Direct-current charging gun of new energy electric automobile

An electric vehicle, DC charging technology, applied in the direction of electric vehicle charging technology, electric vehicles, charging stations, etc., can solve the problems of not installing a temperature monitoring device, not being able to completely prevent live plugging, and damage to the electrical components of the gun body, etc., to achieve convenience The effects of positive connection, labor-saving grasping, and improved safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

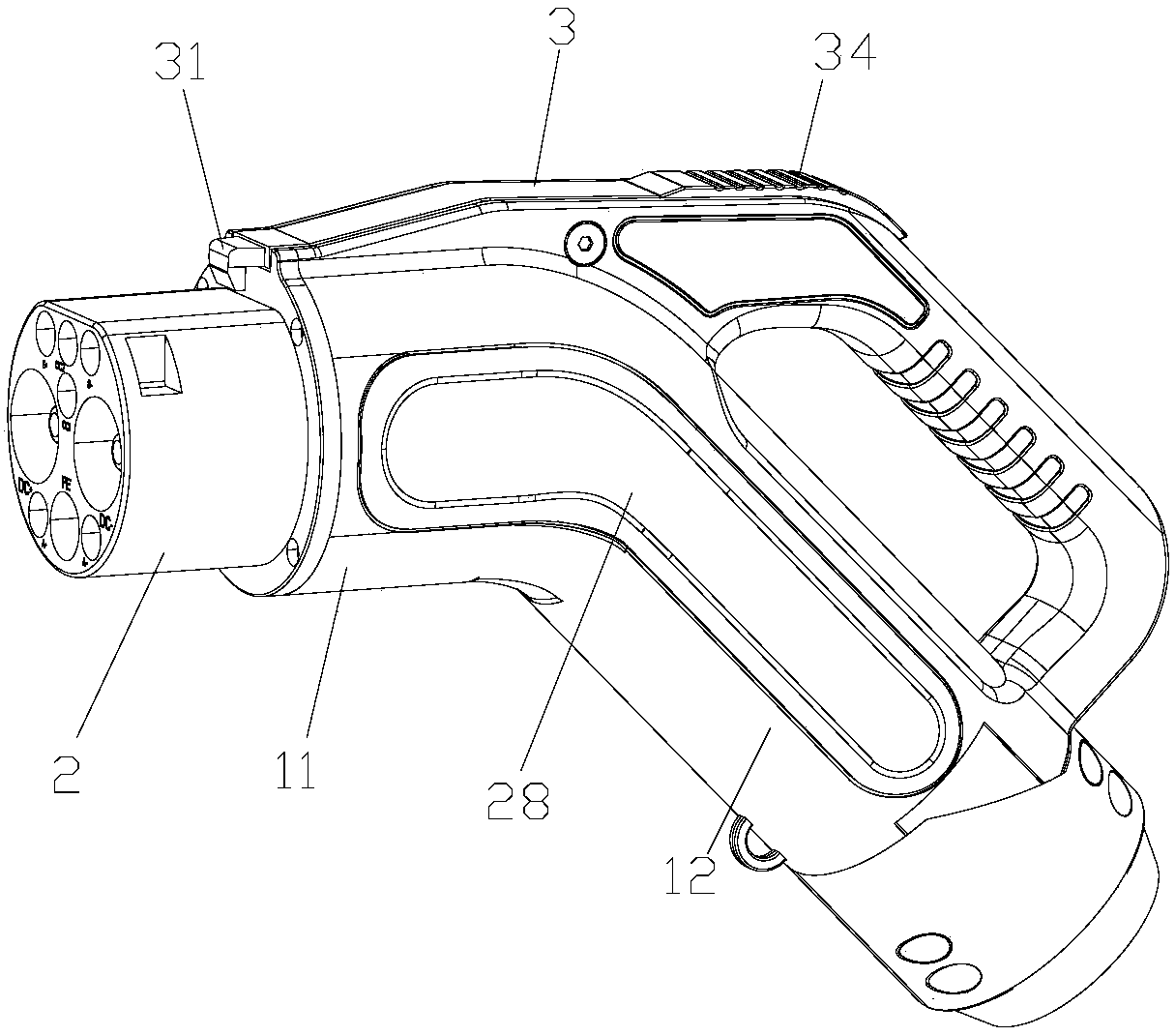

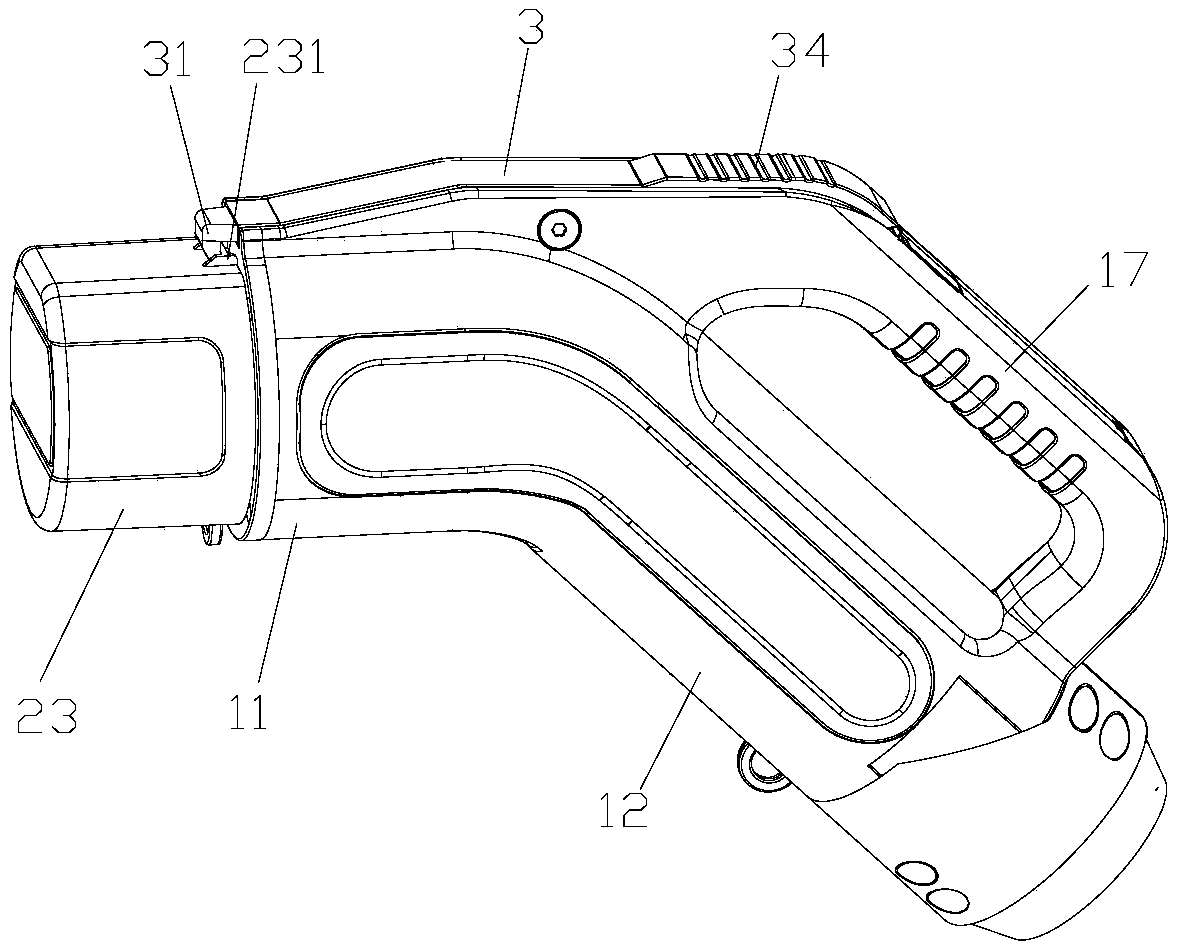

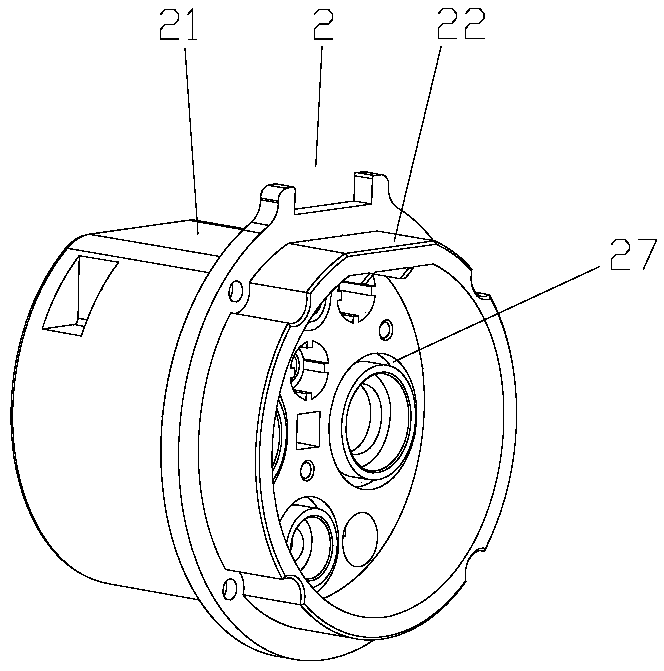

[0043] Embodiment 1: refer to Figure 1-Figure 16 , a DC charging gun for new energy electric vehicles, including a gun body 1, a charging plug 2 at the front end of the gun body 1, and a locking plate 3. The gun body is an integral injection molding structure, and the charging plug 2 is provided with a charging pin 25. The front end of 1 is the plug part 11 connected with the charging plug 2, the rear end of the gun body 1 is the connection part 12 connected with the cable, the plug part 11 is parallel to the horizontal line, and the connection part 12 is smooth from the rear end of the plug part 11 to the The rear lower side extends, the connecting part 12 and the plug part 11 form an obtuse angle of 130°, the length of the connecting part 12 is greater than the length of the plug part, and the longer length of the connecting part 12 provides sufficient space for the connection between the cable and the charging plug circuit board module Space, easy to connect, in addition, ...

