A method for fully burning and incinerating garbage

A technology of full combustion and garbage, applied in the combustion method, incinerator, combustion type, etc., can solve the problems of small flame contact area, uneven distribution of solid waste, air pollution by exhaust gas, etc., to reduce the incineration temperature and the incineration time. , the effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

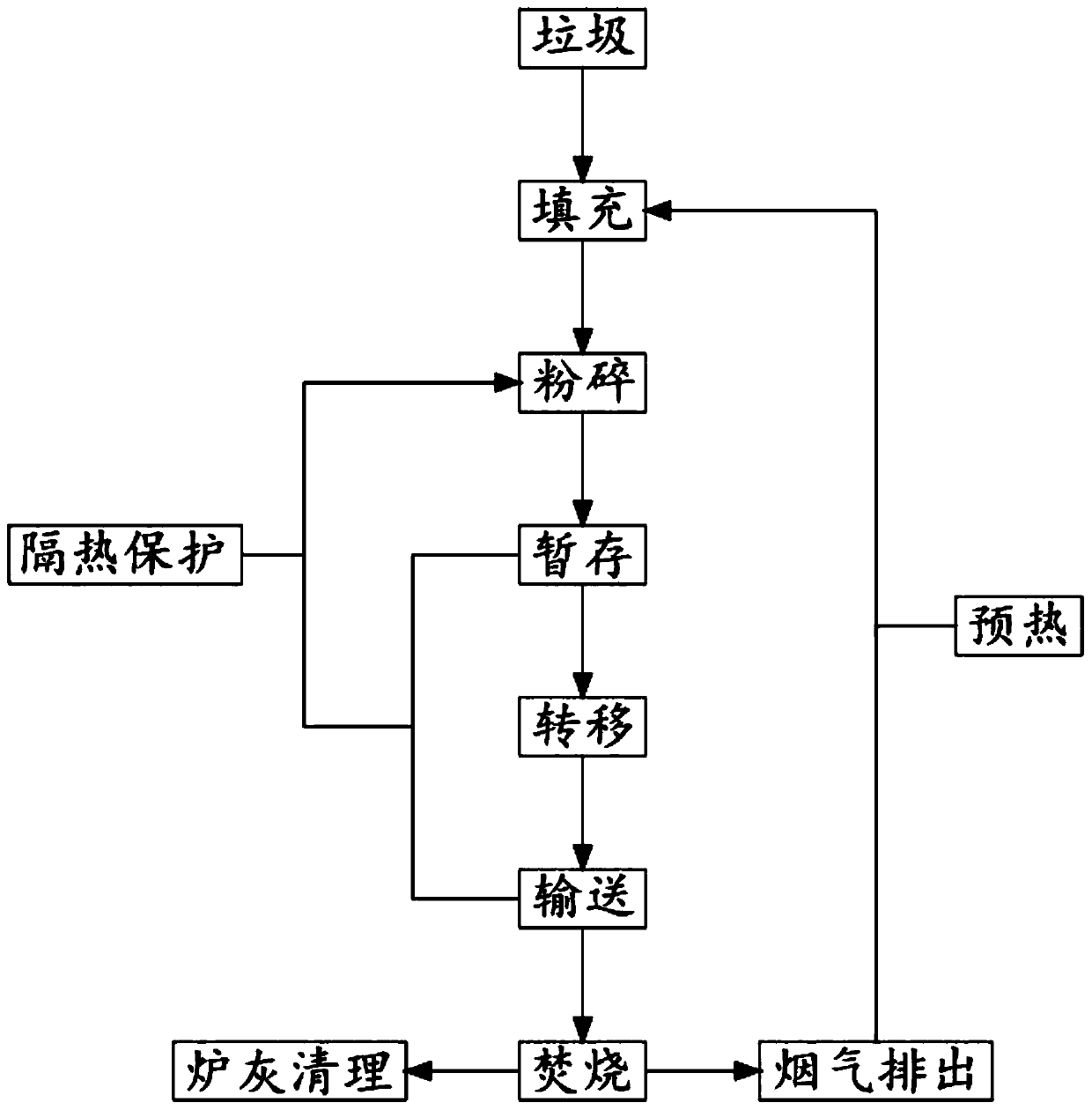

[0047] Such as figure 1 Shown, a kind of rubbish fully burns the incineration method, comprises the following steps:

[0048] Step 1, garbage filling, transporting the collected garbage into the storage area 10;

