Construction method of small clear distance laminated tunnel

A construction method and technology of small clear distance, applied in tunnels, tunnel lining, earthwork drilling and mining, etc., can solve problems such as difficulty in guaranteeing engineering quality and complex construction of small clear distance stacked tunnels, so as to achieve safety in the construction process and solve engineering quality problems It is difficult to guarantee the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

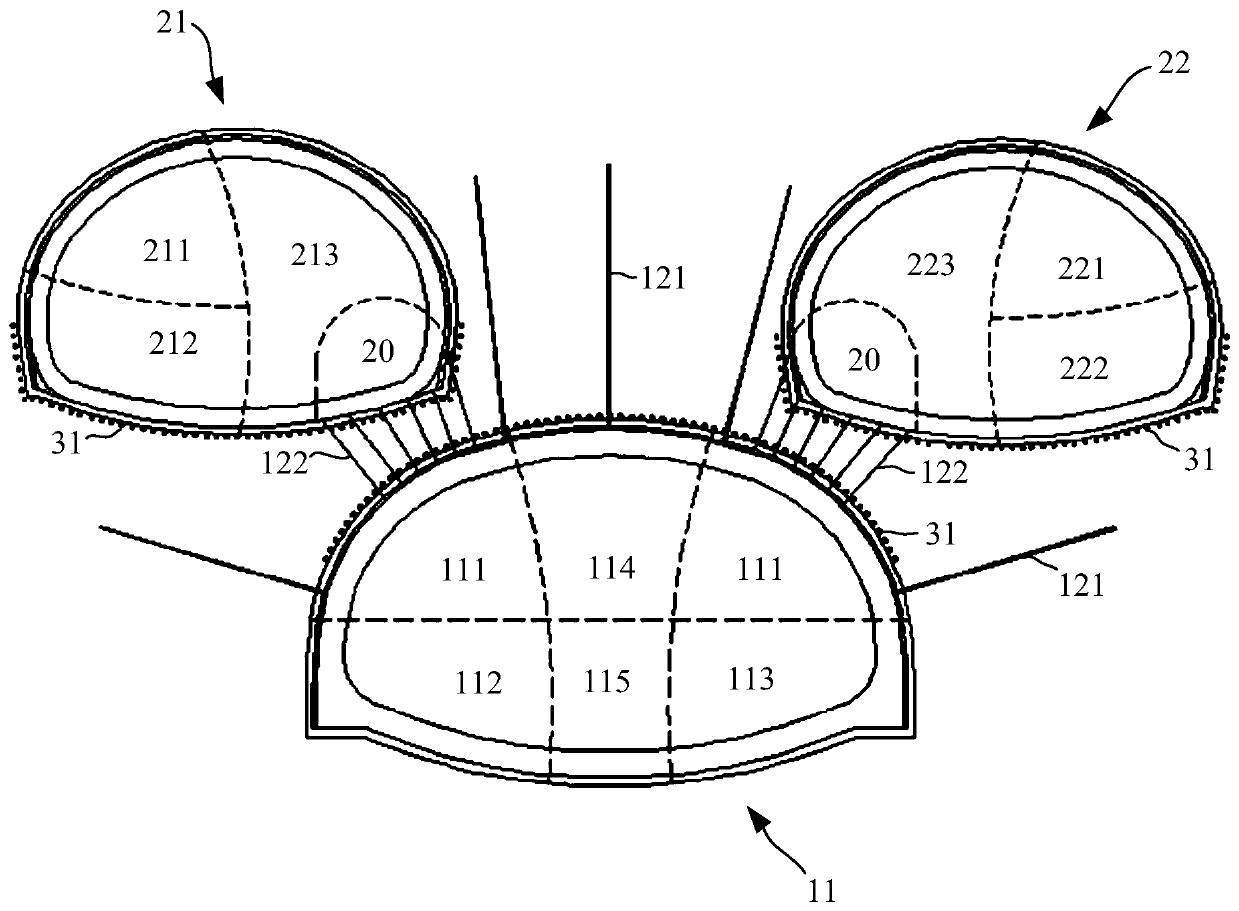

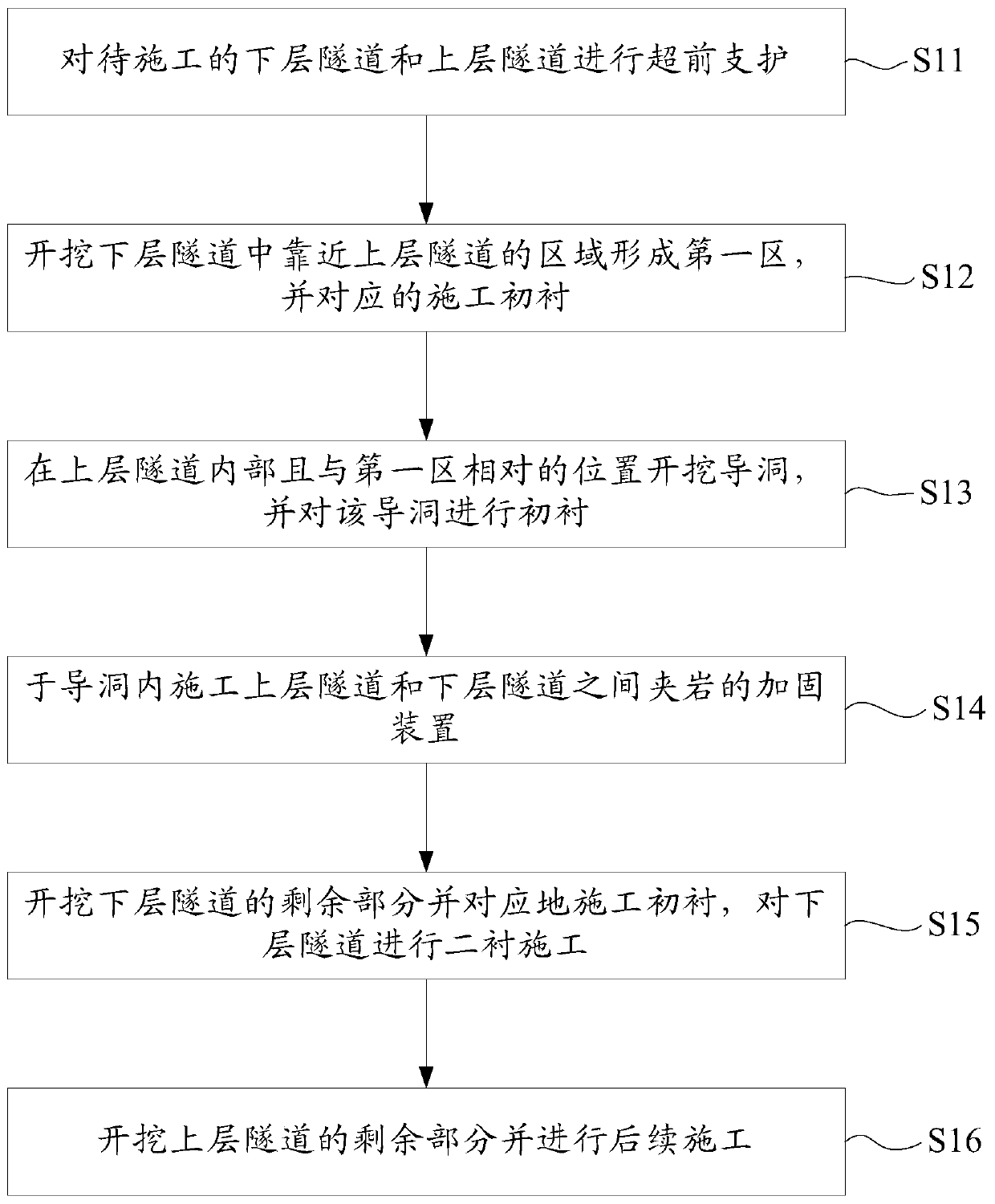

[0024] refer to figure 1 , the present invention provides a construction method of a small clear-distance laminated tunnel, by excavating a pilot tunnel in the upper tunnel, effectively reducing the damage to the secondary lining structure and rock interlayer of the lower tunnel due to the excavation and blasting vibration of the upper tunnel; The tunnel can complete the reinforcement of the interbedded rock through the pilot tunnel when most of the laminated tunnel has not been constructed, and the relevant mechanical equipment can be directly arranged in the pilot tunnel to facilitate the operation, so as to realize the convenient "top-to-bottom" interlayer rock The work of drilling or grouting solves the problems of complex construction and difficult quality assurance of small-space laminated tunnels, and makes the construction process safer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com