Humic acid water-soluble fertilizer produced from juice, and preparation method thereof

A technology of water-soluble fertilizer and humic acid, applied in the field of water-soluble fertilizer, can solve the problems of restricting the innovative development and commercial application of humic acid fertilizer, low plant absorption and utilization rate, and high redox potential, so as to improve commercial value, crop absorption, Crop Easy Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

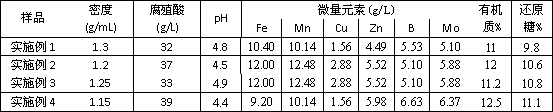

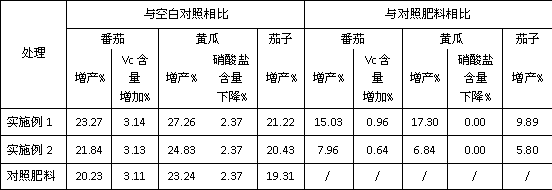

Embodiment 1

[0024] 1. Preparation of fermented fruit juice: Select fruits with qualified certificates of pesticide residue survey. The definition of fruits in the present invention includes but not limited to apples, peaches, pears, plums, apricots, kiwis, oranges, pineapples and other fruits. 5% of the fruit, the fruit with rotten fruit rate ≥ 5% is detected as unqualified rotten fruit. Use a crusher to crush the qualified fruit into a pulp and juice mixture with a particle size of 3-6mm, add compound enzymes, control the temperature at 50-70°C, control the stirring speed at 20-30rad / min, and enzymatically hydrolyze for 2 hours. Control the temperature of the enzymatically hydrolyzed material at 30-35°C, rotate at 50 rad / min, adjust the pH to 6-7, add beneficial compound bacteria to ferment for 24 hours, and take plate and frame filter to pass through a 0.25mm mesh to obtain qualified fermented juice .

[0025] The filter residue after pressure filtration and unqualified rotten fruit ar...

Embodiment 2

[0029]1. Preparation of fermented fruit juice: Select fruits with qualified certificates of pesticide residue survey. The definition of fruits in the present invention includes but not limited to apples, peaches, pears, plums, apricots, kiwis, oranges, pineapples and other fruits. 5% qualified fruit, and the fruit with rotten fruit rate ≥ 5% is detected as unqualified rotten fruit. Use a crusher to crush the qualified fruit into a pulp and juice mixture with a particle size of 3-6mm, add compound enzymes, control the temperature at 50-70°C, control the stirring speed at 20-30rad / min, and enzymatically hydrolyze for 2 hours. Control the temperature of the enzymatically hydrolyzed material at 30-35°C, rotate at 50 rad / min, adjust the pH to 6-7, add beneficial compound bacteria to ferment for 24 hours, and take plate and frame filter to pass through a 0.25mm mesh to obtain qualified fermented juice .

[0030] The filter residue after pressure filtration and unqualified rotten fr...

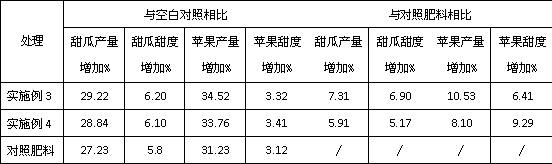

Embodiment 3

[0034] 1. Preparation of fermented fruit juice: Select fruits with qualified certificates of pesticide residue survey. The definition of fruits in the present invention includes but not limited to apples, peaches, pears, plums, apricots, kiwis, oranges, pineapples and other fruits. 5% qualified fruit, and the fruit with rotten fruit rate ≥ 5% is detected as unqualified rotten fruit. Use a crusher to crush the qualified fruit into a pulp and juice mixture with a particle size of 3-6mm, add compound enzymes, control the temperature at 50-70°C, control the stirring speed at 20-30rad / min, and enzymatically hydrolyze for 2 hours. Control the temperature of the enzymatically hydrolyzed material at 30-35°C, rotate at 50 rad / min, adjust the pH to 6-7, add beneficial compound bacteria to ferment for 24 hours, and take plate and frame filter to pass through a 0.25mm mesh to obtain qualified fermented juice .

[0035] The filter residue after pressure filtration and unqualified rotten f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com