Device and method for testing mechanical property of soil which is improved through electrochemistry under action of dry-wet cycle

A technology of dry-wet cycle and mechanical properties, which is applied in the direction of measuring devices, using repeated force/pulsation force to test the strength and strength properties of materials, etc., can solve the problems of inaccuracy, single simulation state, and inability to quantitatively control soil humidity, etc. Achieve the effect of avoiding repeated disassembly and assembly, avoiding electric corrosion and preventing flattening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

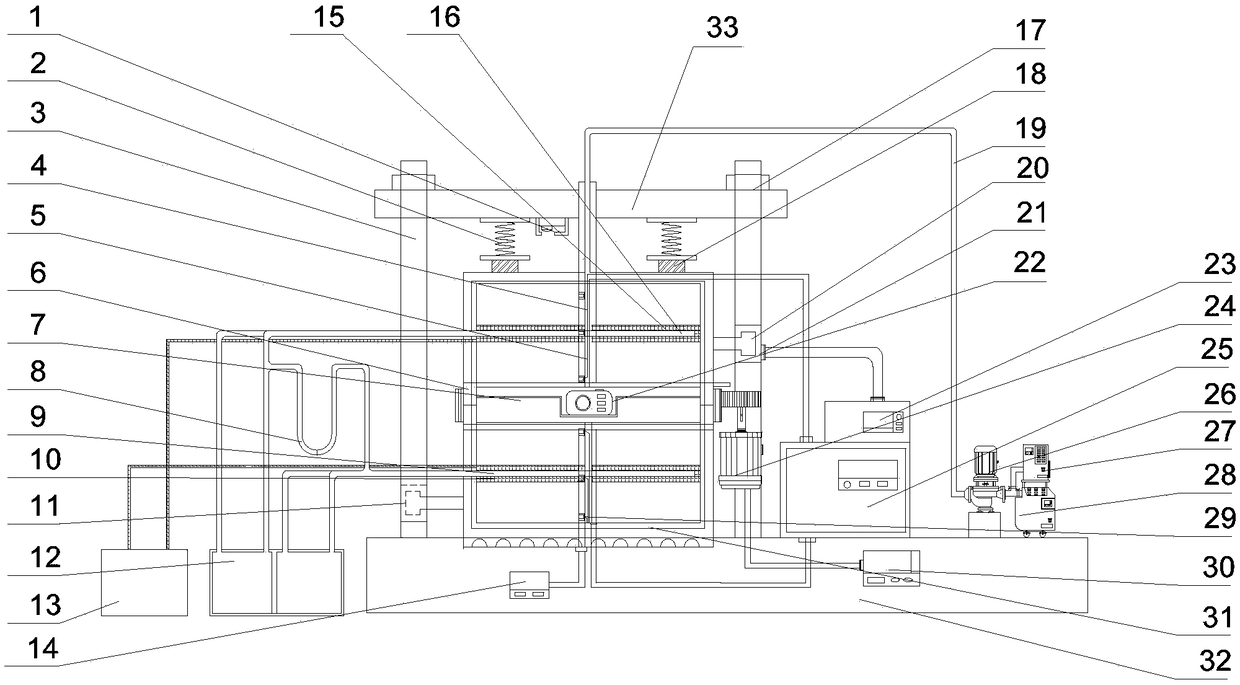

[0047] Embodiment 1, a mechanical property testing device of electrochemically improved soil under the action of dry-wet cycle, including a shear system, an electrolysis system, a dry-humidity control system, a stress application system and a stress-strain monitoring system, such as figure 1 As shown, specifically:

