Pipeline smoke heating device

A flue gas heating and heating device technology, which is applied in the field of flue gas heating, can solve problems such as separate configuration, and achieve the effects of reasonable flame length, flame protection, and pipe wall protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

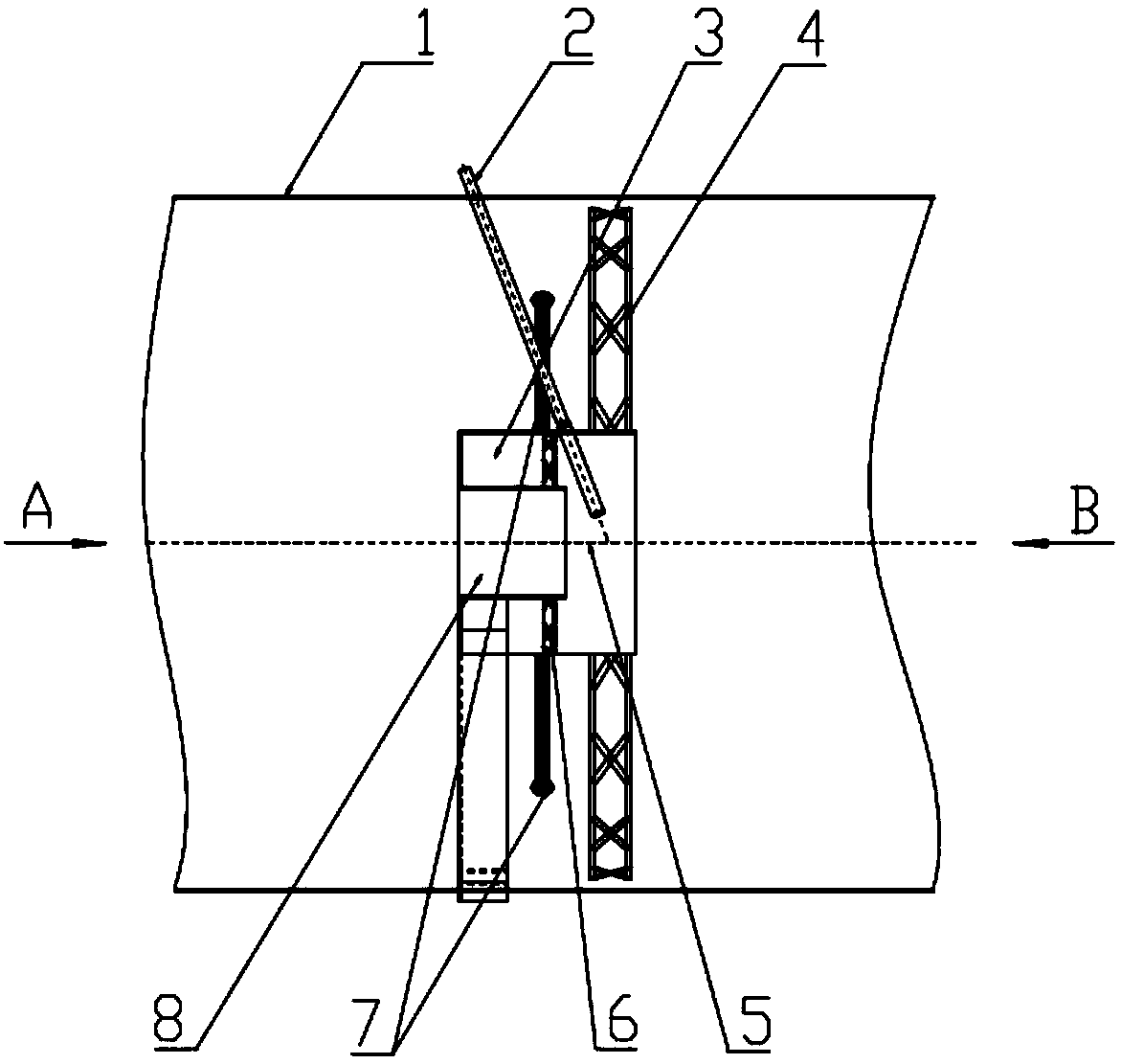

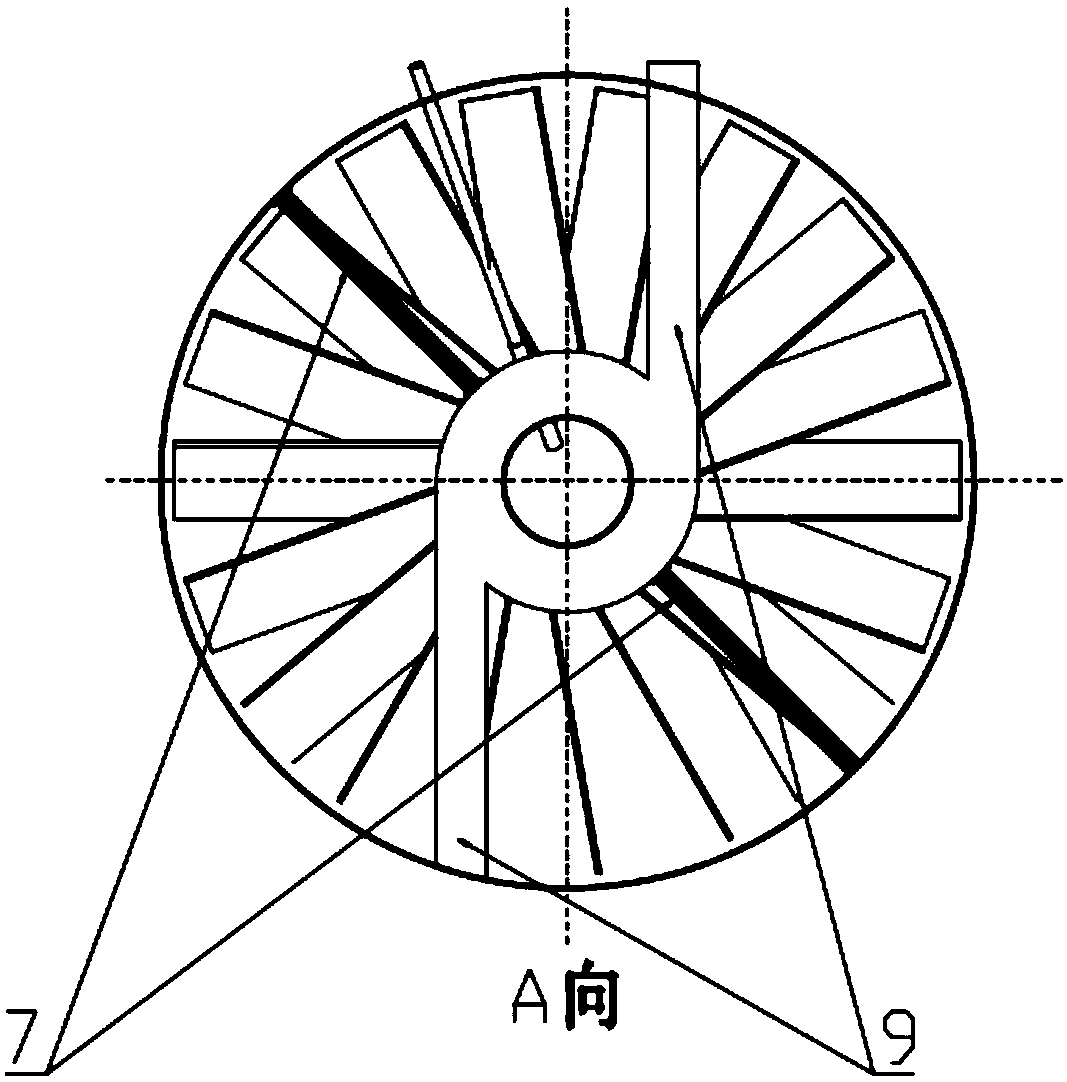

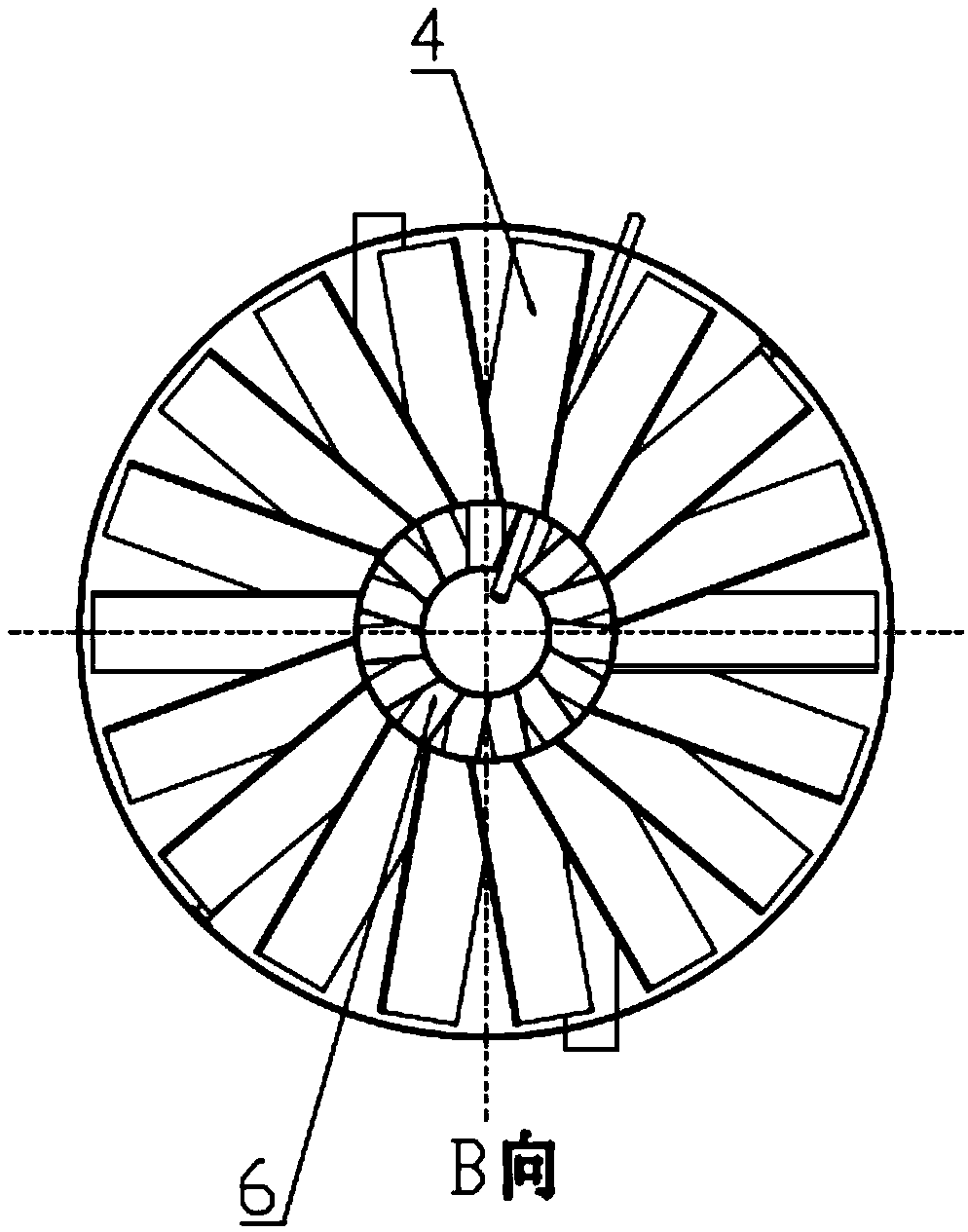

[0030] Such as Figure 1-3 As shown, the present invention provides a pipeline flue gas heating device. The heating device is fixed in the flue 1 and includes a secondary flue gas channel 10 coaxially arranged in sequence from outside to inside, a gas swirl chamber 3 and a central wind 8, the channel wall of the secondary flue gas channel 10 is fixedly connected with the flue wall