Six-in-one prefabricated concrete outer wall panel and production method thereof

A technology for concrete slabs and production methods, which is applied to building components, ceramic molding machines, buildings, etc., can solve the problems of increased cost, cumbersome manufacturing process, and easy damage to thermal insulation layers, and achieves increased bonding friction and tensile bonding. Intensity Satisfying Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that the orientation terms such as left, middle, right, up, and down in the examples of the present invention are only relative concepts or refer to the normal use state of the product, and should not be considered as restrictive .

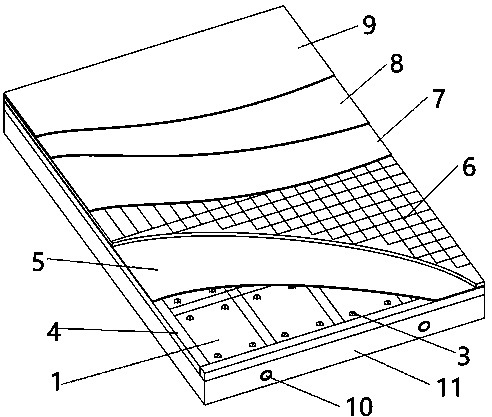

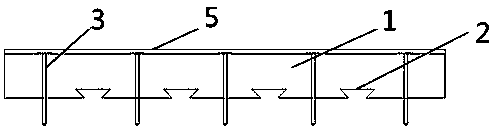

[0027] Such as figure 1 As shown, a six-in-one assembled concrete exterior wall panel includes a hydrophobic self-cleaning paint layer 9, a flexible board 8, an anti-cracking mortar layer 7, a grid cloth 6, and a fireproof dry-mixed mortar layer 5, which are fixed and connected sequentially from the outside to the inside. , thermal insulation board 1 and concrete slab 11, on said thermal insulation board 1, there are thermal insulation nails 3 uniformly distributed, one end of said thermal insulation nail 3 is located in said thermal insulation board 1, and the other end of said thermal insulation nail 3 is located in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com