Embodiment 2

[0049] Embodiment 2: The difference between this embodiment and Embodiment 1 is: in this embodiment, refer to Figure 17 , the outer wall surface of the waterproof rear ring 92 of the gun tail is a tapered surface structure, and the larger end of the tapered surface structure faces the side of the waterproof front ring of the gun tail, and contacts the cable holder through the tapered surface. After fixing, the cable holder and the gun The extrusion of the rear waterproof ring of the tail is stronger, which enhances the pressure between the waterproof rear ring of the gun tail and the cable, thereby improving the sealing performance of the place and improving the waterproof performance.

Embodiment 3

[0050] Embodiment 3: The difference between this embodiment and Embodiment 1 is: in this embodiment, refer to Figure 18 , the front end of the gun head waterproof ring 4 is provided with an annular protrusion 41 embedded in the step surface fit, the cross section of the annular protrusion 41 is an isosceles trapezoid, and the smaller end of the annular protrusion 41 is connected to the front end of the gun head waterproof ring , after the charging plug is connected to the plug part, the waterproof ring 4 of the tip of the gun will lean against the joint surface to further seal the joint surface and improve the waterproof effect. Cooperating with the groove, the annular protrusion 41 seals the joint surface of the waterproof ring 4 of the gun head and the charging plug. sex, tightness,

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com