of the flue 1, and an inclined gas swirl vane 6 is arranged between the outer wall of the outlet of the central air duct 8 and the inner wall of the gas swirl chamber 3 , the gas swirl blade 6 and the central air duct 8 front end form a combustion chamber 5, and the rear end forms a gas swirl chamber 3, the gas pipeline 9 communicates with the gas swirl chamber 3 to feed gas, and the ignition gun 2 passes through each outer layer The wall surface is inserted into the combustion chamber 5, and several layers of inclined smoke swirl vanes 4 are arranged between the outer wall of the coal gas swirl cham...

Embodiment 2

[0037] Such as Figure 4-5As shown, the difference between the second embodiment and the first embodiment is that there are multiple layers of secondary flue gas passages 10 in the second embodiment, and flue gas swirl vanes 4 are arranged between each layer of secondary flue gas passages 10 . The number of layers of the secondary flue gas channel 10 can be designed according to the diameter of the flue.

[0038] Working principle of the present invention: In the present invention, the gas is input into the gas swirl cavity 3 through the gas pipeline 9, and the gas forms a whirlwind in the gas swirl cavity 3, and the flue gas in the gas swirl blade 6 and the central air duct 8 Premixing is carried out, the premixed gas flows into the combustion chamber 5, and is ignited by the ignition gun 2 in the combustion chamber 5; at the exit of the secondary flue gas channel 10, the flue gas swirl blade 4 with the opposite direction is arranged. If there are multiple layers of secondary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com