Water source safety prevention and control device for floating nuclear power plant

A technology for nuclear power plants and monitoring devices, which is used in nuclear power plant auxiliary equipment, nuclear power generation, sterilization/microdynamic water/sewage treatment, etc., to ensure safe and normal operation, less environmental pollution, and simple installation and maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

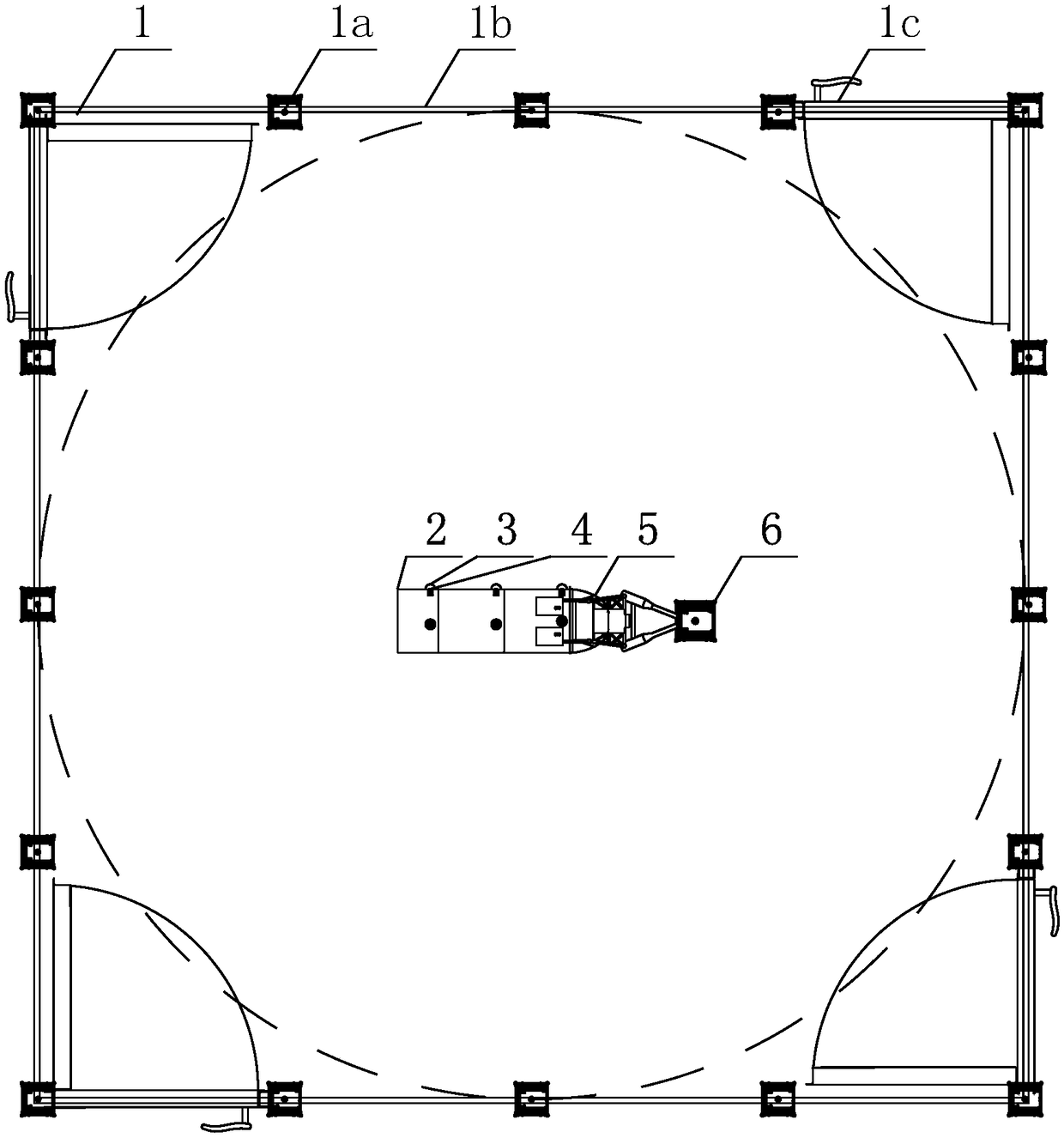

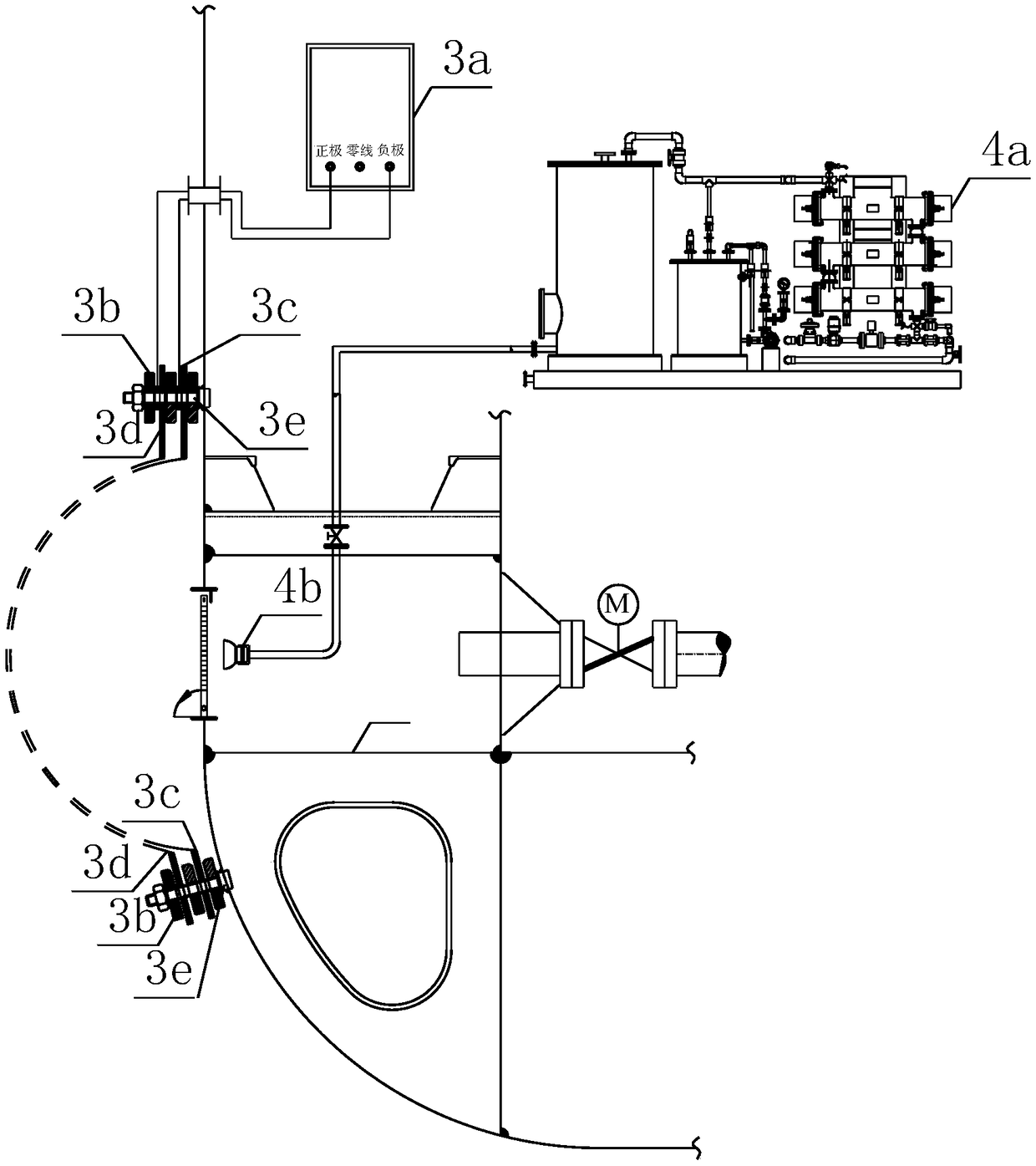

[0031] see figure 1 As shown, the water source safety prevention and control device for a floating nuclear power plant in the embodiment of the present invention includes a primary prevention and control component 1 located on the periphery of the floating nuclear power plant 5, and a secondary prevention and control component located around the water intake of the water tank 2 of the floating nuclear power plant 5 Component 3.

[0032] see figure 1 As shown, the first-level prevention and control component 1 includes a number of base towers 1a arranged on the periphery of the floating nuclear power plant 5 and connected to form a closed figure. seawater corrosion resistant material).

[0033] It can be seen that the present invention provides primary protection on the periphery of the floating nuclear power plant 5 through the primary prev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com