Method for simulating fatigue test of inter-pole connection wire

A technology of connecting wires between poles and a simulation method, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., and can solve problems affecting the safety of the unit, the structure of the connecting wire between the poles, the mechanical load of the structure, the fatigue life of the connecting wire between the poles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] A method for simulating a fatigue test of an inter-pole connecting line, the method comprising the steps of:

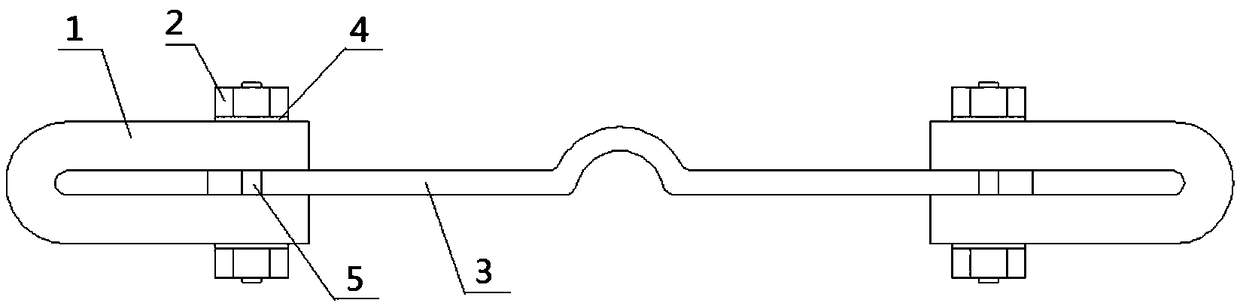

[0018] (a) Connection and assembly of the inter-pole connecting wire 3: Set the inter-pole connecting wire 3 with the jacket 1, and fix it with the double-ended stud 5, the nut 2 and the washer 4, and apply the double-ended stud 5 Preload F 0 , F 0 =0.5Aσ S ,σ S : double-ended stud material yield limit, A: double-ended stud stress cross-sectional area;

[0019] (b) Thermal fatigue test of the connecting wire 3 between poles: According to the ambient temperature and self-heating conditions when the hydro-generator is in stable operation, the connecting wire 3 between the poles is heated by winding resistance wire to accurately simulate its real thermal stress in the operating state, and at the same time observe the temperature of the inter-electrode connecting line 3 with an infrared thermometer;

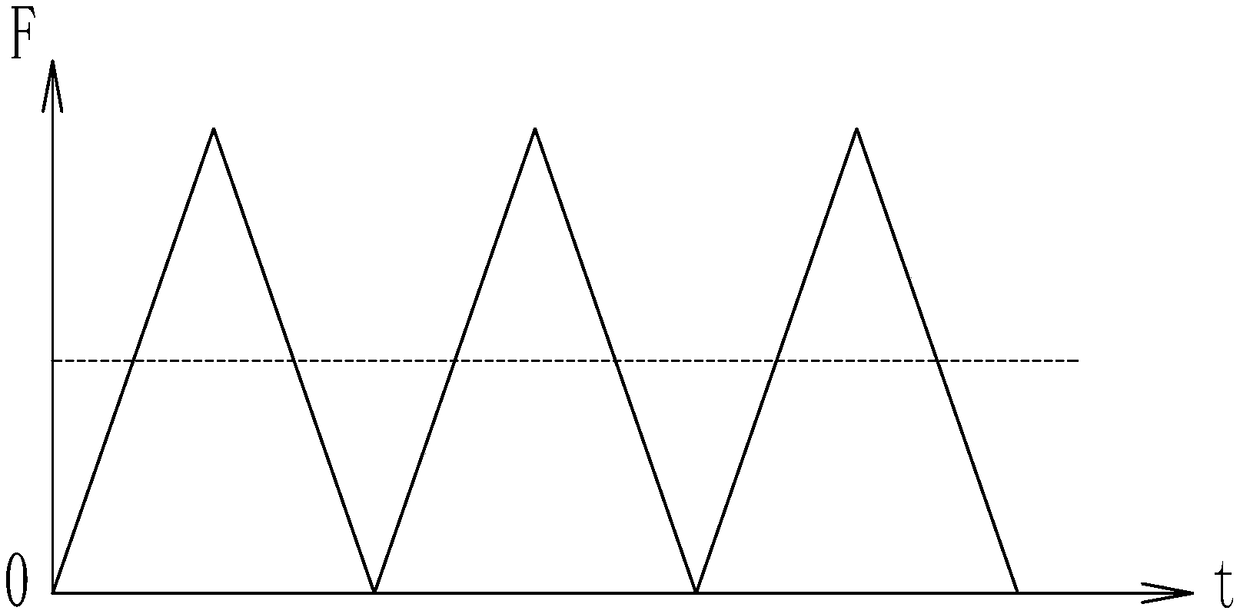

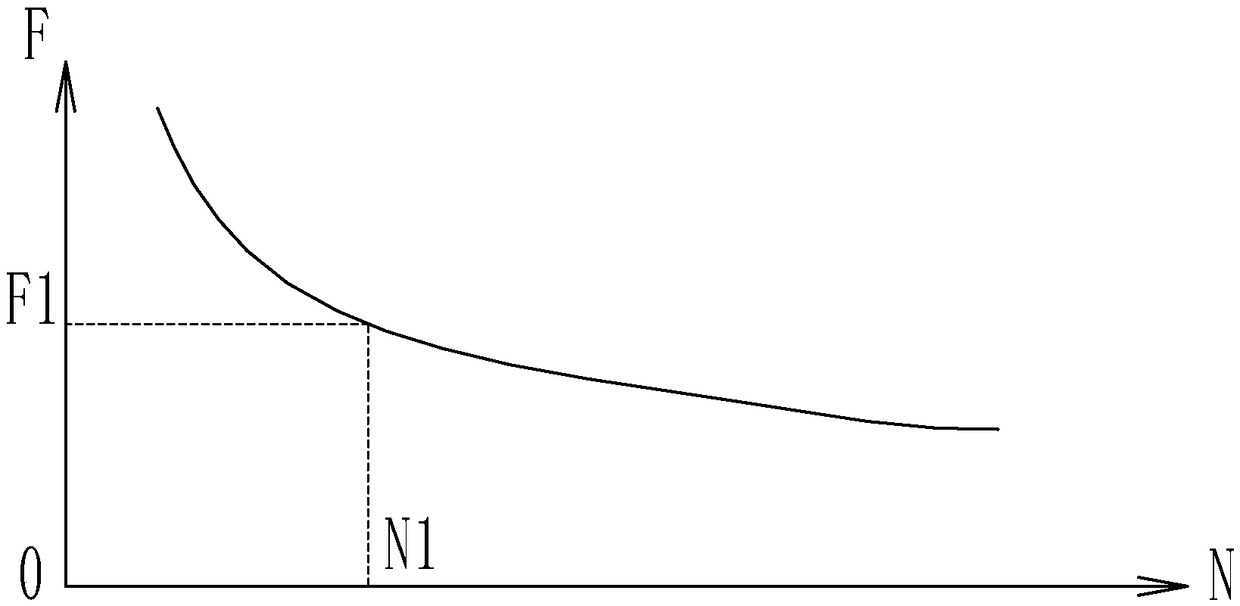

[0020] (c) Loading test of the assembly of the inter-electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com