High-maintainability integrated centrifugal fan set

A ventilator unit and maintainable technology, applied to liquid fuel engines, components of pumping devices for elastic fluids, electromechanical devices, etc., can solve problems such as time-consuming and inconvenient installation, and reduce work intensity and requirements , the effect of reducing the volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

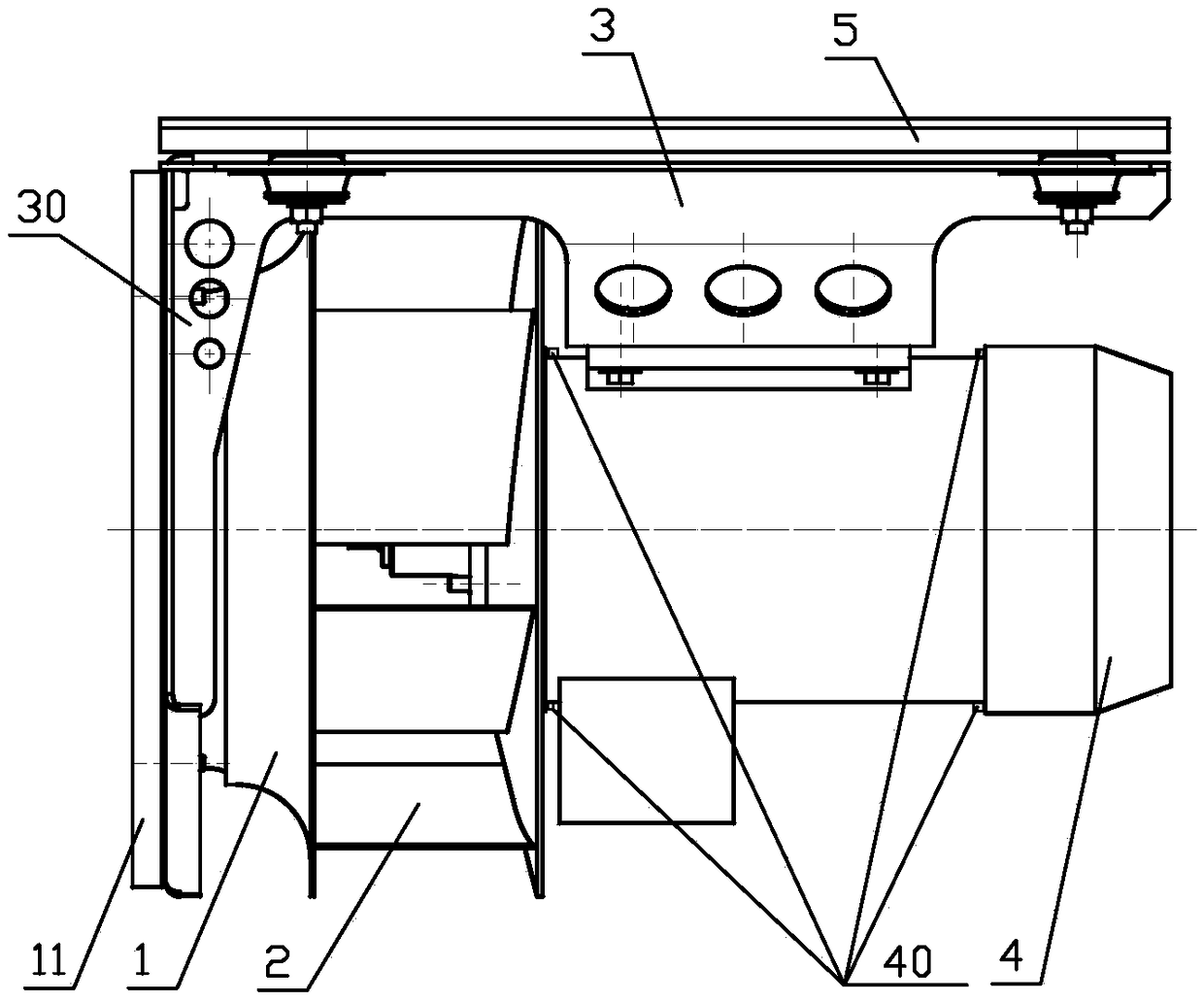

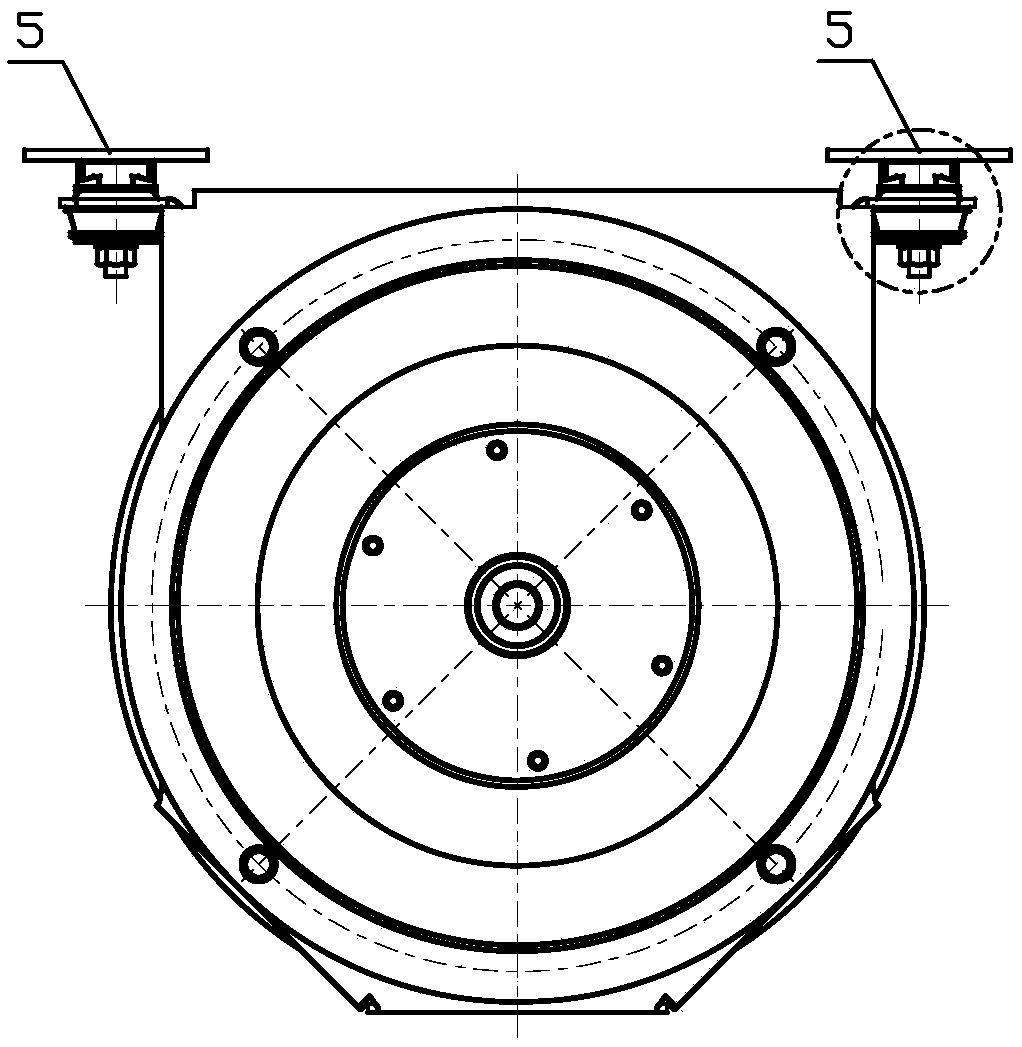

[0027] Such as figure 1 with figure 2 Shown is a high-maintenance integrated centrifugal fan unit disclosed by the present invention, including a collector 1, a centrifugal impeller 2, a mounting frame 3 and a motor 4, the motor 4 is fixed on the mounting frame 3, and the centrifugal