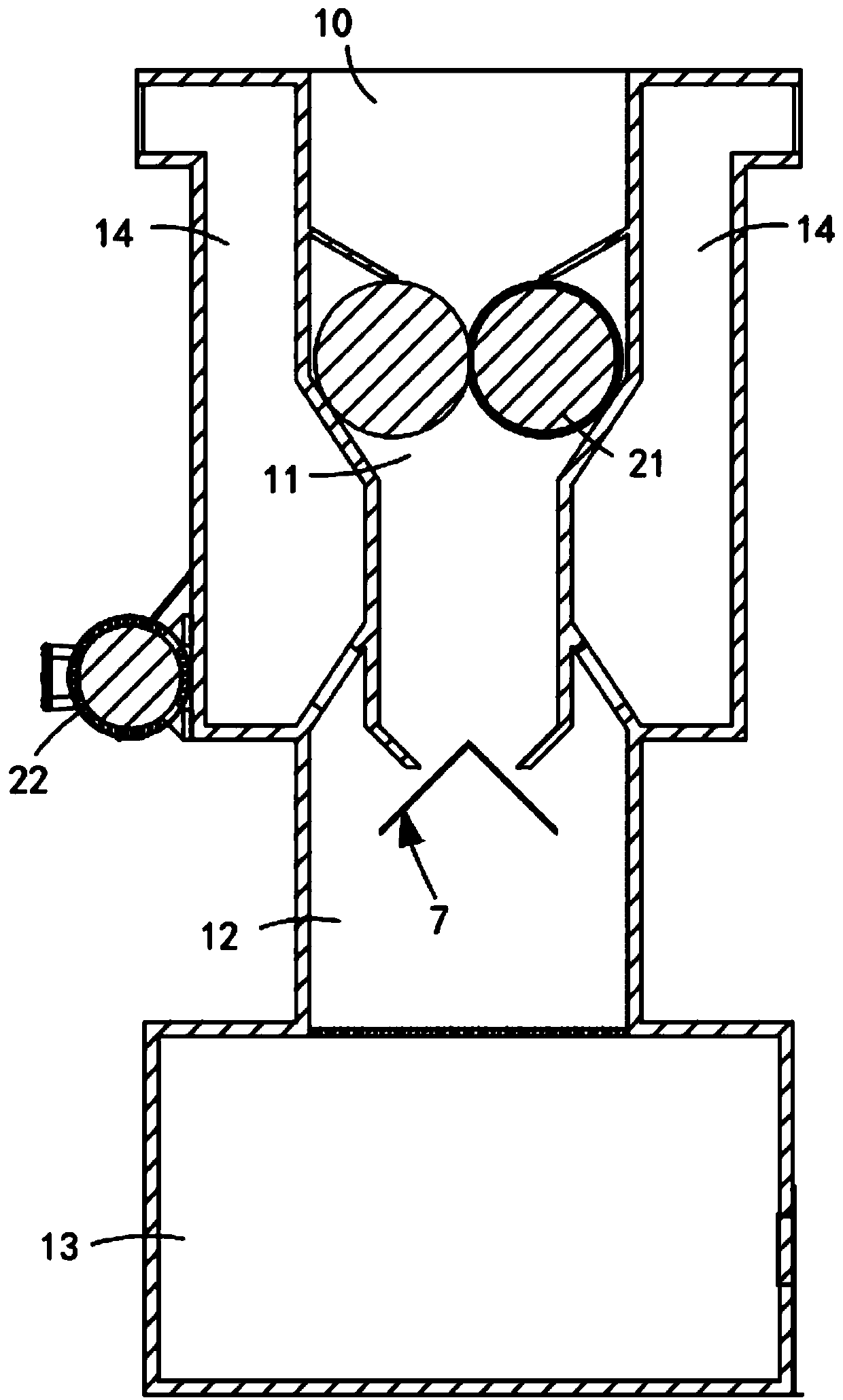

[0049] Step 2, rubbish crushing, the rubbish transported into the storage area 10 falls vertically downwards to the crushing station located below the storage area 10, and the first crushing roller 211 and the second crushing roller 212 are bitten, cut and crushed ;

[0050]Step 3, temporarily storing crushed garbage. The crushed garbage falls vertically at the temporary storage station directly below the first crushing roller 211 and the second crushing roller 212, and is accumulated and stored on the closed first partition door 511 ;

[0051] Step 4, garbage transfer, the first partition door 511 is opened, and the garbage stored thereon is transferred vertically downward to the closed second partition door 611 located below the first partition door 511;

[005...

