Design and construction method of a flexible compound ladder-shaped deep circular shaft assembled recyclable support structure

A technology of support structure and construction method, which is applied in shaft equipment, infrastructure engineering, well sinking, etc., to achieve the effects of easy recycling and reuse, easy installation, and high bearing capacity under pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

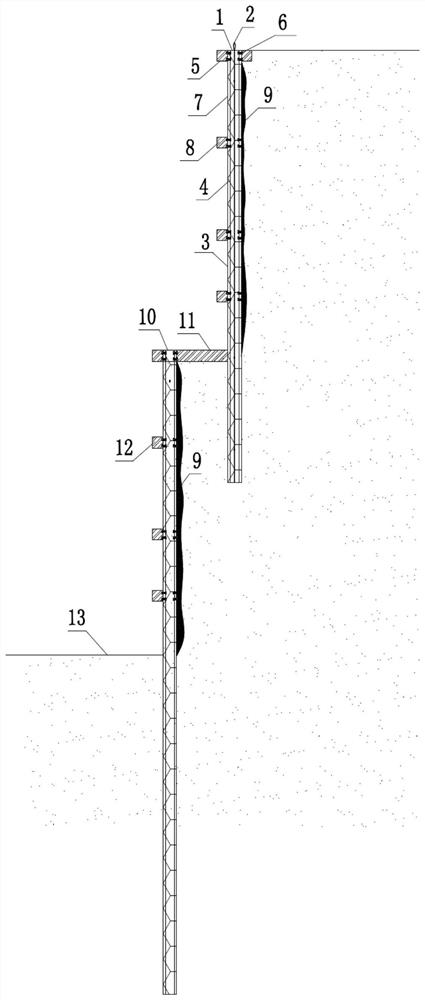

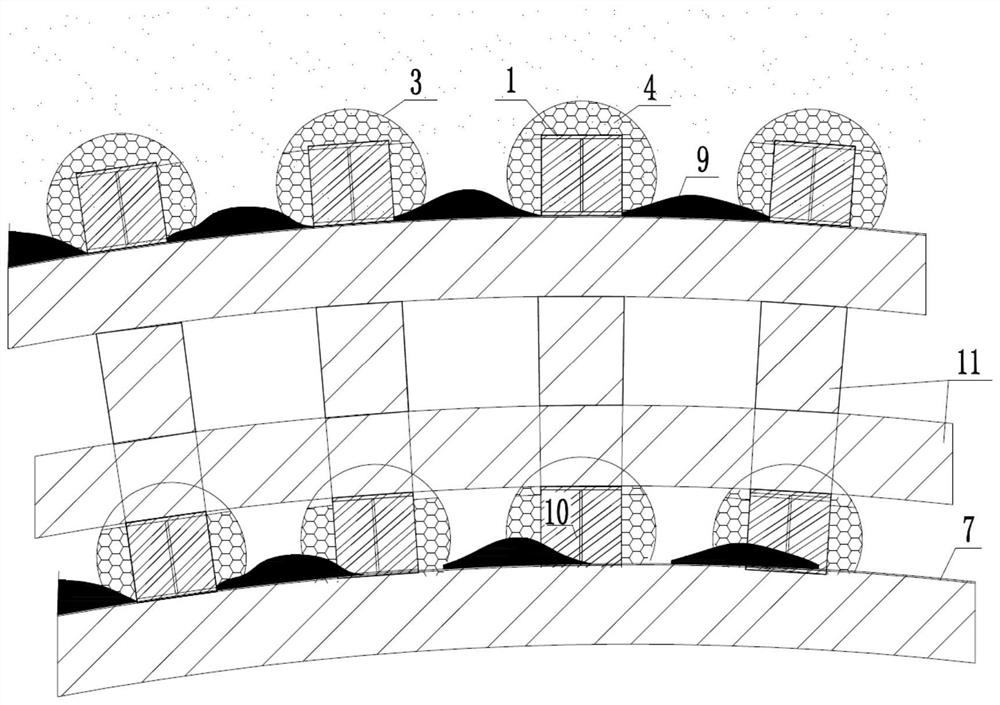

[0048] The present invention will be further described below in conjunction with accompanying drawing.

[0049] A method for the design and construction of a flexible composite ladder-like assembled recyclable support structure for deep circular shafts. The idea of mechanical precision manufacturing and on-site assembly standardized production, after completing the design work according to relevant information, the factory prefabricated and processed the corresponding support components, and then combined with polymer grouting technology to carry out the assembly construction of the site support structure; Backfilling in the foundation pit Afterwards, the recovery support structure can be removed for reuse and standardized design and construction.

[0050] The construction process specifically includes the following steps:

[0051] (1) The construction of the first layer of circular support piles, the specific steps are as follows:

[0052] (1) Processing of ring-shaped su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com