Oil supply device and method of bearing

A bearing oil supply and bearing technology, which is applied to components of pumping devices for elastic fluids, non-variable pumps, machines/engines, etc., can solve problems that cannot be specific to bearings, and reduce frictional power Effect of loss and waste reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

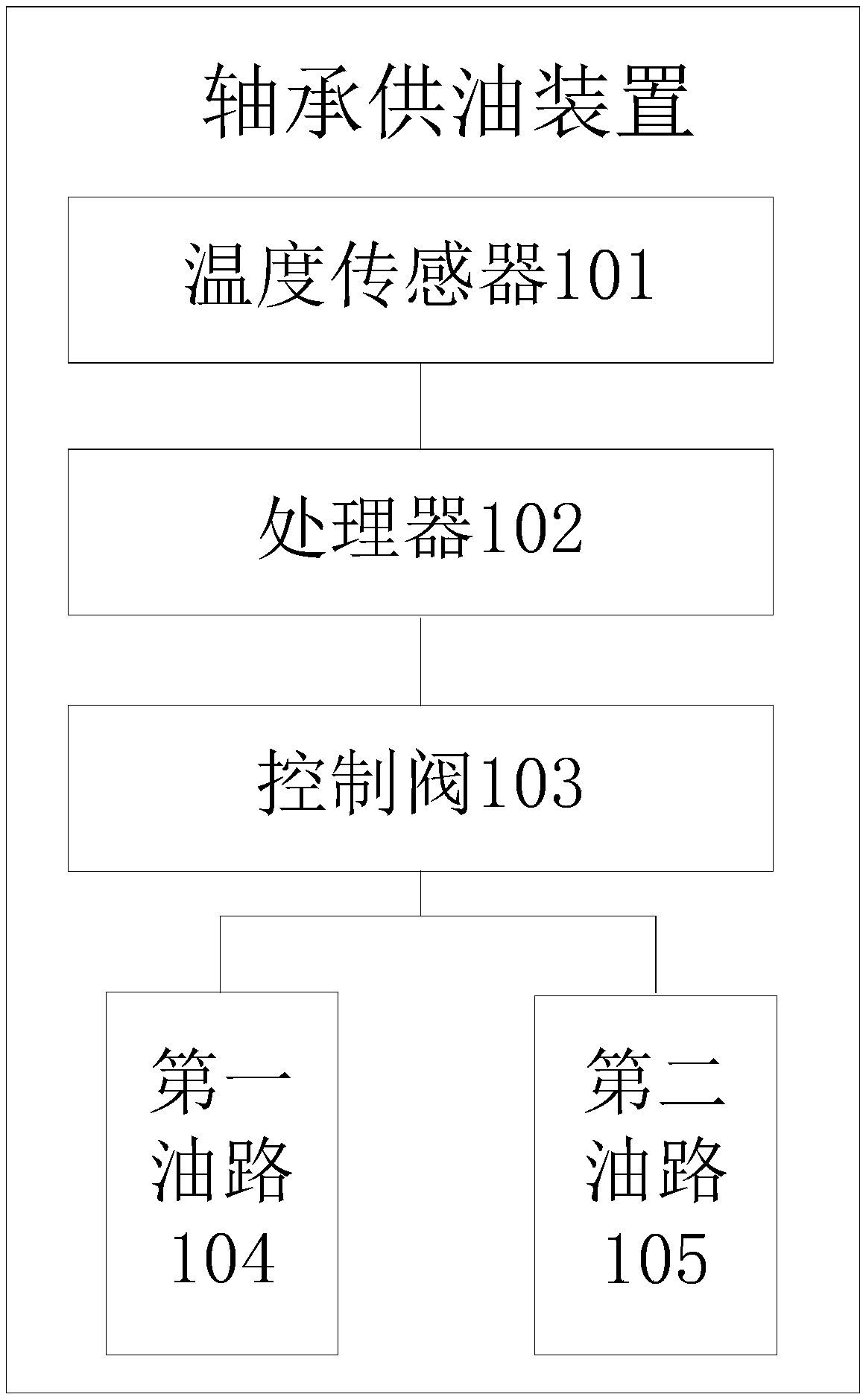

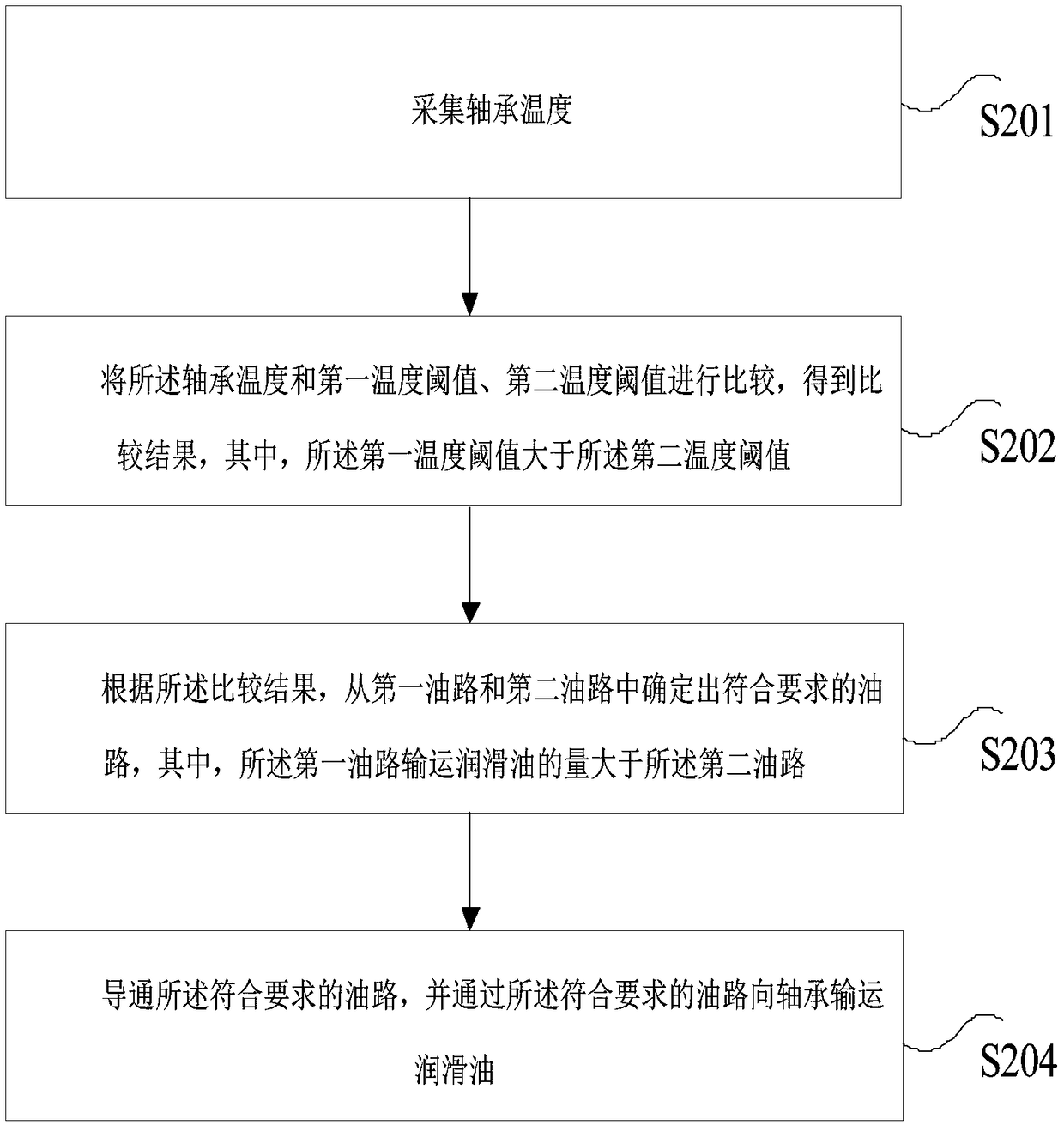

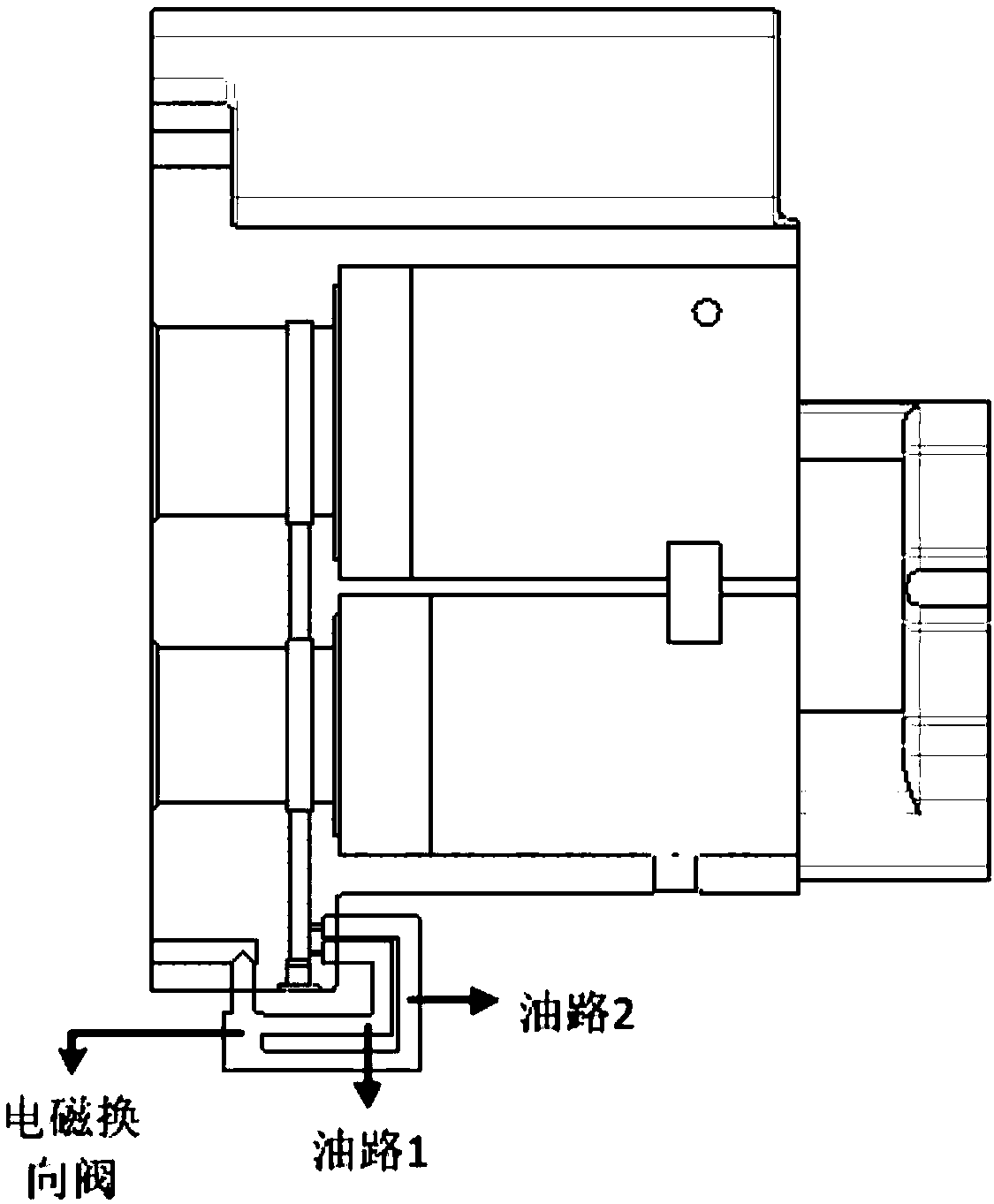

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the objectives, technical solutions, and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the embodiments and the drawings. Here, the exemplary embodiments of the present invention and the description thereof are used to explain the present invention, but not as a limitation to the present invention.

[0027] Considering that the existing methods are often only considering that the bearing temperature can be reduced by transporting lubricating oil to the bearing to ensure the normal operation of the bearing. However, during the specific implementation, no specific consideration was given to how to reasonably adjust the amount of lubricating oil transported to the bearing, so that the lubricating oil provided to the bearing maintains a reasonable amount and reduces the increase in frictional power loss caused by excessive lubricating oil . Therefore, when the existing methods a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com