Embodiment approach

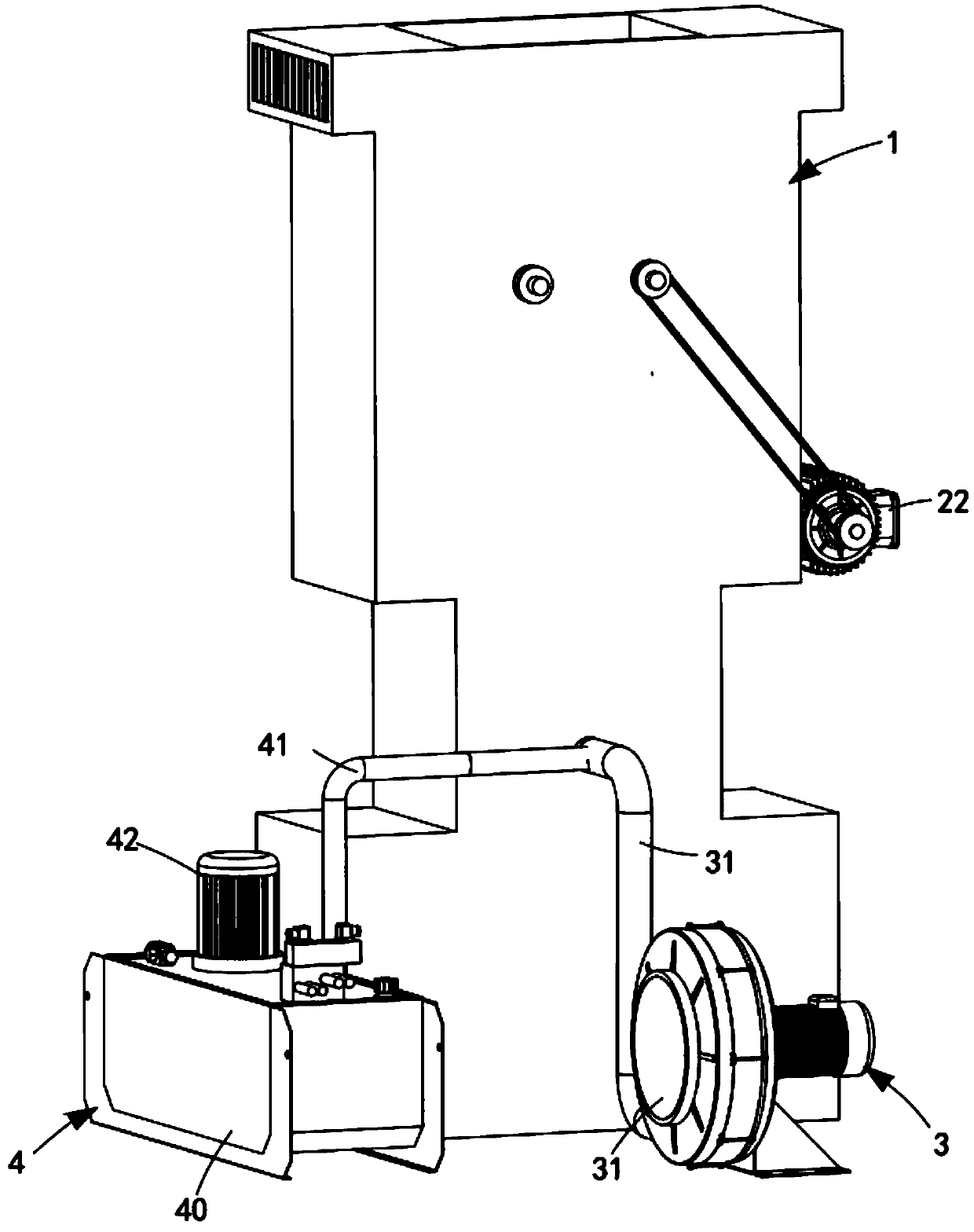

[0075] Such as Figure 4 As shown, as a preferred embodiment, the drive assembly 22 includes:

[0076] A drive motor 221, the drive motor 221 is fixedly arranged on the outer wall of the furnace body 1, and is connected to the first pulverizing roller 211 through a belt drive;

[0077] A driving gear 222, the driving gear 222 is sleeved on one side of the first crushing roller 211; and

[0078] The driven gear 223 , the driven gear 223 is sheathed on the second crushing roller 212 , and is engaged with the driving gear 222 for transmission.

[0079] It should be noted here that the driving motor 221 works, the driving gear 222 rotates, and drives the driven gear 223 for transmission. At the same time, the driving gear 222 drives the first crushing roller 211 to rotate, and the driven gear 223 drives the second crushing roller 212 to rotate. The rotation of the first crushing roller 211 and the second crushing roller 212, the respective first crushing blades 2111 and the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com