Cut-off device with capsule, distributing well and control system thereof

A technology of intercepting devices and diverting wells, which is applied in waterway systems, water supply devices, and sewage discharge, etc., can solve problems such as difficult power supply, electric shock hazards, and easy leakage of electricity, and achieves strong anti-winding and anti-blocking capabilities and does not occupy high space , cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] A shut-off device, comprising:

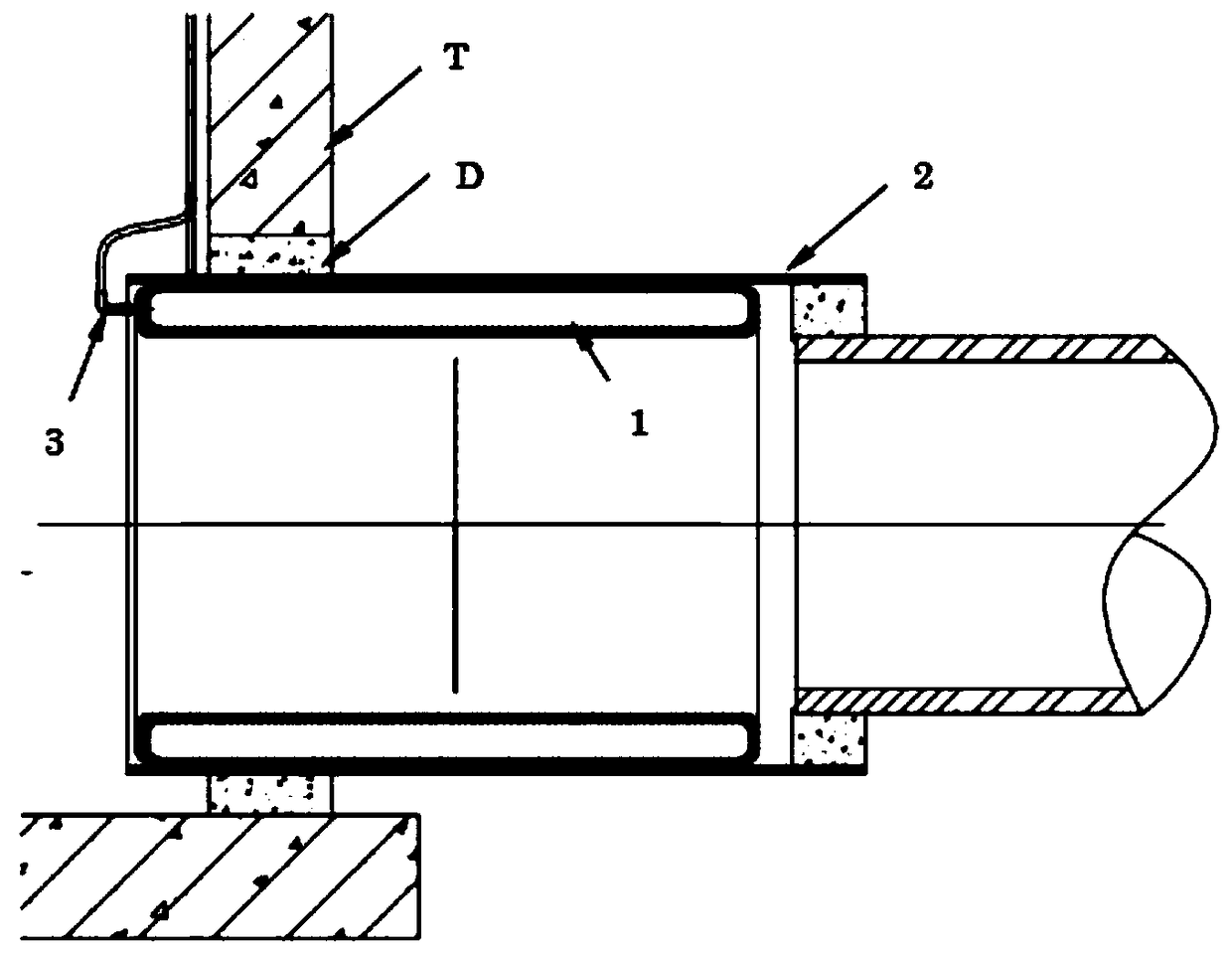

[0063] The capsule body 1 encloses a flow channel for fluid to pass through, and has an air cavity or a water cavity inside, and an inlet 3 is provided on the capsule body to communicate with the air cavity or the water cavity. Such as figure 1 As shown, the capsule body is a sandwich structure, and the cavity between the sandwich layers is an air cavity or a water cavity. Wherein the inlet 3 is arranged on the side wall of the capsule.