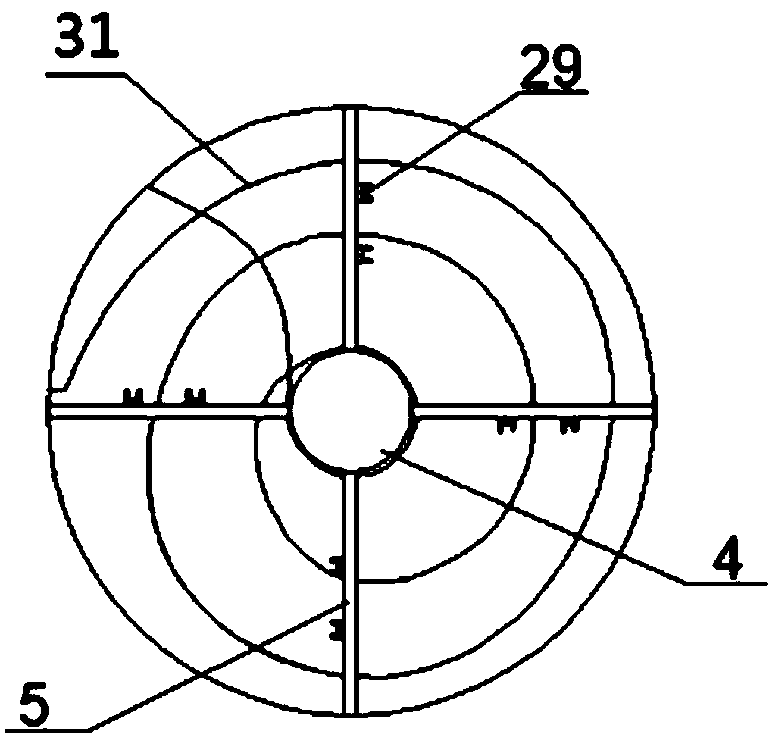

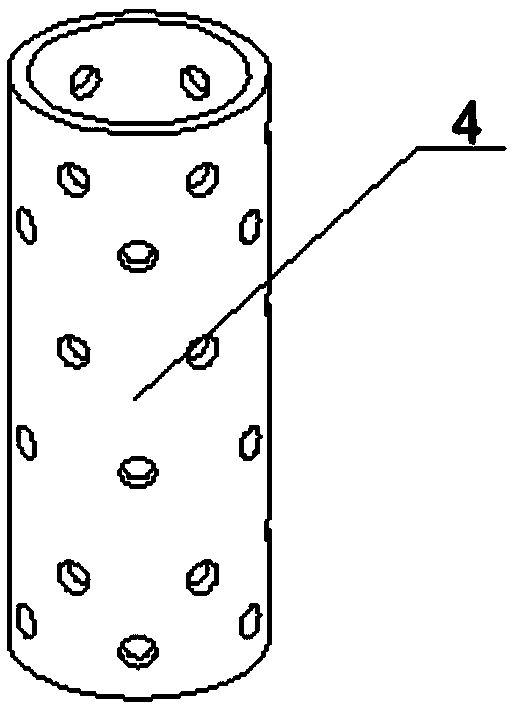

[0048] The shearing system includes a base 32 and a steel frame 3 arranged on the base 32, an axial load plate 33 is arranged on the top of the steel frame 3, and the axial load plate 33 is connected to the steel frame 3 through an axial bolt 17 The base 32 is provided with a cylindrical shearing box 6, the top of the shearing box 6 is provided with an end cover, and the soil sample is arranged in the shearing box 6, and the shearing box 6 includes an upper section shearing box, a middle section shearing box and the lower section of the shear box, the three sections of the shear box are designed independently, and each section of the shear box is in contact; the u...

Embodiment 2

[0057] Embodiment 2, based on the test device described in Embodiment 1, this embodiment discloses a test method based on a test device for mechanical properties of electrochemically improved soil under the action of a dry-wet cycle, comprising the following steps:

[0058](1), layering the soil configured according to the design water content is placed in the shear box 6, and compacted layer by layer; and the degree of compaction is controlled by the dry density (the ratio of the sample dry density to the maximum dry density is degree of compaction), scrape between layers of soil to avoid stratification of soil;

[0059] (2) By tightening the axial pressure bolt 17, observe the reading of the first pressure sensor 18 until the reading of the first pressure sensor reaches the set axial pressure and stop to ensure that the entire dry-wet cycle process and the shearing process are in the normal direction. completed under stiffness;

[0060] (3), according to the mensuration to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com