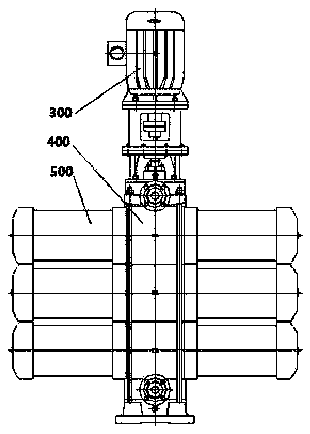

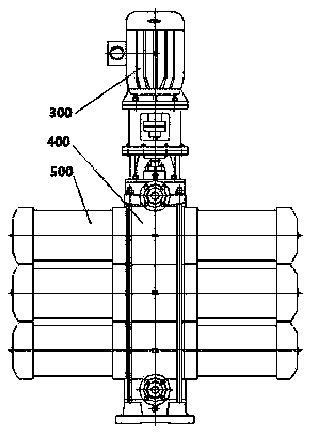

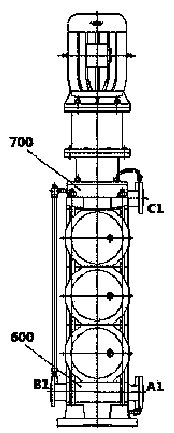

High pressure pump for sea water desalination

A high-pressure pump, seawater technology, applied in the direction of pumps, pump components, rotary piston pumps, etc., can solve the problems of large occupied space, uneven service life, low separation efficiency, etc., to achieve automatic operation control, easy maintenance and Maintenance, the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings. However, it should be understood that the embodiments disclosed herein are merely typical examples of the invention, which can be embodied in various forms. Therefore, specific details disclosed herein are not to be considered limiting, but merely as a basis for the claims and as a representative basis for teaching one skilled in the art to variously employ the invention in any appropriate way in practice, This includes taking various features disclosed herein and combining features that may not be expressly disclosed herein.

[0044] It should be noted that, herein, directional representations, such as "left", "right", "front", "rear", etc., used to explain the structure and / or action of various parts of the disclosed embodiments are not absolute. , but relative. These representations are appropriate when various parts of the disclosed embodiments are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com