High-performance LF refining slag

A refining slag, high-performance technology, applied in the field of refining slag, can solve problems such as easy crusting, melting point of refining slag, and unsatisfactory viscosity and foaming properties, and achieve the effect of reducing the quantity

Active Publication Date: 2019-02-15

NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

View PDF4 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the refining slag obtained by the above technical solution also has unsatisfactory melting point, viscosity, and foamability, and also has the problem of easy crusting

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1-11

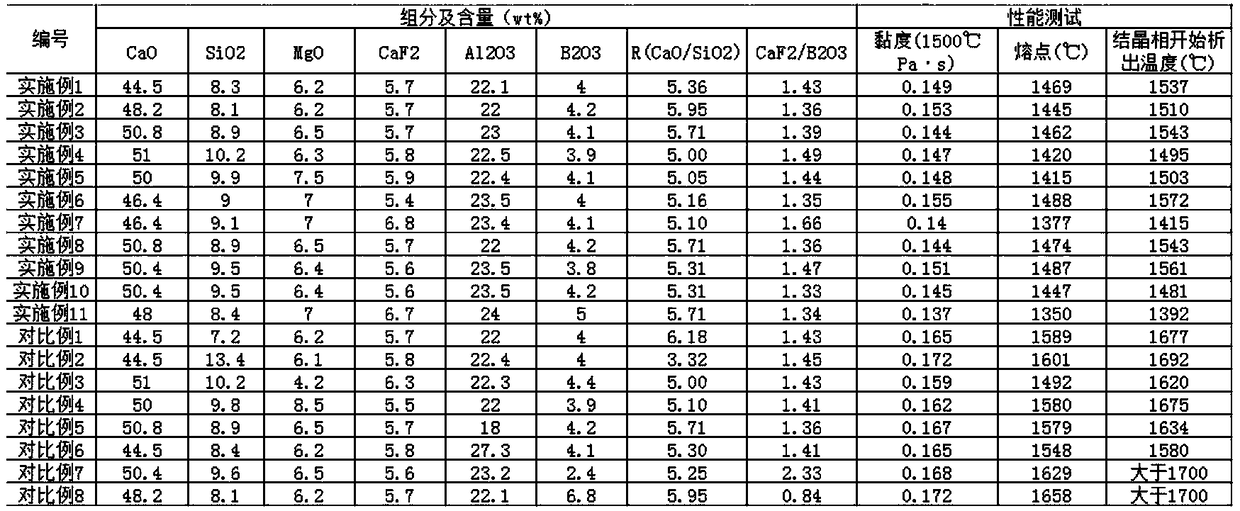

[0018] A kind of LF refining agent, including the components shown in Table 1.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention provides high-performance LF refining slag. The high-performance LF refining slag comprises following components including 44%-51% of CaO, 8%-12% of SiO2, 6%-8% of MgO, 5%-7% of CaF2, 22%-25% of Al2O3 and 3%-5% of B2O3, and binary basicity R(CaO / SiO2) is 5-6. The obtained LF refining slag has proper viscosity and a proper melting point, separation of a high-melting-point mine phase is well controlled while the phenomenon of refining slag crusting cannot happen in the refining process, and the number of inclusions in steel is effectively reduced.

Description

technical field [0001] The invention relates to a refining slag, in particular to an LF refining slag. Background technique [0002] The basic function of refining slag is to remove inclusions, sulfur and oxygen in molten steel and other elements that will adversely affect steel quality, purify molten steel, prevent molten steel from absorbing gas, and reduce heat loss. LF refining slag is divided into basic slag (CaO-Al 2 o 3 slag system), flux (CaF 2 ), foaming agent (silicon carbide, calcium carbide), etc., the mutual reaction of each component produces a refining slag with low melting temperature, moderate viscosity, good foaming performance, and good deoxidation and desulfurization performance, and obtains better metallurgical effects. High quality special steel. [0003] The Chinese invention patent with the publication number CN101956045A discloses a refining slag containing the following components in parts by weight: 40-55 parts of CaO, 30-45 parts of SiO2, 10-2...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C21C7/06C21C7/064

CPCC21C7/06C21C7/0645

Inventor 李俊国曾亚南

Owner NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com