Multi-level anti-collision system for double-swing-shaft laser machining head

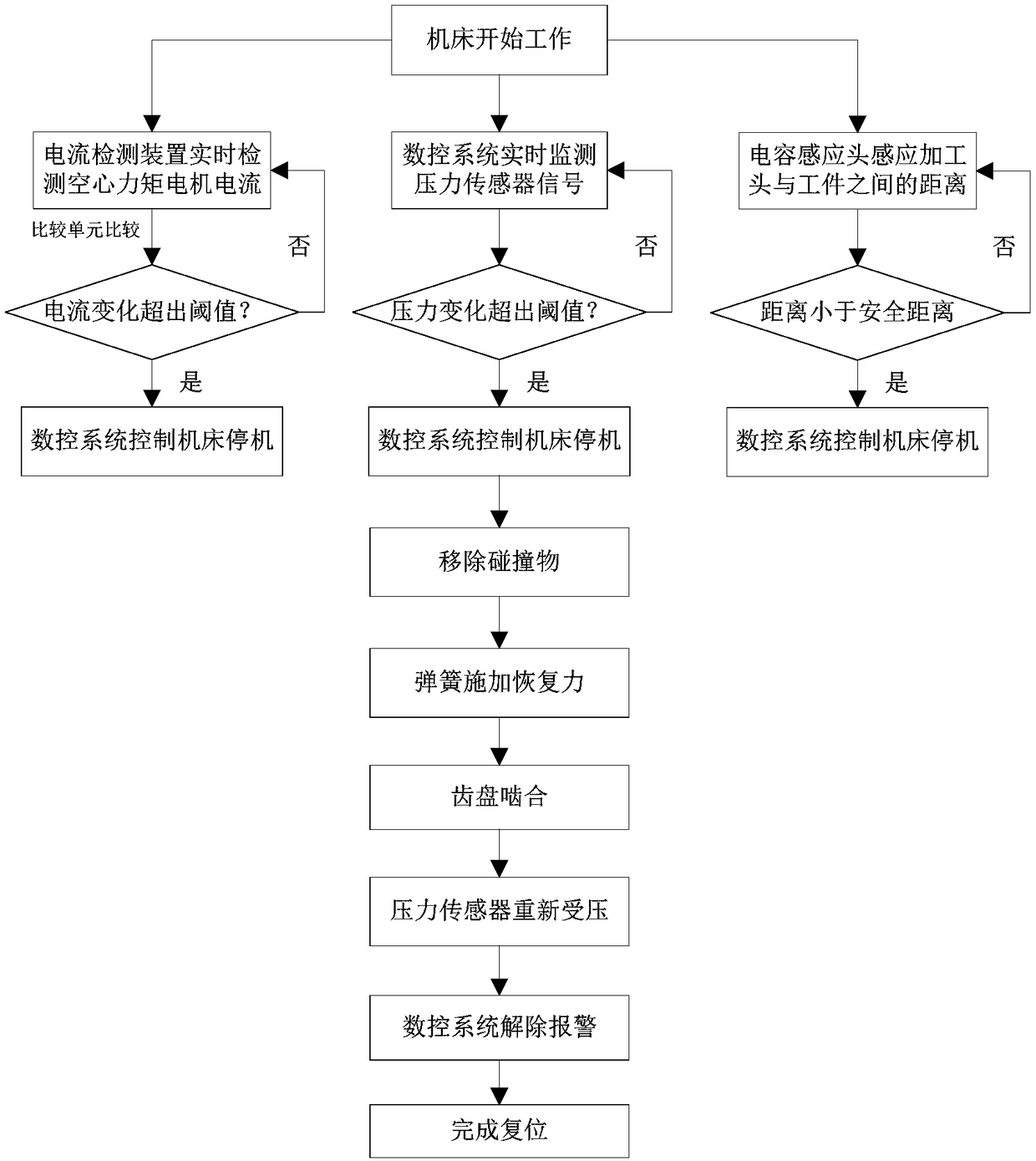

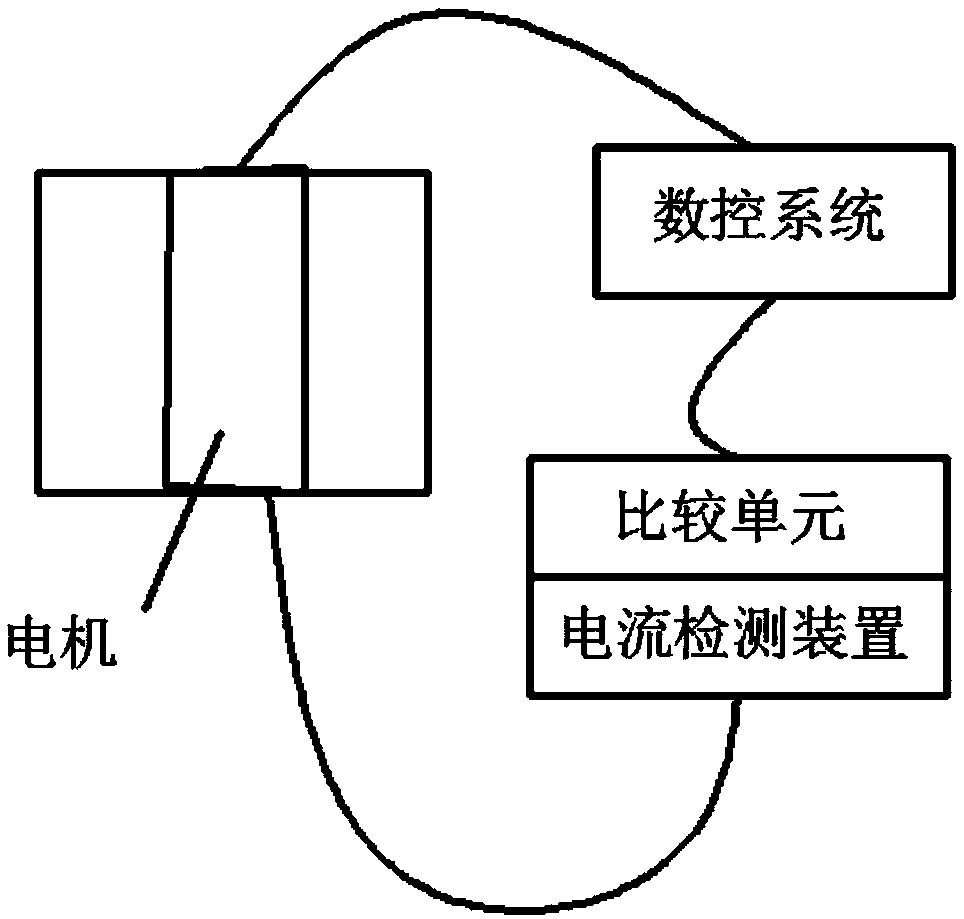

A technology of laser processing head and anti-collision system, applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of inability to achieve protection, poor anti-collision effect, ineffective anti-collision protection, etc., and achieve improved accuracy and stability, high repeat positioning accuracy, fast and accurate reset

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be described in detail below with reference to the drawings.

