Picking and curing method for preventing rotten tobacco base parts in curing process

A tobacco leaf harvesting and roasting technology, applied in tobacco, tobacco preparation, application, etc., can solve the problems of tobacco leaf mildew and rot, achieve the effects of reducing mildew and rot, reducing the production of mildew and rotten tobacco leaves, and shortening the low-temperature yellowing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] For Yunyan 87 in a production place in Hubei Province, the tobacco leaves in the lower second shed are loaded on conventional hanging rods, and the method of harvesting and roasting of the present invention is adopted, and the following specific operations are carried out in the air-flow ascending intensive curing barn:

[0028] (1) Tobacco leaves are harvested after 10 am on sunny days, and the tobacco leaves show no dew when harvested.

[0029] (2) Use 1.35m tobacco rods to weave cigarettes, each rod weaves 90-110 pieces of tobacco, and holds 420 rods.

[0030] (3) After loading the tobacco, the temperature was raised to 38°C at a heating rate of 0.5 / h, the wet bulb temperature was controlled at 35°C, and the temperature was stabilized for 13 hours. The tip of the high-temperature layer tobacco leaves turned yellow.

[0031] (4) When the tip of the high-temperature layer tobacco leaves turns yellow, the temperature is raised to 40°C at a rate of 1°C / h, the wet bulb te...

Embodiment 2

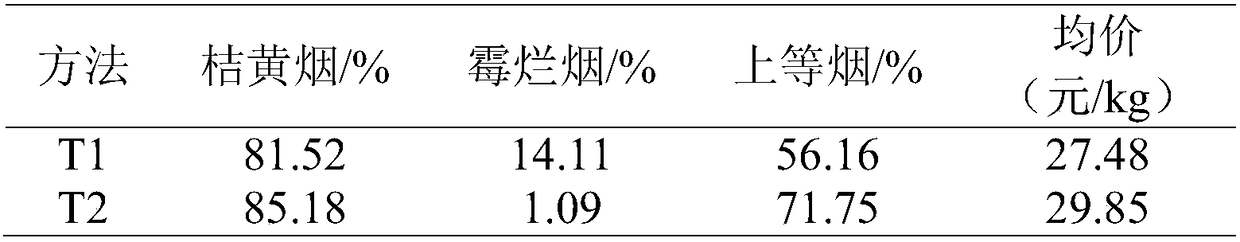

[0035] The comparative test of embodiment 2 conventional method of collecting and roasting and method of collecting and roasting described in the present invention

[0036] Test object: the central tobacco leaves of Yunyan 87 from a certain producing area in Hubei Province.

[0037] Conventional harvesting and roasting method (T1): pick tobacco in the morning, weave 120-130 pieces of tobacco per rod, and use a three-stage baking process (the existing conventional process) for baking. The heating rate of h is raised to 38°C, the wet bulb temperature is controlled at 36-37°C, and the temperature is stabilized until the tobacco leaves in the high temperature layer turn yellow by 6-7%, and the temperature is raised to 42°C at a heating rate of 1-2°C / h. Control the temperature at 36-37°C, stabilize the temperature until the tobacco leaves are 8-9% yellow, raise the temperature to 46-48°C at a heating rate of 0.5-1°C / h, control the wet bulb temperature at 37-38°C, and stabilize th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com