Roof of light steel structure house

A technology for light steel structures and houses, which is applied to roofs, building roofs, building components, etc., can solve problems such as water leakage and life expectancy, and achieve the effects of high screw holding force, good stability, and reasonable roof structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

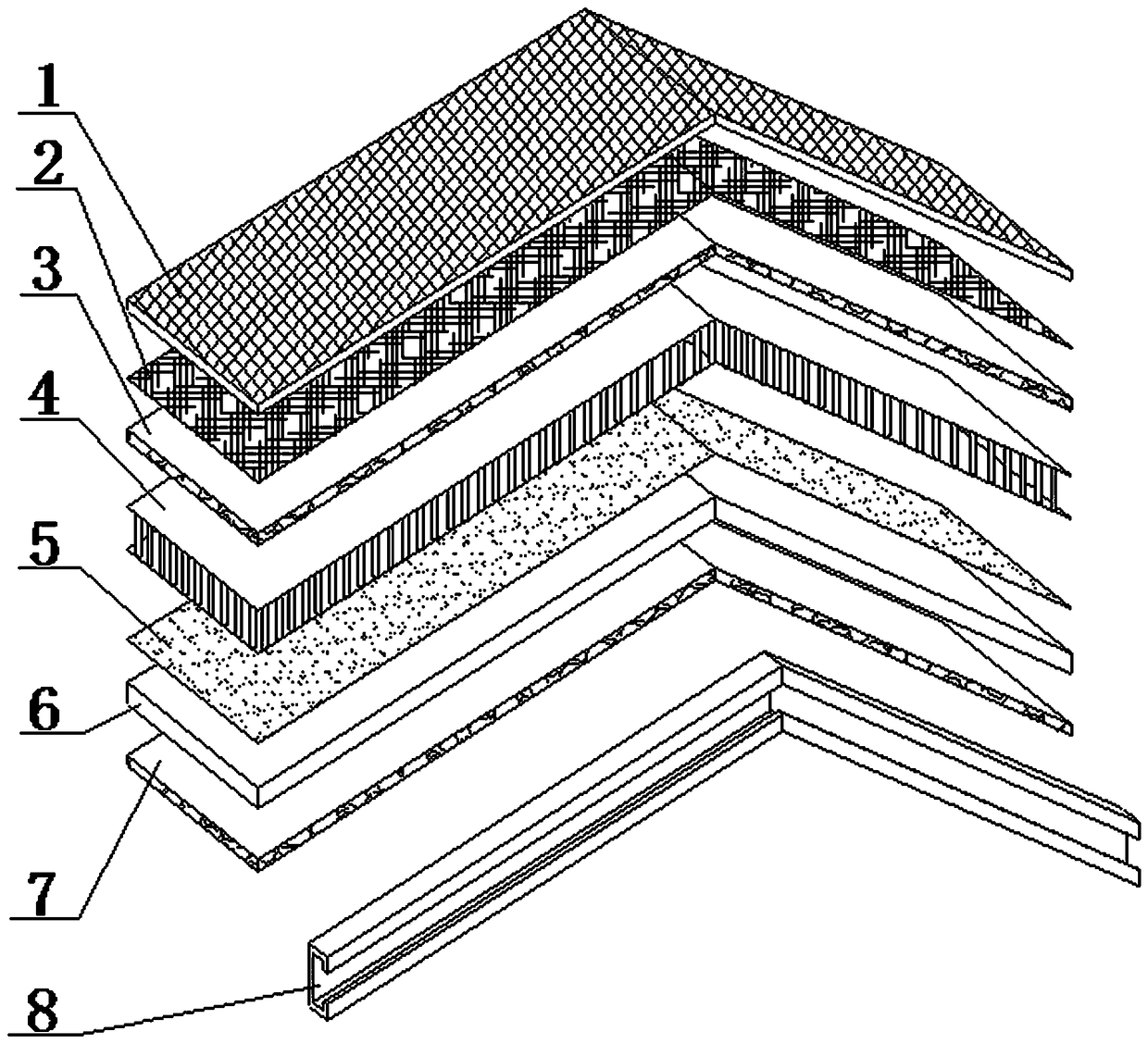

[0021] The roof of a light steel structure house consists of light steel keel 8, roof OSB board 7, insulation layer 6, ventilation layer 4, roof OSB board 3, waterproof layer 2 and roof asphalt tile 1 from inside to outside. The middle of the light steel keel is filled with thermal insulation materials, the middle of the ventilation layer is placed with a wooden keel, and the breathing paper 5 is pasted on the insulation layer.

[0022] The waterproof layer is a synthetic polymer waterproof coiled material whose thickness accounts for 8% of the total thickness of the roof. The synthetic polymer waterproof coiled material is composed of the following raw materials in parts by weight: 70 parts of EPDM rubber, 60 parts of epoxy resin, polyester 15 parts of styrene, 18 parts of maleic anhydride, 18 parts of poly-p-phenylene terephthalamide, 25 parts of porcelain powder, 3 parts of phthaloyl peroxide, 1.5 parts of dibutyl hydroxytoluene, 1-(N -Oxydiethylenethiocarbamoyl)-2-(N-oxydi...

Embodiment 2

[0031] The roof of a light steel structure house consists of light steel keel 8, roof OSB board 7, insulation layer 6, ventilation layer 4, roof OSB board 3, waterproof layer 2 and roof asphalt tile 1 from inside to outside. The middle of the light steel keel is filled with thermal insulation materials, the middle of the ventilation layer is placed with a wooden keel, and the breathing paper 5 is pasted on the insulation layer.

[0032] The waterproof layer is a synthetic polymer waterproof coiled material, whose thickness accounts for 10% of the total thickness of the roof. The synthetic polymer waterproof coiled material is composed of the following raw materials in parts by weight: 60 parts of EPDM rubber, 50 parts of epoxy resin, polypropylene 10 parts of styrene, 15 parts of maleic anhydride, 15 parts of poly-p-phenylene terephthalamide, 20 parts of porcelain powder, 2 parts of phthaloyl peroxide, 1 part of dibutyl hydroxytoluene, 1-(N 4 parts of -oxydiethylenethiocarbamo...

Embodiment 3

[0041] The roof of a light steel structure house consists of light steel keel 8, roof OSB board 7, insulation layer 6, ventilation layer 4, roof OSB board 3, waterproof layer 2 and roof asphalt tile 1 from inside to outside. The middle of the light steel keel is filled with thermal insulation materials, the middle of the ventilation layer is placed with a wooden keel, and the breathing paper 5 is pasted on the insulation layer.

[0042] The waterproof layer is a synthetic polymer waterproof coiled material whose thickness accounts for 6% of the total thickness of the roof. The synthetic polymer waterproof coiled material is composed of the following raw materials in parts by weight: 80 parts of EPDM rubber, 70 parts of epoxy resin, polypropylene 20 parts of styrene, 20 parts of maleic anhydride, 20 parts of poly-p-phenylene terephthalamide, 30 parts of porcelain powder, 4 parts of phthaloyl peroxide, 2 parts of dibutyl hydroxytoluene, 1-(N 6 parts of -oxydiethylenethiocarbamoy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com