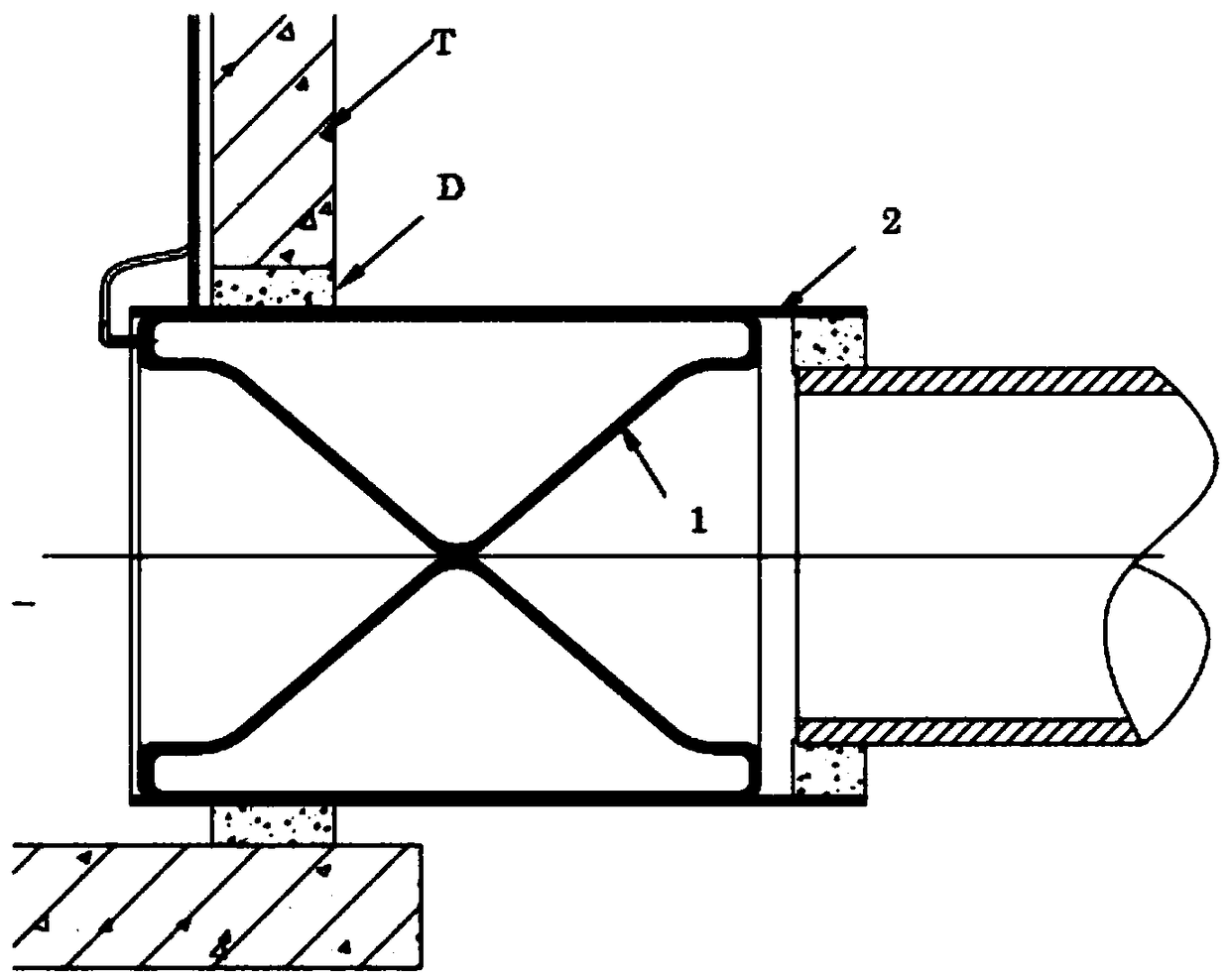

[0064] Outer cover 2, the cover is set outside the capsule, and the inner side of the outer cover is attached to the outer surface of the outer wall of the capsule. When the air cavity or water cavity is filled with pressurized gas or pressurized water, the outer wall of the capsule is attached to the inner wall of the outer cover. However, the inner wall of the capsule deforms and expands inwardly, so that the cross-sectional area of the circulation channel becomes smaller.

[0065] In this case, ...

Embodiment 2

[0067] On the basis of Example 1, in order to prevent the capsule from being displaced and being washed away by the fluid in the cut-off state, two front and rear stoppers can be provided on the inner wall of the outer cover, and the capsule snaps into the two stoppers Clamped in place.

[0068] Preferably, the limiting member is a ring, and the outer end is welded and fixedly connected to the inner wall of the outer cover.

Embodiment 3

[0070] Such as figure 1 , 2 As shown, on the basis of the above-mentioned embodiments 1-2, the cross-sections of the outer cover and the capsule body are circular, and the outer cover and the capsule body are coaxially arranged. The capsule body is a rubber capsule, which is integrally cast by lost foam. Elastic materials of different materials can also be selected according to the fluid properties of the actual fluid. When the air cavity or water cavity is filled with pressurized air or water, the capsule body The inner wall deforms inward under the action of pressure, so that the cross-sectional area of the flow channel, that is, the water passing area, gradually decreases, and can also be cut off. According to the required water flow, the water passing area of the flow channel can be adjusted, and the rubber sleeve stays at any position.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com