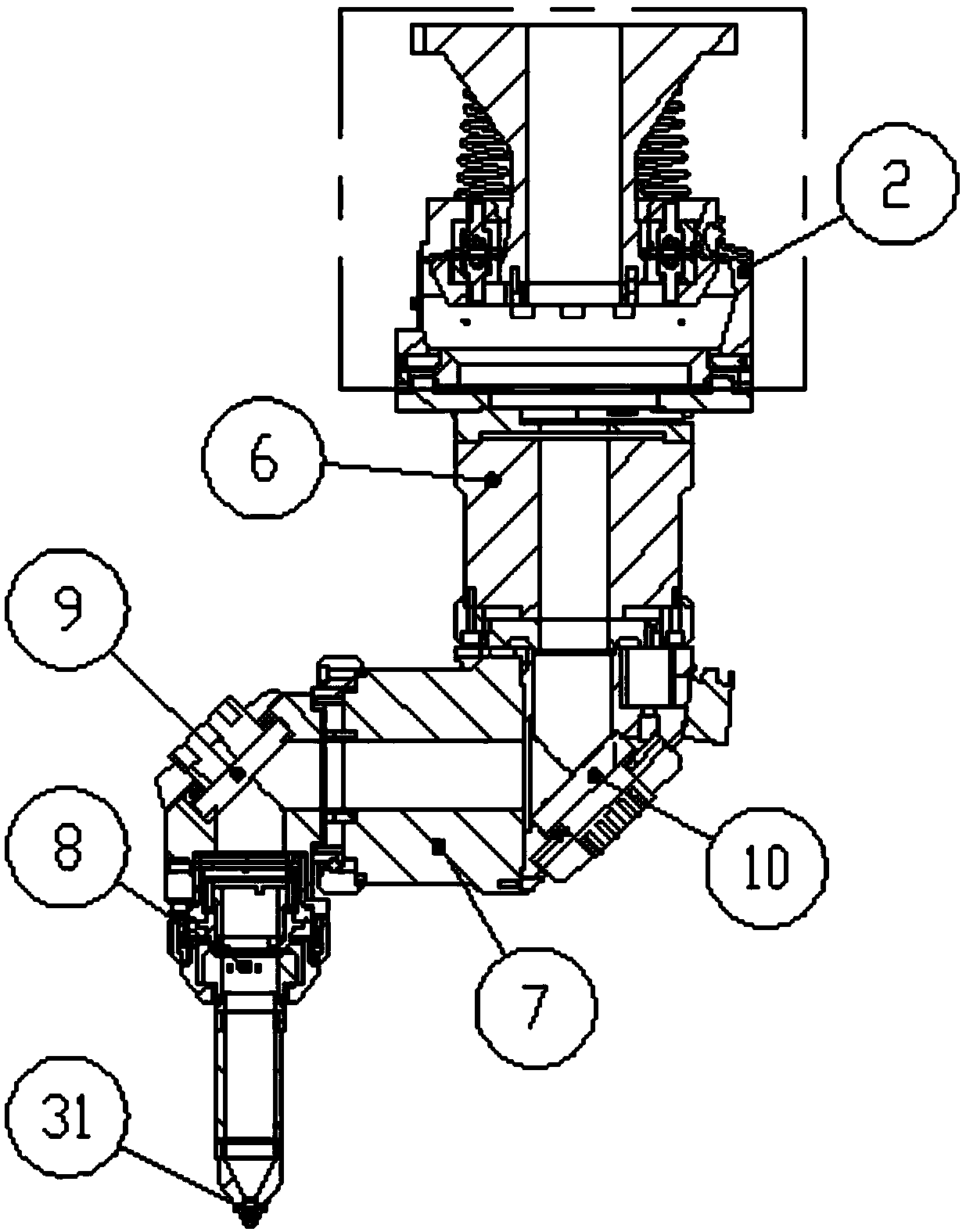

[0056] Such as figure 1 As shown, an existing dual pendulum axis laser processing head includes a first motor 6, a second motor 7, a first mirror assembly 9, a second mirror assembly 10, and a focusing assembly 8. Among them, the first motor 6 and the second motor 7 are both hollow direct drive motors, figure 1 The dual pendulum axis laser processing head shown is only an example to facilitate the subsequent description of the structure and working principle of the collision avoidance system of the present invention; in other existing dual pendulum axis laser processing heads, the first motor 6 and the second motor 7 It can also adopt the form of ordinary motor + gear transmission.

[0057] The motor rotor of the first motor 6 is fixedly connected to the incident end surface of the second reflector assembly 10, the exit end surface of the second reflector assembly 10 is fixed to the mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com