Desulfurization waste water evaporator with inert carrier circling and method

A technology of desulfurization wastewater and inert carrier, which is applied in gaseous discharge wastewater treatment, heating water/sewage treatment, etc., can solve the problems of reduced production capacity, high power consumption, high labor intensity, etc., so as to reduce the treatment cost and reduce the amount of waste liquid. , the effect of prolonging life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

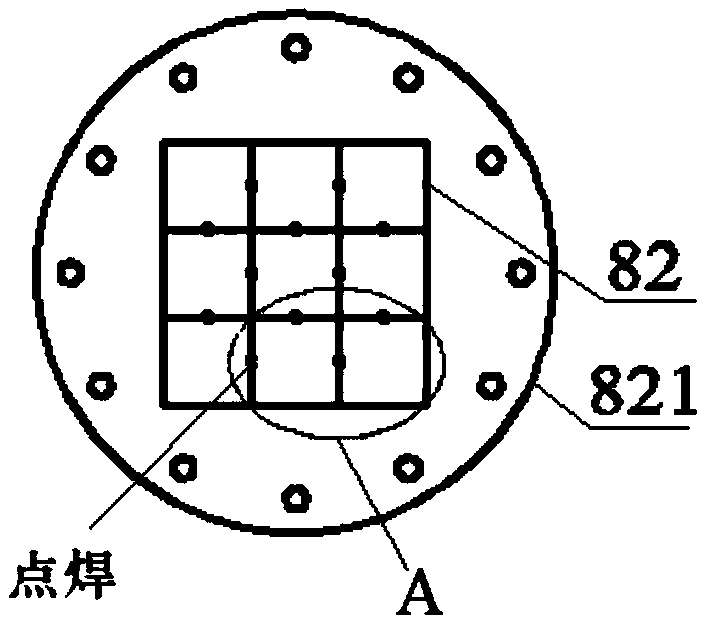

[0043] A desulfurization wastewater evaporator with inert carrier circulation, the evaporator is composed of a heater 8, a venturi tube 13 connected to the material inlet 5 arranged above the heater 8, and a material outlet arranged below the heater 8 10 connected to the solid-liquid separator 11, the gas-liquid separator 1 connected to the upper liquid outlet 6 of the solid-liquid separator 11, the circulation pump 12 connected to the gas-liquid separator 1 and the Venturi tube 13, solid The bottom of the liquid separator 11 is connected to the throat of the Venturi tube 13, a density meter 15 is provided on one side of the gas-liquid separator 1, a liquid level gauge 16 is connected to the other side, a circulating water outlet 19 is also provided on the side, and a circulating water outlet 19 is provided on the lower side. There is a concentrated liquid regulating valve 17; the circulating pipe connected to the circulating water outlet 19 merges with the outlet of the desulf...

Embodiment 2

[0049] A desulfurization wastewater evaporator with inert carrier circulation, the evaporator is composed of a heater 8, a star unloader 14 connected to the material inlet 5 arranged above the heater 8, and a discharge outlet arranged below the heater 8 A solid-liquid separator 11 connected to the port 10, a gas-liquid separator 1 connected to the upper liquid outlet 6 of the solid-liquid separator 11, a circulation pump 12 connected to the gas-liquid separator 1 and a star unloader 14 , the bottom of the solid-liquid separator 11 is connected to the solid inlet of the star unloader 14, the gas-liquid separator 1 is provided with a density meter 15 on one side, a liquid level gauge 16 on the other side, and a circulating water outlet 19 on the side , the bottom is provided with a concentrated liquid regulating valve 17; the circulating pipe connected to the circulating water outlet 19 and the outlet of the desulfurization waste water pipe are connected together to the inlet of ...

Embodiment 3

[0052] A desulfurization wastewater evaporator with inert carrier circulation, the desulfurization wastewater entering the entire evaporator system process comes from the terminal wastewater of the power plant. In the heater 8 in the evaporator, the steam temperature ranges from 95 DEG C to 160 DEG C, and the steam pressure ranges from 0.085 MPa to 0.618 MPa. The solid content of the incoming desulfurization wastewater is 1-10%, and the solid content of the concentrated liquid is 20-50%. The inert carrier 4 is corundum or steel balls with a particle size of 0.1 to 1 mm, or hollow steel balls with a particle size of 0.1 to 3 mm.

[0053] Working process of the present invention is as follows:

[0054] 1) Send hot steam to the intake pipe 3, process the desulfurization wastewater discharged from the power plant so that its solid content is 1-10%, open and adjust the regulating valve 18 on the desulfurization wastewater pipe, and send the desulfurization wastewater to the inlet ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com