impeller 2 is installed On the output shaft 41 of the motor 4, the current collector 1 is fixed on the mounting frame 3 and placed at the front end of the centrifugal impeller 2, and also includes a slide rail 5 and a T-bolt 6, and the slide rail 5 is provided with a A T-shaped chute 50 extending in the longitudinal direction, and the installation frame 3 is installed in the T-shaped chute 50 through T-shaped bolts 6 . The slide rail 5 is fixed on the bottom mounting beam of the vehicle by bolts.

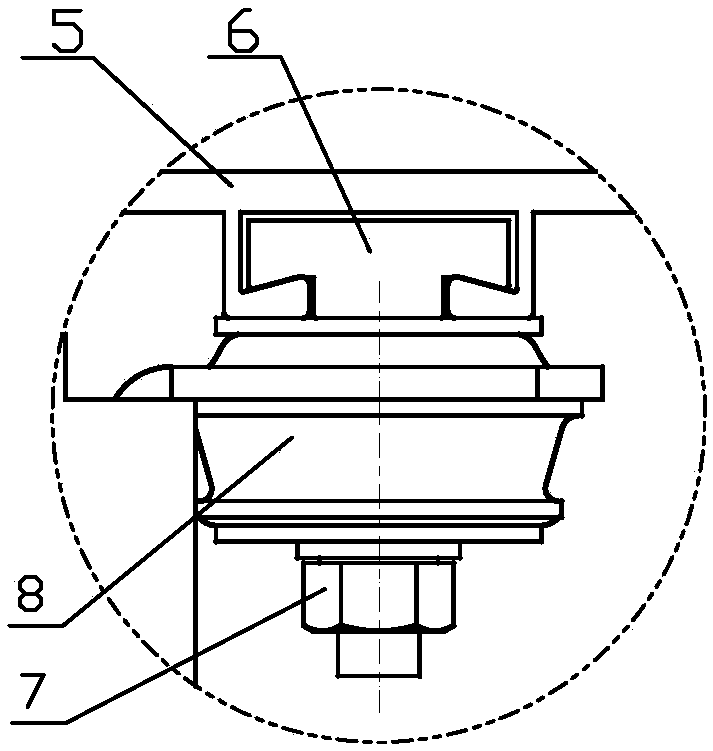

[0028] Specifically, such as image 3 , Figure 4 with Figure 5 As shown, the T-shaped chute 50 includes a screw receiving groove 51 and a locking groove 52, and the locking groove 52 has two sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com