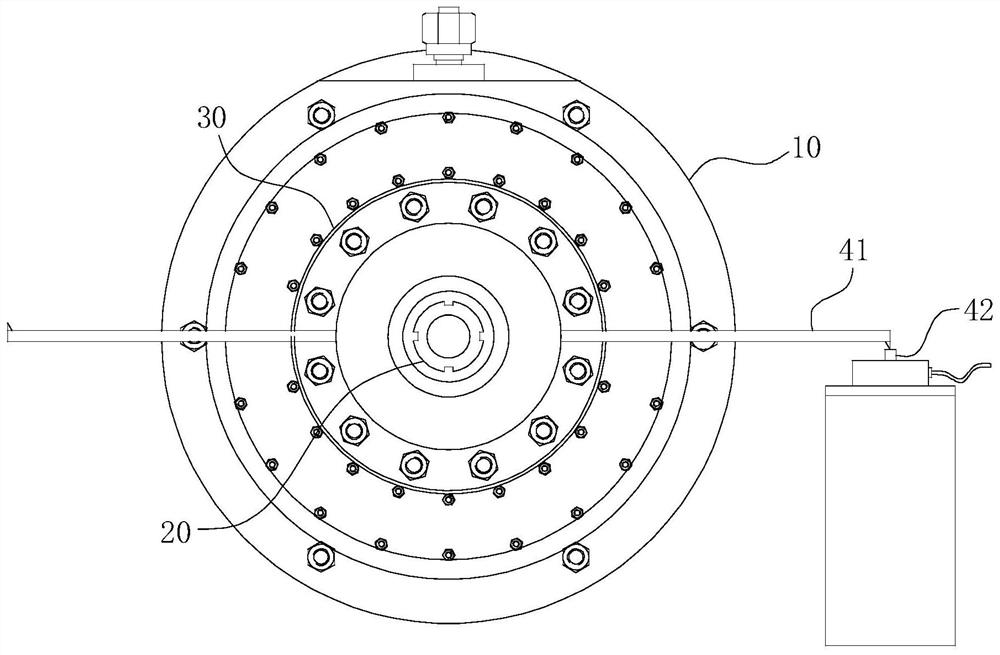

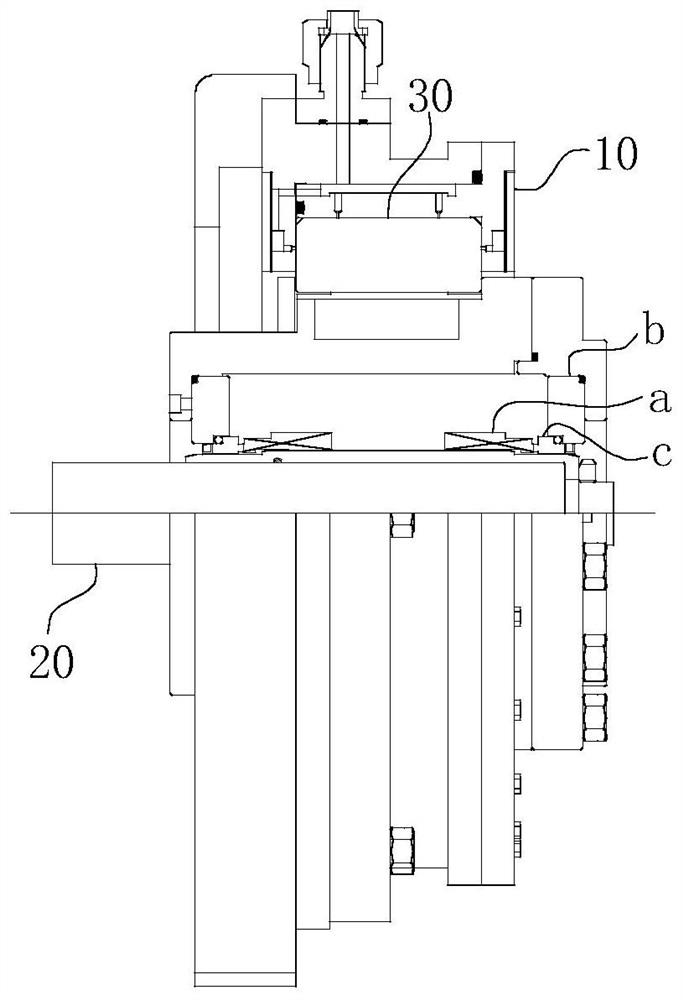

[0040] On the basis of the above explanation, the specific implementation structure of the present invention is based on Figure 1-2 For example, its main structure includes a moving part 20, a floating measuring part 30 and a static part 10 arranged in sequence from inside to outside. For the convenience of expressing the three, he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com