Building fireproof insulation board for public occasions

A technology for fire-proof insulation boards and public places, which is applied in the direction of heat preservation, fire protection, and building components. The effect of excellent fire resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

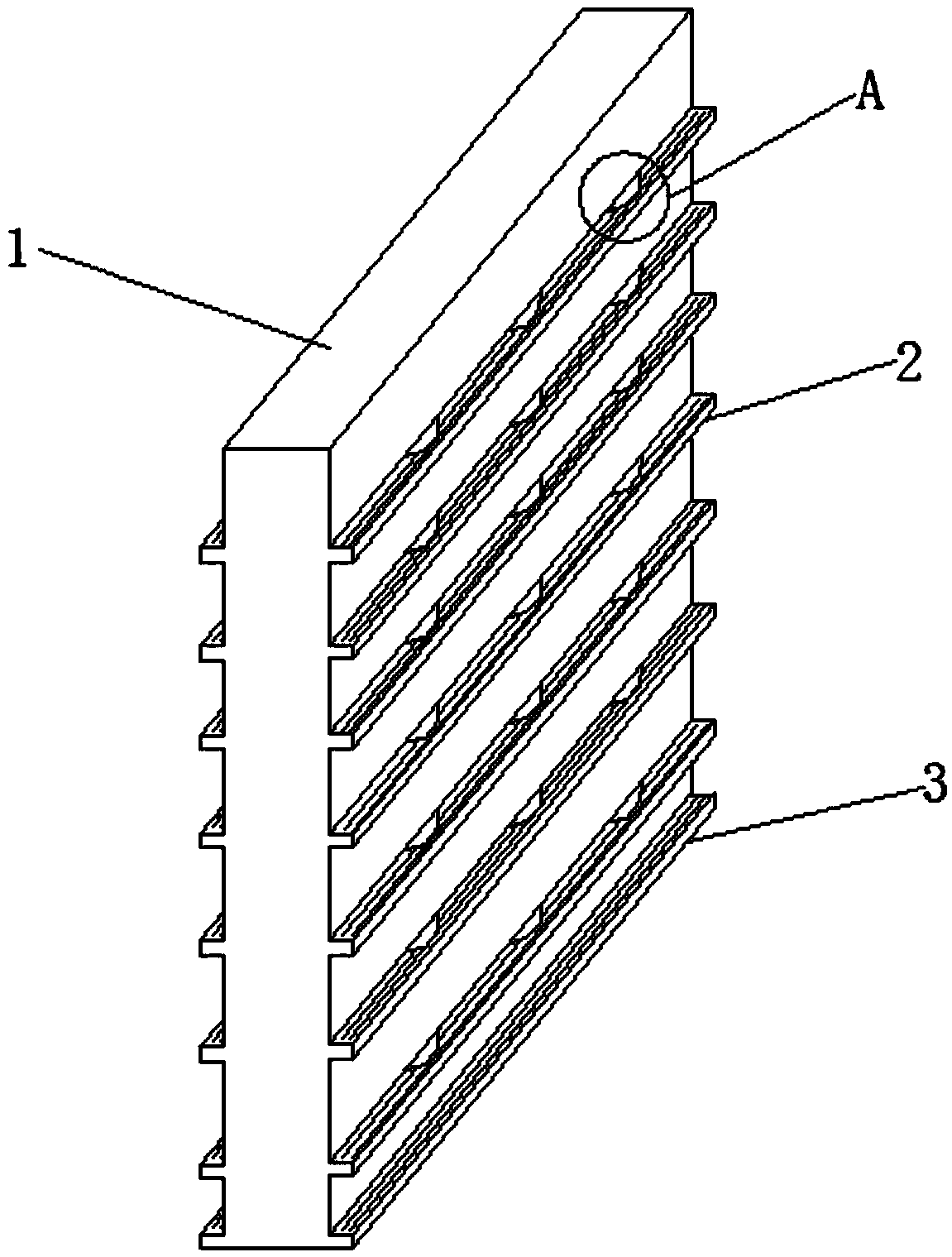

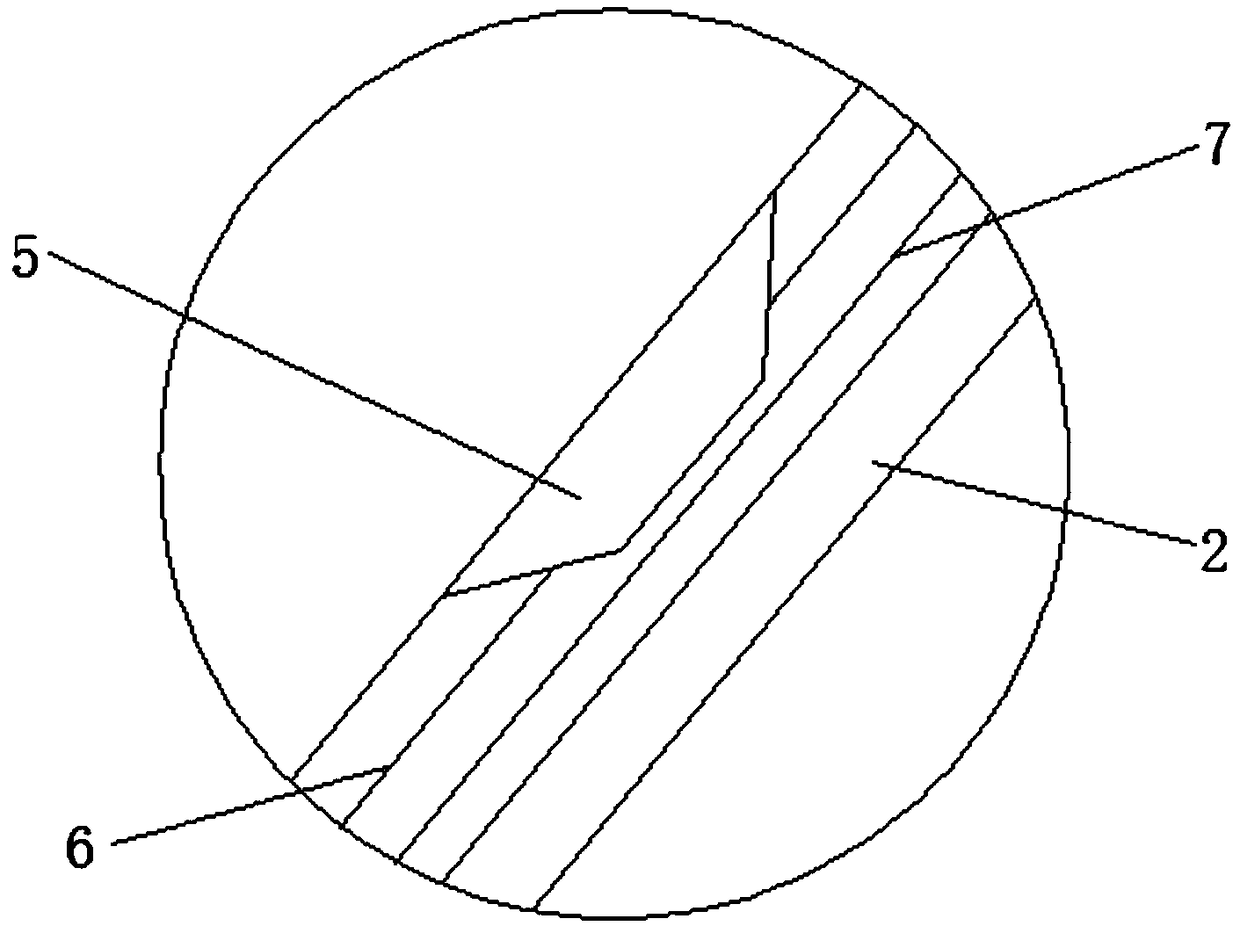

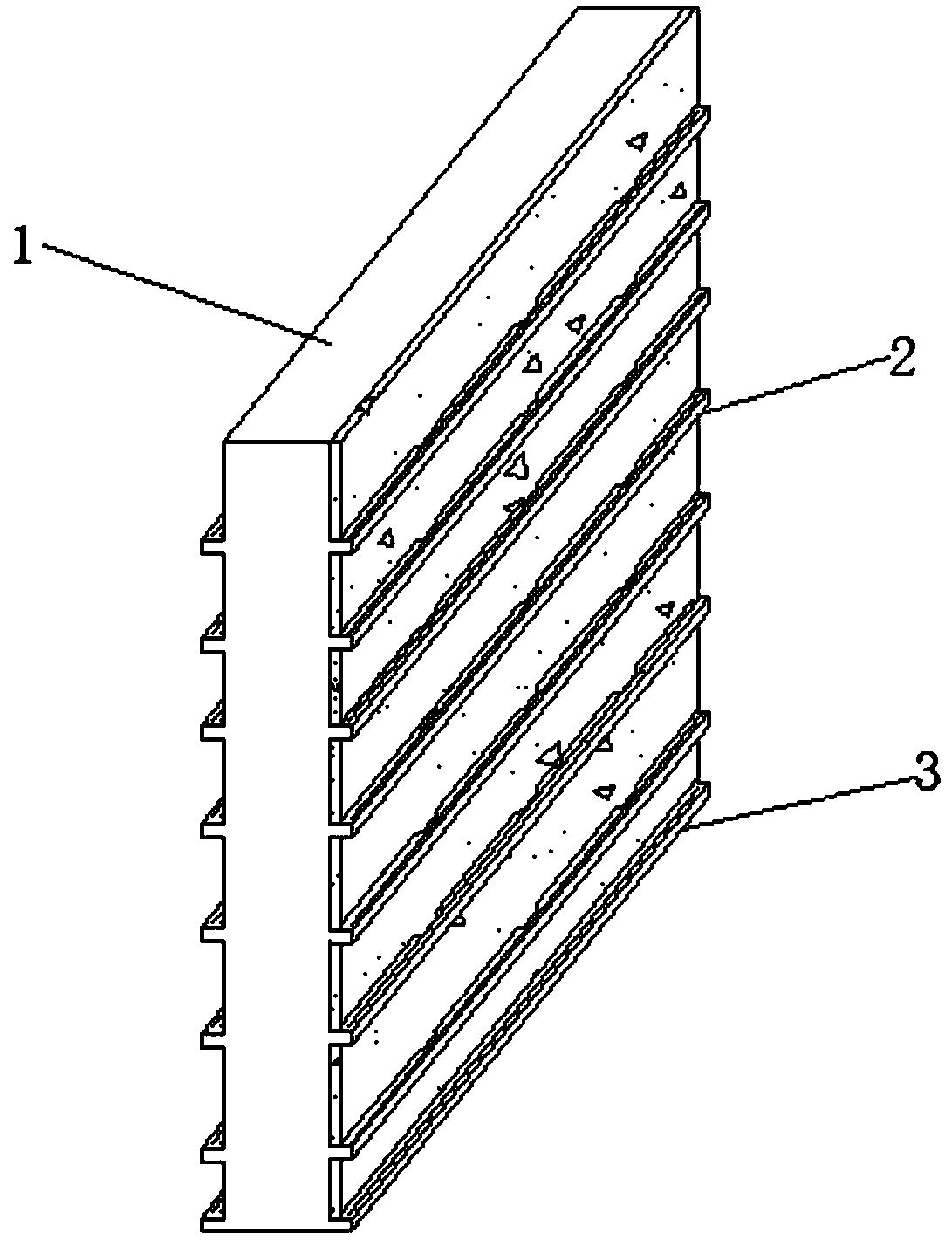

[0044] see figure 1 , a building fireproof insulation board for public places, comprising a fireproof insulation board main board 1 and a fireproof insulation coating 4, the fireproof insulation coating 4 is coated on the surface of the fireproof insulation board main board 1, and the fireproof insulation board main board 1 surface is connected with a plurality of first An auxiliary pallet 2, a plurality of first auxiliary pallets 2 are arranged horizontally on the main board 1 of the fireproof insulation board from top to bottom, and the end of the first auxiliary pallet 2 close to the main board 1 of the fireproof insulation board is excavated with a plurality of special-shaped leakage aids Through holes 5, a plurality of leakage-aiding special-shaped through holes 5 are evenly arranged horizontally on the first auxiliary supporting plate 2, and the bottom end of the main board 1 of the fireproof insulation board is connected with the second auxiliary supporting plate 3, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com